Method for producing 42CrMo steel seamless steel tube

A seamless steel pipe and steel pipe technology, applied in the field of metallurgy, can solve the problems of easy cracking, high cost, and flammability in water quenching, achieve broad application prospects, prevent quenching cracking, and achieve uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment adopts the inventive method to produce 42CrMo steel seamless steel pipe

[0023] Steel pipes with specifications of 198*26mm are produced according to the GB / T3077 standard. The specific chemical composition is shown in Table 1. The production process: electric furnace steelmaking → continuous casting of 220 billets → hot rolling of 180 units → quenching and tempering heat treatment → flaw detection, water pressure, inspection, Package.

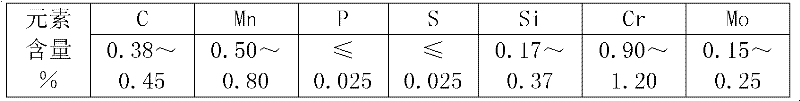

[0024] Chemical composition (weight %) of seamless steel pipe of table 1

[0025]

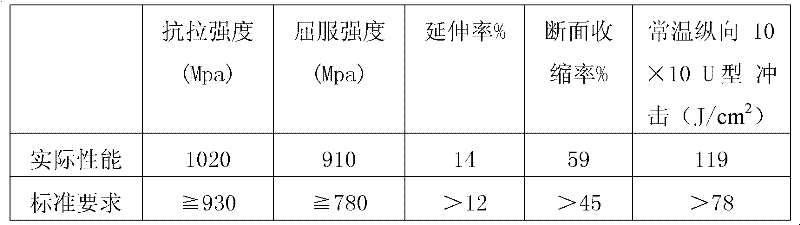

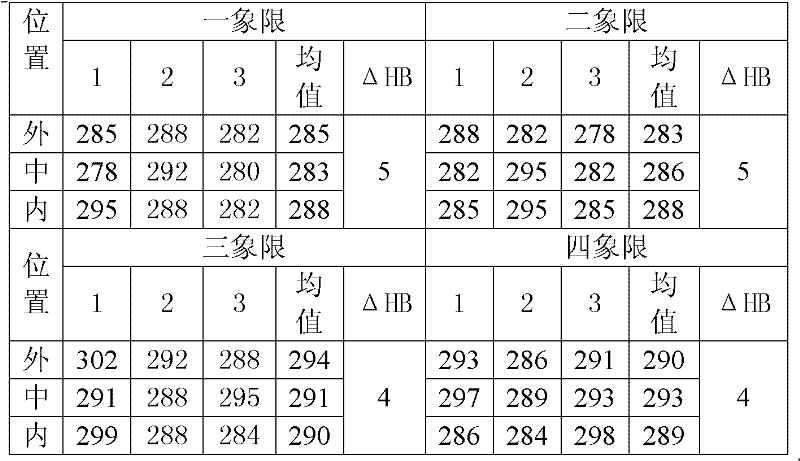

[0026] The hot-rolled steel pipes are produced on a step-by-step continuous heat treatment production line. The quenching heating temperature is 840~860℃. After the quenching furnace is out of the furnace, it is quenched and cooled on the quenching device. The quenching and cooling uses water quenching, and the external spray + internal axial flow method is adopted. When cooling, the internal axial flow starts 5 seconds before the external ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com