Method for enhancing running durability of fuel cell

A fuel cell, fuel cell stack technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

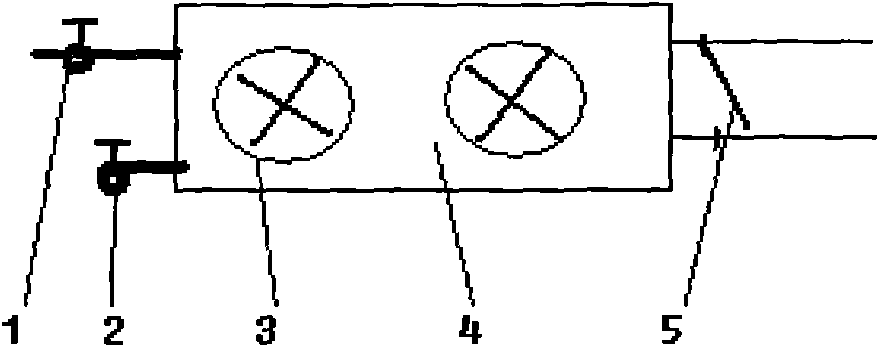

[0032] Such as figure 1 Shown is a schematic diagram of the system structure of a 200W air-cooled fuel cell, the air-cooled fuel cell stack 4 is provided with a cooling fan 3, the hydrogen inlet of the air-cooled fuel cell stack 4 is provided with a solenoid valve 1, and the hydrogen outlet is provided with a solenoid valve 2 , the voltage output end of the air-cooled fuel cell stack 4 is provided with a controllable switch 5, and the operating life of the fuel cell is improved by setting the shutdown procedure of the fuel cell, mainly by increasing the temperature of the fuel cell after shutdown, and by setting the controllable switch 5 so that The fuel cell is kept at zero voltage, and the treatment method is under the condition that the cathode is short of oxygen.

[0033] The shutdown procedure specifically includes the following process: when the fuel cell needs to be shut down after running for a period of time, the cooling fan 3 stops running. At this time, the hydrogen...

Embodiment 2

[0040] A method for improving the operating durability of a fuel cell, the method is to improve the operating life of the fuel cell by setting a shutdown program for the fuel cell, and the shutdown program specifically includes the following steps:

[0041] (1) Keep the hydrogen supply on the anode side of the fuel cell so that the fuel hydrogen is in a sufficient state;

[0042] (2) Turn off the air supply fan on the cathode side of the fuel cell;

[0043] (3) A controllable switch is connected to the output end of the fuel cell, so that the fuel cell has sufficient hydrogen on the anode side and insufficient oxygen supply on the cathode side, the controllable switch is turned off, so that the positive and negative poles of the voltage output end of the fuel cell are connected, and the fuel The battery is short-circuited; the cathode side of the fuel cell is relatively open, and the air flow path on the cathode side is relatively short. In the absence of a fan for forced air ...

Embodiment 3

[0046] A method for improving the operating durability of a fuel cell, the method is to improve the operating life of the fuel cell by setting a shutdown program for the fuel cell, and the shutdown program specifically includes the following steps:

[0047] (1) Keep the hydrogen supply on the anode side of the fuel cell so that the fuel hydrogen is in a sufficient state;

[0048] (2) Turn off the air supply fan on the cathode side of the fuel cell;

[0049] (3) A controllable switch is connected to the output end of the fuel cell, so that the fuel cell has sufficient hydrogen on the anode side and insufficient oxygen supply on the cathode side, the controllable switch is turned off, so that the positive and negative poles of the voltage output end of the fuel cell are connected, and the fuel The battery is short-circuited; the cathode side of the fuel cell is relatively open, and the air flow path on the cathode side is relatively short. In the absence of a fan for forced air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com