LCD panel and manufacturing method thereof

A technology for a liquid crystal display panel and a manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of unstable product quality and display characteristics of liquid crystal display panels, liquid crystal pollution, etc., to reduce the probability of pollution and slow down the diffusion speed. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

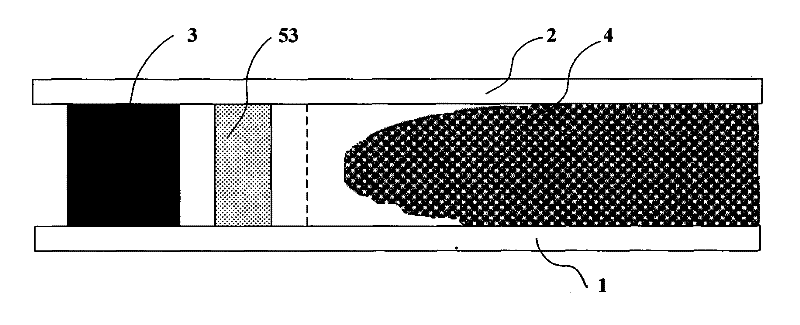

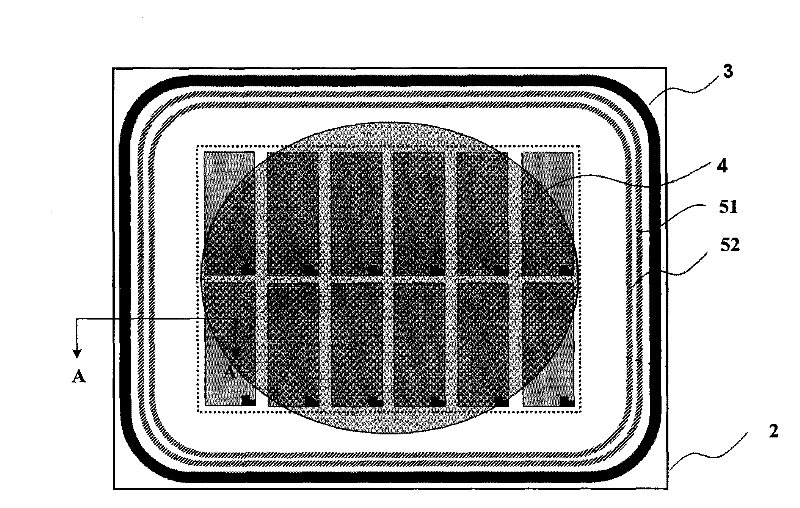

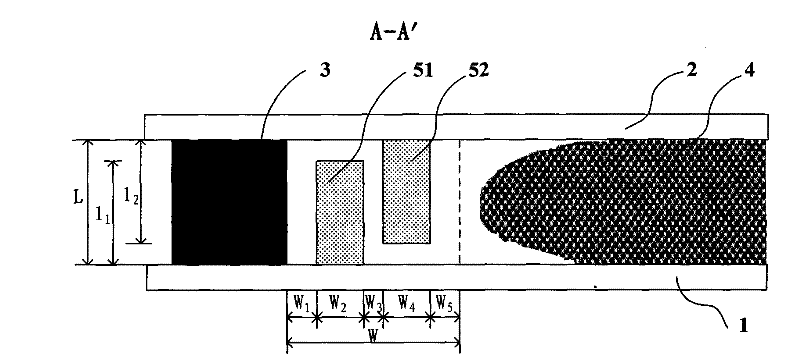

[0028] figure 2 The top view of the liquid crystal display panel during the liquid crystal diffusion process provided by the first embodiment of the present invention; image 3 for figure 2 A-A' sectional view of the liquid crystal display panel shown. Such as figure 2 with image 3 As shown, the liquid crystal display panel of this embodiment includes an array substrate 1 and a CF substrate 2, and the CF substrate 2 and the array substrate 1 are arranged opposite to each other up and down, wherein the display area of the CF substrate 2 (the area indicated by the dotted line in the figure) and the array substrate 1 corresponds to the display area, and the peripheral area of the CF substrate 2 (ie, the non-display area) corresponds to the peripheral area of the array substrate 1 . The area between the display area of the CF substrate 2 and the display area of the array substrate 1 is a liquid crystal filling area, and liquid crystal 4 is filled in the liquid cr...

Embodiment 2

[0042] Figure 4 The top view of the liquid crystal display panel during the liquid crystal diffusion process provided by the second embodiment of the present invention; Figure 5 for Figure 4 B-B' sectional view of the liquid crystal display panel shown. Such as Figure 4 with Figure 5 As shown, the difference from Embodiment 1 of the present invention is that in this embodiment, two first barrier layers 51 are formed on the peripheral region of the array substrate 1 , and two second barrier layers 52 are formed on the peripheral region of the CF substrate 2 . The first barrier layers 51 and the second barrier layers 52 are arranged in parallel, alternately and at equal intervals. Figure 4 with Figure 5 Only the liquid crystal distribution during the liquid crystal diffusion process is shown, and those skilled in the art can understand that after the liquid crystal diffusion is completed, between the second barrier layer 52 and the array substrate 1, between the firs...

Embodiment 3

[0046] Image 6 It is a top view of the liquid crystal display panel provided by the third embodiment of the present invention. Such as Image 6 As shown, the difference from Embodiment 1 of the present invention is that the cross-sectional shape of the first barrier layer 51 and the second barrier layer 52 in this embodiment is a rounded rectangle, and a conduction peripheral area and a conductive peripheral area are formed at the rounded corners of the rounded rectangle. Opening 7 in the display area.

[0047] In the process of implementing the embodiment of the present invention, the inventors found that during the process of aligning liquid crystal display panels, due to the internal tension of the liquid crystal, the trajectory of the liquid crystal 4 spreading from the central part of the display area to the surroundings usually appears as an ellipse, and it can be seen that the liquid crystal 4 4 The probability that the liquid crystal 4 diffuses to the peripheral are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com