Filtering equipment for purifying aquacultural water

A filtration equipment, aquaculture technology, applied in the direction of filtration separation, fixed filter element filter, application, etc., can solve the problem of automatic cleaning of curved screen surface, manual brushing of breeding load and other problems that have not been effectively solved, so as to improve work efficiency and Reliability, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

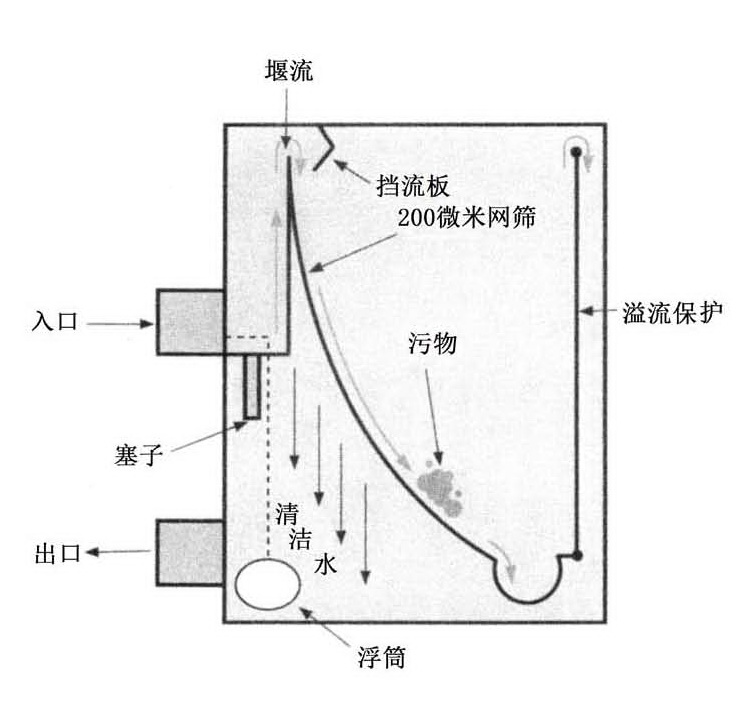

[0026] The main structures and working principles of specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] Figure 5 It is a three-dimensional schematic view of the water filtering device 100 according to the first embodiment of the present invention, and a part of the front shield and screen is cut away to reveal its internal structure. refer to Image 6 and Figure 7 , the whole device is a vertical structure, mainly including a base 110, a frame 120, a screen 130 installed between the base 110 and the frame 120, a water inlet pipeline 140, an outlet pipeline 150, and a drive installed on the frame 120 The device 160 (namely the motor and the reducer), the transmission shaft 170 vertically arranged between the driving device 160 and the base 110, the screen backwashing device 180, and the control unit and other components. Figure 5-7 The specific embodiment shown is an external backwashing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com