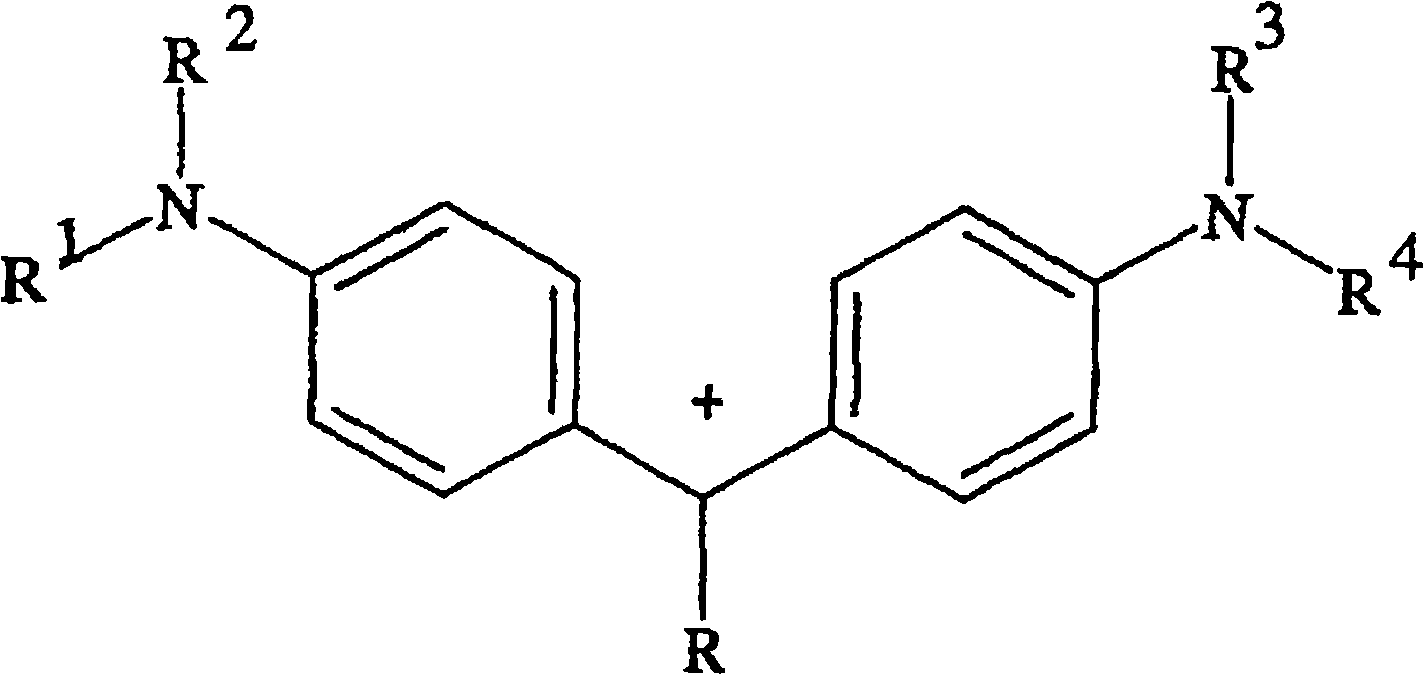

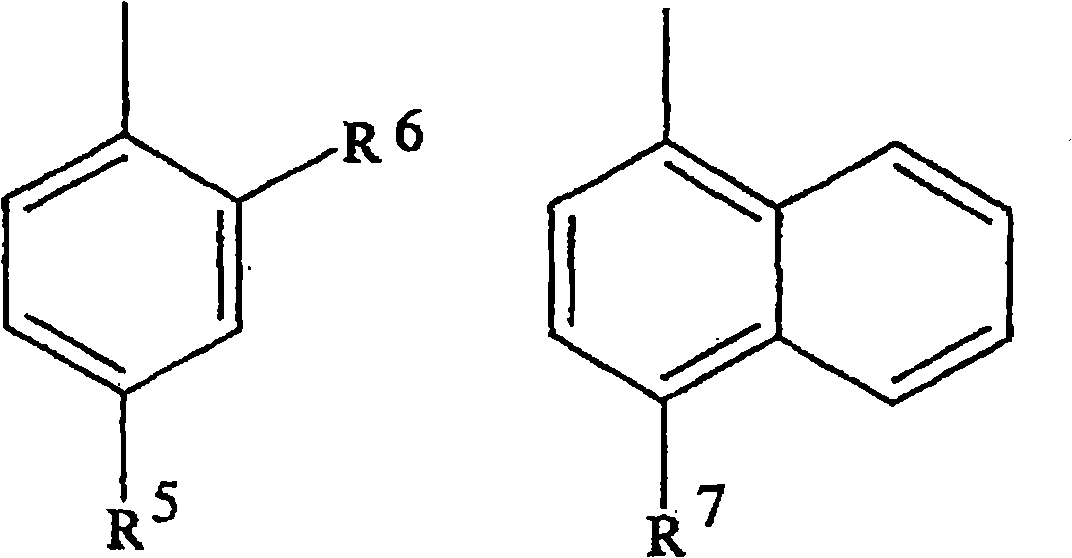

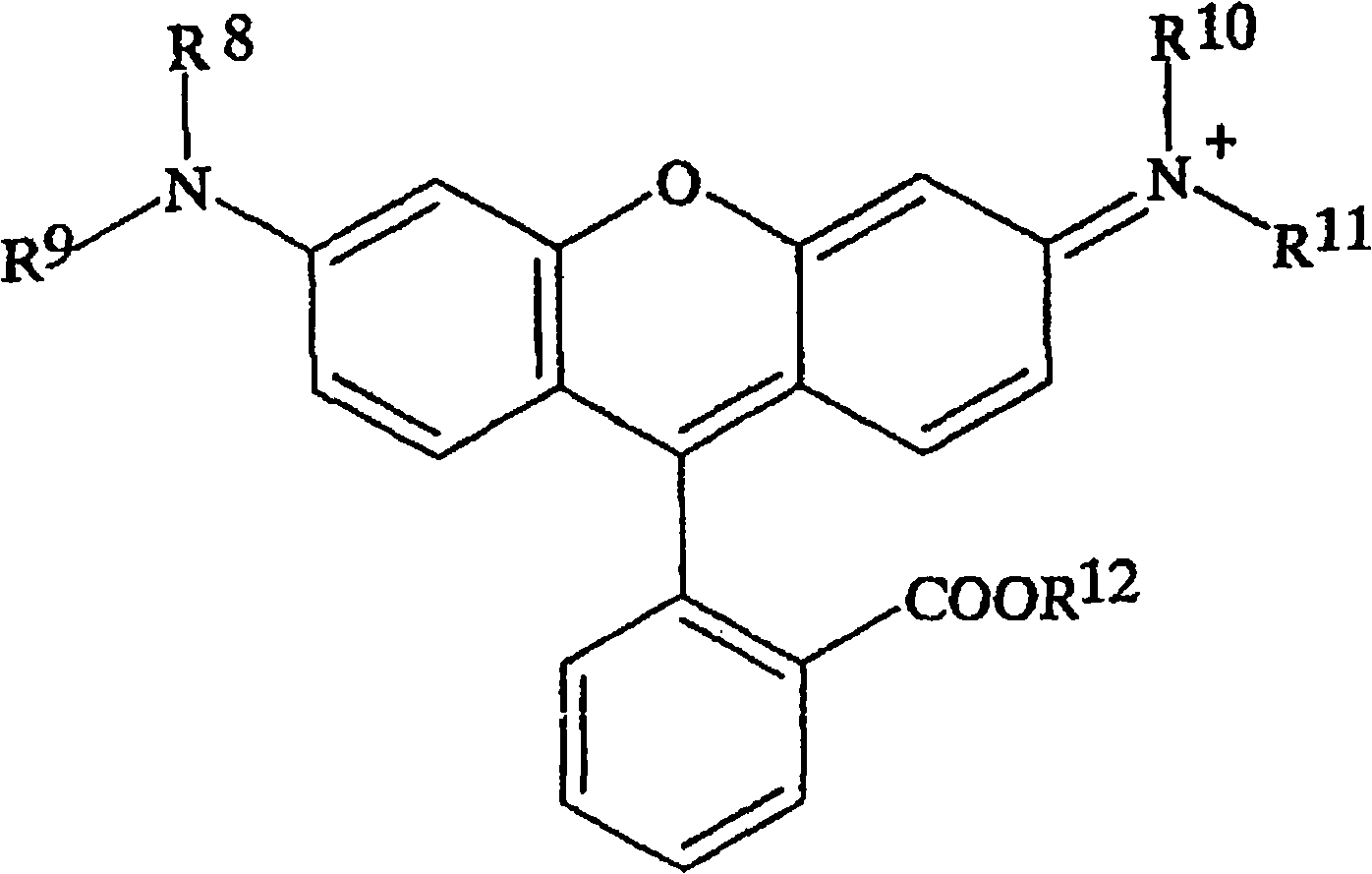

Pigment composition of triarylmethane and rhodamine, and pigment dispersion using same

A technology of pigment composition and pigment dispersion, applied in the direction of pigment slurry, azo dyes, organic dyes, etc., can solve the problems of poor heat resistance and light resistance, and achieve the effect of excellent light resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] As shown in Table 1, add 10 parts of untreated C.I. Pigment Blue 1 and 1 part of sodium 2-naphthalenesulfonate to 250 parts of 2.5% acetic acid aqueous solution, stir thoroughly with a disperser, raise the temperature to 80°C and stir for 2 hours . The obtained slurry was filtered, and the precipitate was washed with water, and dried overnight at 80° C. to obtain 9.9 parts of the target pigment composition.

[0045] 5 parts of the pigment composition, 36.7 parts of propylene glycol monomethyl ether acetate, and 8.3 parts of a polymer dispersant (BYK 170, manufactured by BYK Chemie Japan Co., Ltd.) were added to the lacquer together with 0.5 mm zirconia beads. After dispersing in the bottle for 1 hour with a paint conditioner, 0.2 parts of an acrylic resin (SPC-2000, Showa Polymer Co., Ltd.) was added to obtain a blue pigment dispersion.

Embodiment 2~11

[0047] The blue pigment dispersions of Examples 2-11 were obtained by the same method as Example 1 using each component shown in Table 1. It should be pointed out that in Examples 9 and 10, the surfactant was added to the aqueous acetic acid solution together with 1 part of C.I. Pigment Blue 1 and 1 part of sodium 2-naphthalenesulfonate.

Embodiment 12~13

[0061] As shown in Table 2, 4.65 parts of untreated C.I. Pigment Blue 1, 0.35 parts of sodium 2-naphthalenesulfonate, 36.7 parts of propylene glycol monomethyl ether acetate, 8.3 parts of polymer dispersant (BYK 170, BYK Chemie Japan (manufactured by the company) and φ0.5mm zirconia beads were added to the paint bottle, and after dispersing with a paint conditioner for 1 hour, 0.2 parts of acrylic resin (SPC-2000, Showa Polymer Co., Ltd.) was added to obtain a blue pigment dispersion body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com