Integrated detector for micro-force micro-displacement measurement system

A measurement system and detector technology, applied in the field of integrated detectors, can solve the problems of low displacement and micro force measurement accuracy, inconvenient installation and system integration, complex optical system structure, etc. The effect of system volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

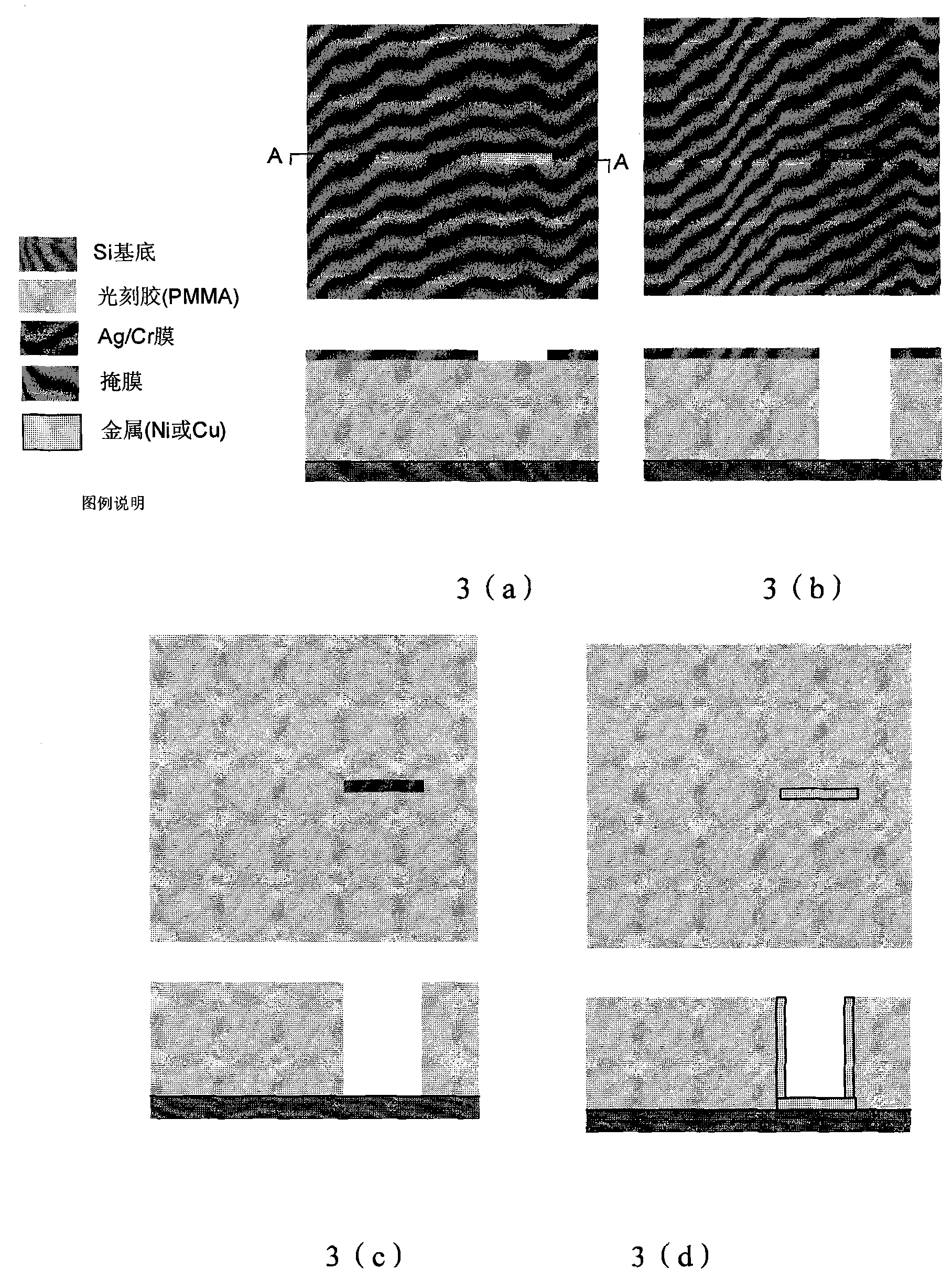

[0031] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

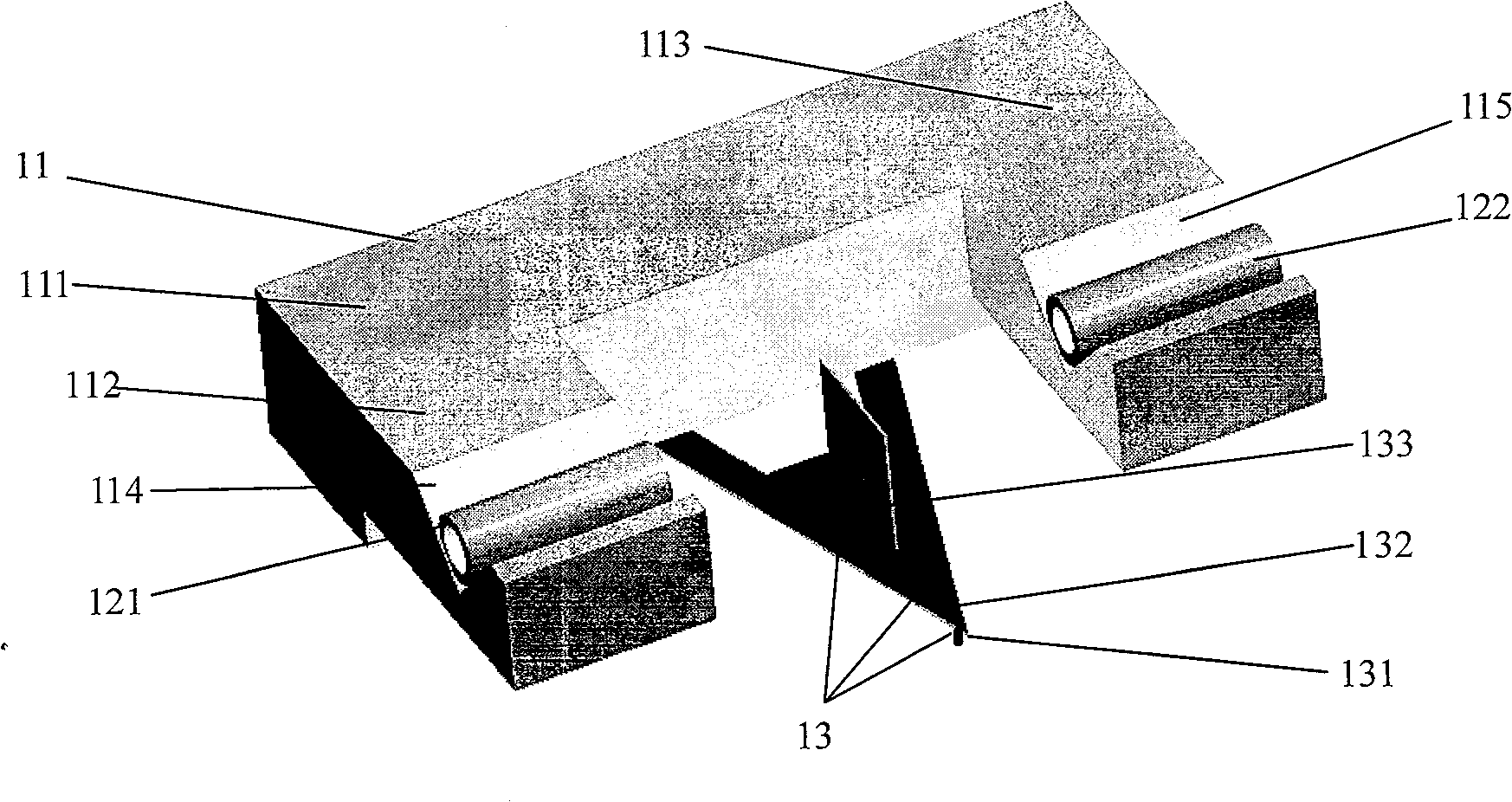

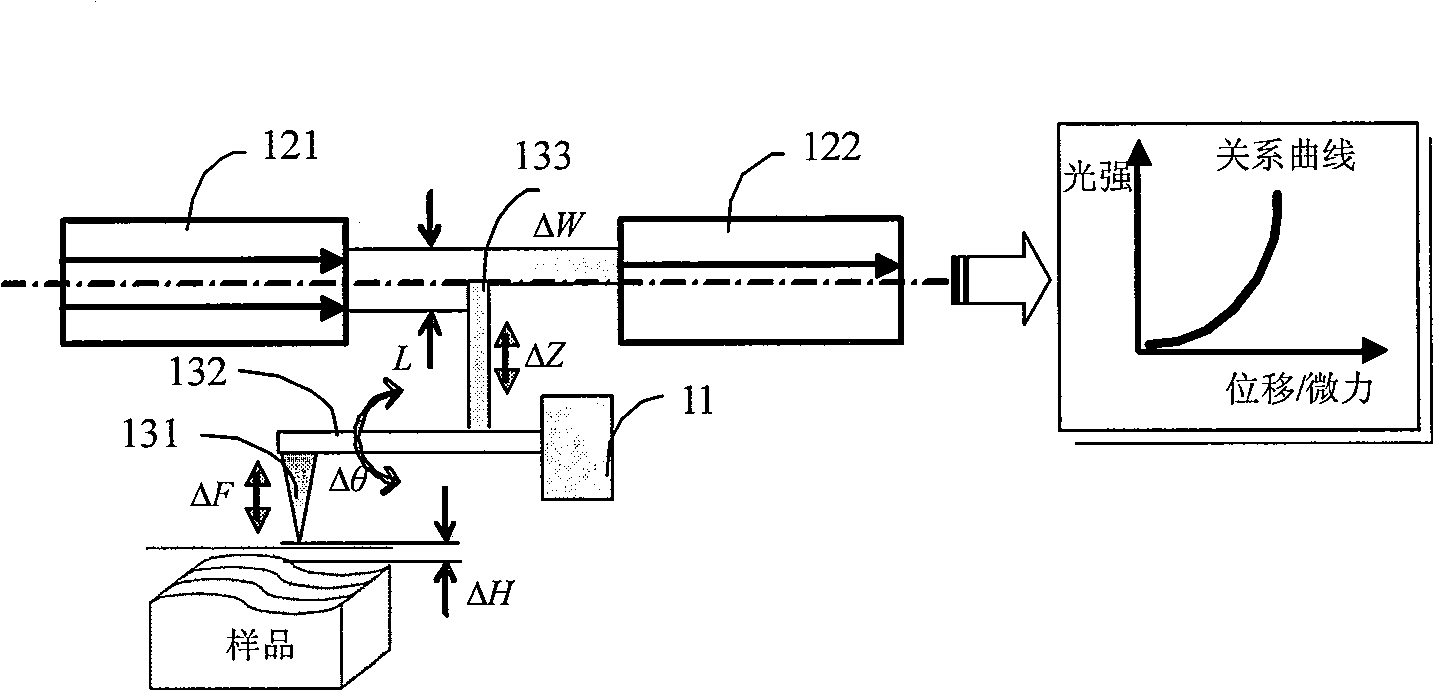

[0032] refer to figure 1 , which shows a structure diagram of an embodiment of an integrated detector for a micro-force and micro-displacement measurement system according to the present invention, the detector includes: a fixing frame 11, an optical fiber sensing module and a micro-detecting module 13;

[0033] The fixed frame 11 is a U-shaped fixed frame, including a base 111, and a symmetrical left arm 112 and a right arm 113 located at both ends of the base; the left arm is provided with a left V-shaped groove 114, and the right arm There is a right V-groove 115 on the top;

[0034] The optical fiber sensing module includes: a transmitting optical fiber 121 and a receiving optical fiber 122, which are used to detect changes i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com