Livestock breeding wastewater nutrient pollution control and recycling process

A livestock and poultry breeding wastewater and pollution control technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of difficult discharge standards and restrictions on livestock and poultry breeding Issues such as wastewater discharge up to standard and resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

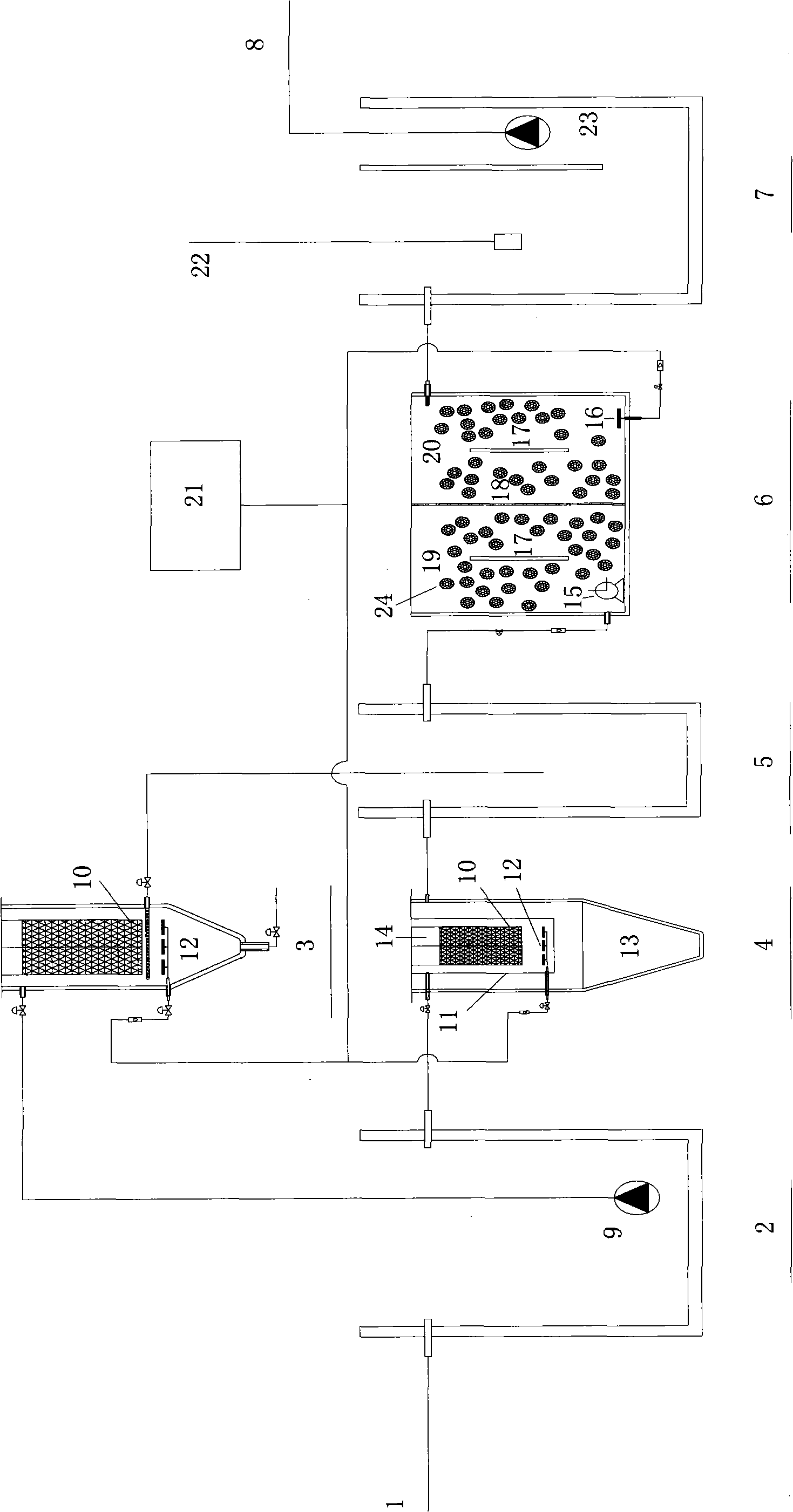

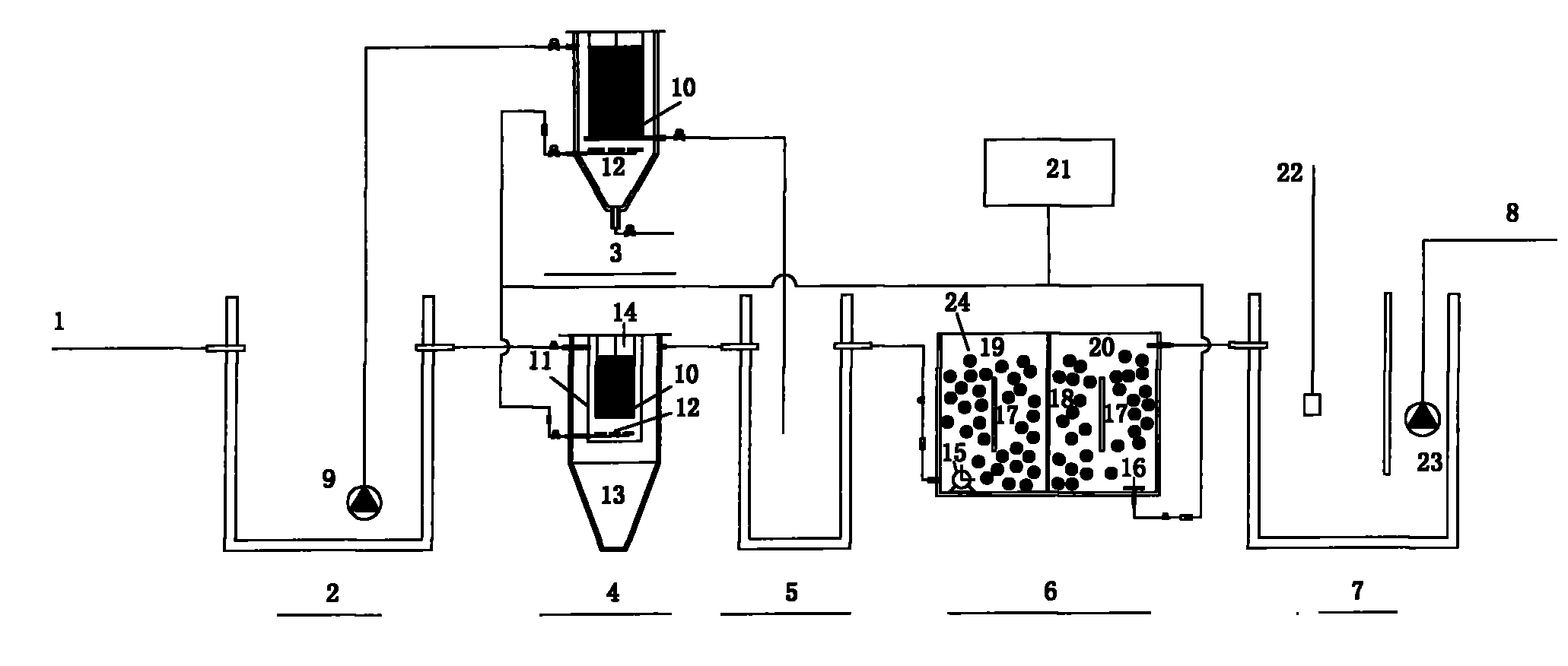

[0024] The livestock and poultry breeding wastewater (average water quality is COD 1753.7mg / L, TP 52.9mg / L, PO 4 3- -P 39.5mg / L, NH 4 + -N 646.6mg / L, Mg 60mg / L, pH 7.06, alkalinity 60mmol / L), at 0.28m 3 The flow rate of / h is injected into the pre-regulation tank. After adjusting the water quality and quantity, it is injected into the sequence batch MAP reactor and the continuous flow MAP reactor respectively; the sequence batch MAP reactor has a reactor height of 2.5m, a diameter of 1.0m, and an effective volume 1.0m 3 , the crystal trap is set inside. The trap is made of stainless steel wire mesh and is in the shape of four concentric cylinders with a diameter of 0.8m and a height of 1.0m. The bottom of the reactor is a conical crystal collection bucket for collecting MAP crystals that cannot be trapped by the trap; The sequence batch MAP reactor adopts the SBR operation mode, the water intake is 0.5h, the aeration reaction is 2h, the precipitation is 1h, the water outl...

Embodiment 2

[0029] The livestock and poultry breeding wastewater (average water quality is COD 1765.6mg / L, TP 59.4mg / L, PO 4 3- -P 41.0mg / L, NH 4 + -N 650.1mg / L, Mg 65mg / L, pH 7.12, alkalinity 62mmol / L), at 0.42m 3 The flow rate of / h is injected into the pre-regulation tank. After adjusting the water quality and quantity, it is injected into the sequence batch MAP reactor and the continuous flow MAP reactor respectively; the sequence batch MAP reactor has a reactor height of 2.5m, a diameter of 1.0m, and an effective volume 1.0m 3, the crystal trap is set inside. The trap is made of stainless steel wire mesh and is in the shape of four concentric cylinders with a diameter of 0.8m and a height of 1.0m. The bottom of the reactor is a conical crystal collection bucket for collecting MAP crystals that cannot be trapped by the trap; The sequence batch MAP reactor adopts the SBR operation mode, the water intake is 0.5h, the aeration reaction is 0.5h, the precipitation is 1.5h, the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com