Circular inoculation method used for accelerating fermentation process of municipal sludge dry method

A technology of dry fermentation and municipal sludge, which is applied in the field of solid waste recycling, can solve the problems of being unsuitable for sludge dry fermentation process, difficult enrichment of methanogenic bacteria, and high viscosity of reaction substrate, so as to shorten the transition time, Effect of strengthening microbial function and strengthening ecological function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

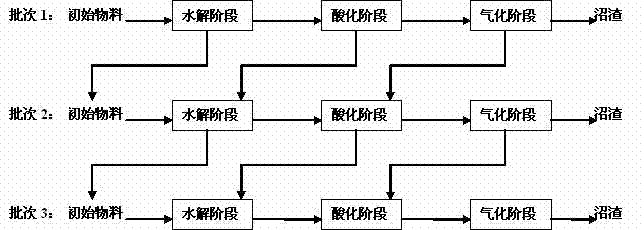

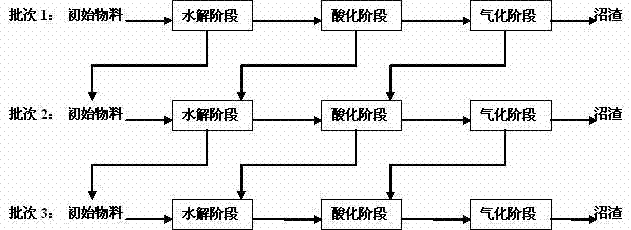

Image

Examples

Embodiment 1

[0026] Take 300L of dewatered sludge from sewage plant A and put it into the first fermentation tank; conduct preliminary solid-liquid separation of 100L of anaerobic granular sludge from the UASB reactor, filter the supernatant, and add the granular sludge to the material; After mixing evenly, the moisture content of the material is 80.8%, the organic matter content is 60%, the C / N ratio is 10.8, and the material adhesion is 45g; seal the feed inlet, set the stirring speed to 12r / min, turn on the ribbon stirring motor switch, and carry out Start the fermentation; 2 days after starting, the temperature of the material measured by the temperature display device is 35°C, and the wet gas flow meter shows that the gas production is 20L, indicating that the material is being hydrolyzed; adjust the stirring speed to 20r / min, and set the stirring motor to turn on for 1 hour / Stop the operation for 1 hour, and after hydrolysis for 4 days, the moisture content of the material is 82.4% a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com