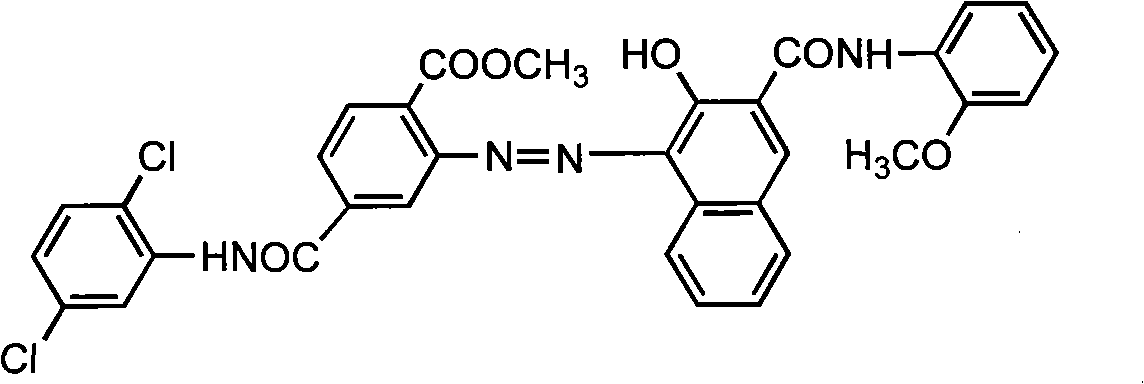

Preparation method of C.I. pigment red 188

A pigment red and pigment technology, applied in the field of preparation of C.I. Pigment Red 188, can solve the problems of difficult diazotization reaction, insoluble, large molecular weight, etc., and achieve the effects of good solvent resistance, easy dispersion and bright color and light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of C.I. Pigment Red 188 is characterized in that: comprising the steps:

[0025] (1) Preparation of diazo solution:

[0026] Dissolve 10.2 grams of 2-carboxymethylcarboxylate-5-(2', 5'-dichlorophenyl)-formamidoaniline in 80 grams of N,N-dimethylacetamide, fully stir to dissolve, and then Add 13 grams of hydrochloric acid with a concentration of 30%, add ice to cool down to 3°C, add 2.2 grams of sodium nitrite to carry out diazotization reaction for 2 hours, use sulfamic acid to remove excess nitrous, and prepare a diazonium solution for later use;

[0027] (2) Dissolution of coupling components:

[0028] Dissolve 6.8 grams of sodium hydroxide and 0.2 grams of ethylenediaminetetraacetic acid in 300 grams of water, raise the temperature to 90°C, add 9 grams of 2-hydroxy-3-naphthoyl-o-methoxyaniline, stir well to dissolve completely , after dissolving and clarifying, lower the temperature to 40°C to obtain an alkaline solution of 2-hydroxy-3-naphth...

Embodiment 2

[0034] The preparation method of C.I. Pigment Red 188 is characterized in that: comprising the steps:

[0035] (1) Preparation of diazo solution:

[0036] Dissolve 10 grams of 2-carboxymethyl-5-(2',5'-dichlorophenyl)-carboxamidoaniline in 60 grams of N-methylpyrrolidone, stir well to dissolve, and then add 10 grams of 30% hydrochloric acid, 1.5 grams of glacial acetic acid with a concentration of 80%, add ice and cool to -15°C, add 2.1 grams of sodium nitrite for diazotization reaction for 2 hours, use sulfamic acid to break the excess nitrous, and prepare Obtain diazo solution for use;

[0037] (2) Dissolution of coupling components:

[0038] Dissolve 6.8 grams of sodium hydroxide and 0.2 grams of ethylenediaminetetraacetic acid in 300 grams of water, raise the temperature to 80°C, add 8.8 grams of 2-hydroxy-3-naphthoyl-o-methoxyaniline, stir well to dissolve completely , after dissolving and clarifying, lower the temperature to 30°C to obtain an alkaline solution of 2-hyd...

Embodiment 3

[0044] The preparation method of C.I. Pigment Red 188 is characterized in that: comprising the steps:

[0045] (1) Preparation of diazo solution:

[0046] Dissolve 10 grams of 2-carboxymethylcarboxylate-5-(2', 5'-dichlorophenyl)-carboxamidoaniline in 100 grams of N, N-dimethyl sulfoxide, fully stir to dissolve, and then Add 15 grams of hydrochloric acid with a concentration of 30%, add ice to cool down to 20°C, add 2.2 grams of sodium nitrite to carry out diazotization reaction for 2 hours, use sulfamic acid to remove excess nitrous, and prepare a diazonium solution for later use;

[0047] (2) Dissolution of coupling components:

[0048] Dissolve 6.8 grams of sodium hydroxide and 0.2 grams of ethylenediaminetetraacetic acid in 300 grams of water, raise the temperature to 100°C, add 9.2 grams of 2-hydroxy-3-naphthoyl-o-methoxyaniline, stir well to dissolve completely , after dissolving and clarifying, lower the temperature to 45°C to obtain an alkaline solution of 2-hydroxy-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com