Short arc type discharge lamp

A discharge lamp and short-arc technology, applied to discharge lamps, gas discharge lamps, high-pressure discharge lamps, etc., can solve problems such as overheating, hypertrophy, and illuminance drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

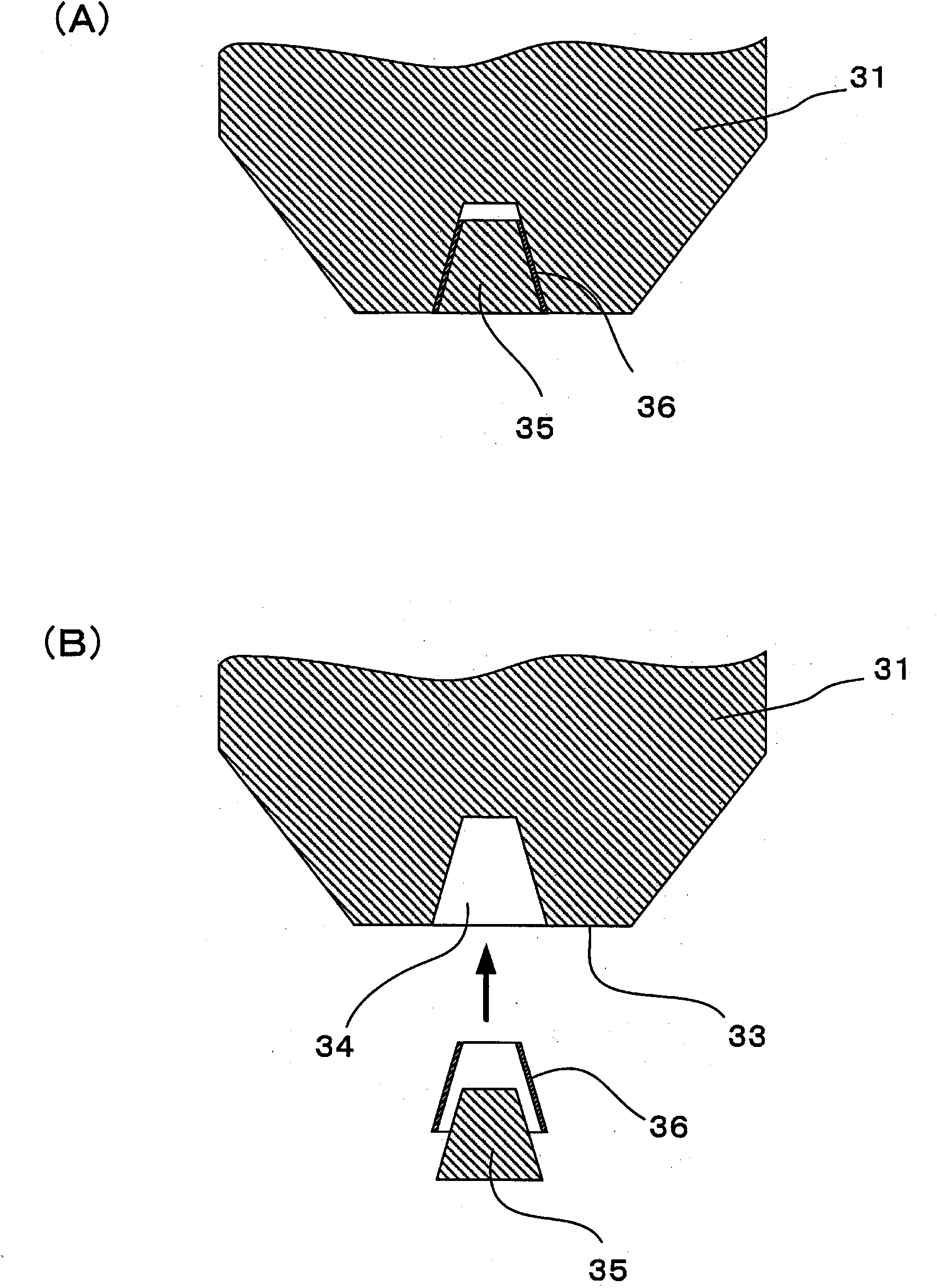

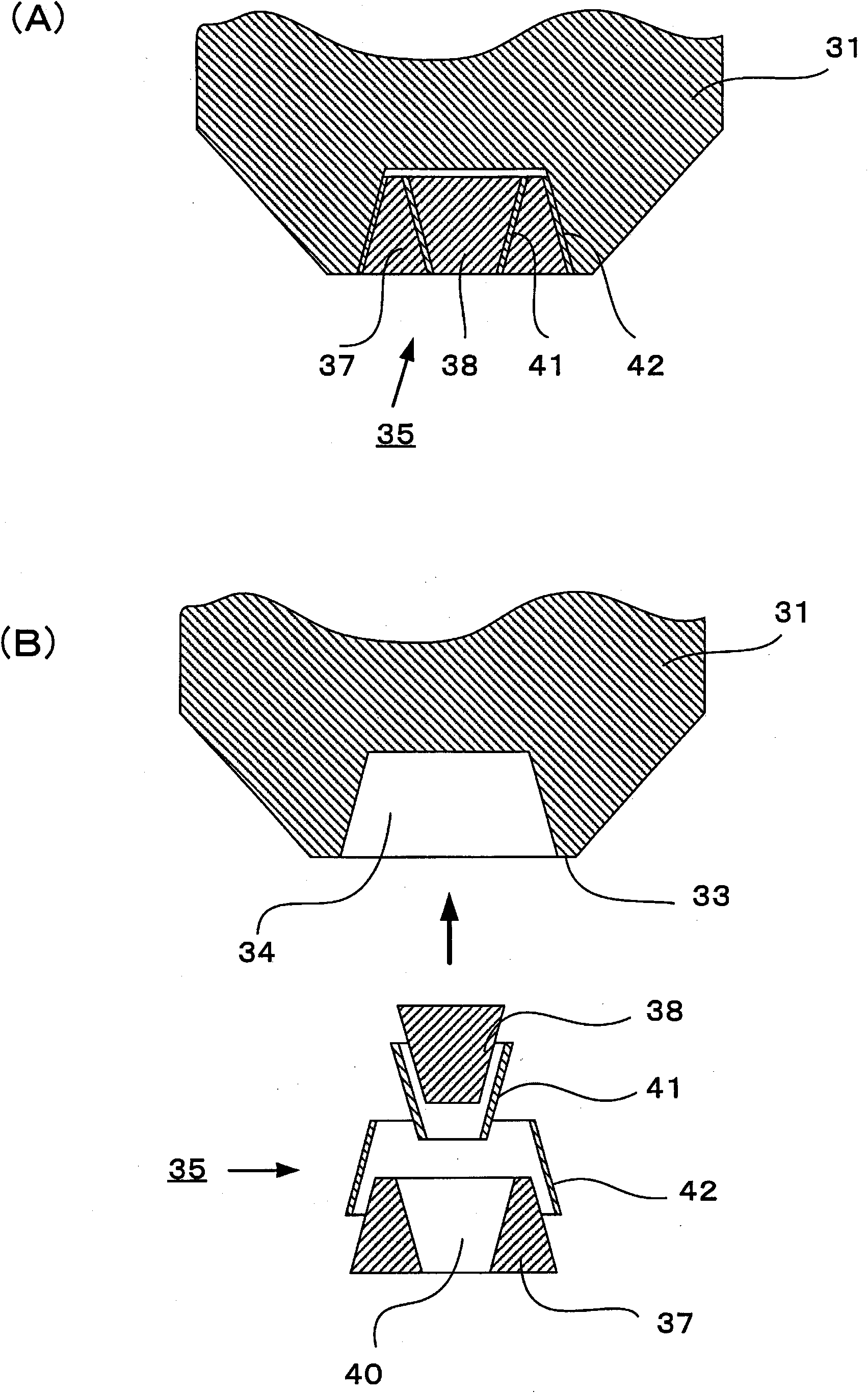

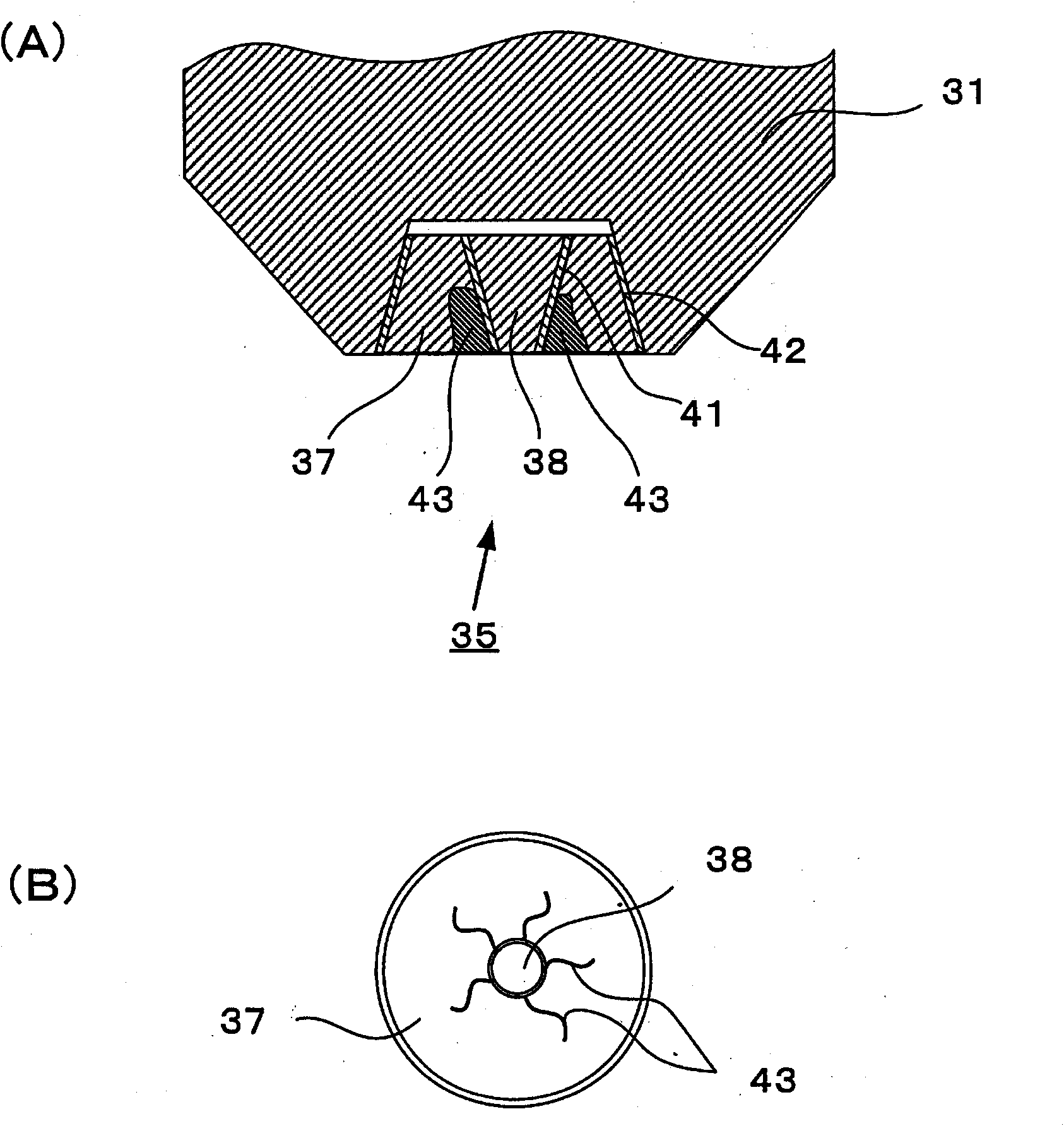

[0042] figure 1 It is a cross-sectional view of the first embodiment, (A) is an assembly cross-sectional view, and (B) is an explanatory view of an assembly process.

[0043] In the drawing, an opening 34 opening on the front end surface of the anode 31 is formed at the central portion of the front end surface 33 . Separately from the anode 31, an insertion body 35 made of the same material as the anode is formed in a shape matching the opening 34, and the insertion body 35 sandwiches the buffer member 36 therebetween and is pressed by means of driving or the like. inserted into the opening 34.

[0044] Specifically, an insertion body 35 made of tungsten is inserted into the opening 34 of the front end surface of the anode 31 made of tungsten. conical.

[0045] The buffer member 36 is made of a metal material that has a smaller yield stress than the anode 31 and the insert 35 at the same temperature, specifically, it is made of tantalum, molybdenum, niobium, or rhenium, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com