Six-degree-of-freedom cervical-vertebra grinding parallel robot

A degree of freedom and robot technology, applied in medical science, surgery, etc., can solve the problems of high work intensity, insufficient precision, and excessive radiation for doctors, and achieve the effects of compact structure, improved accuracy and quality, and reduced radiation dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

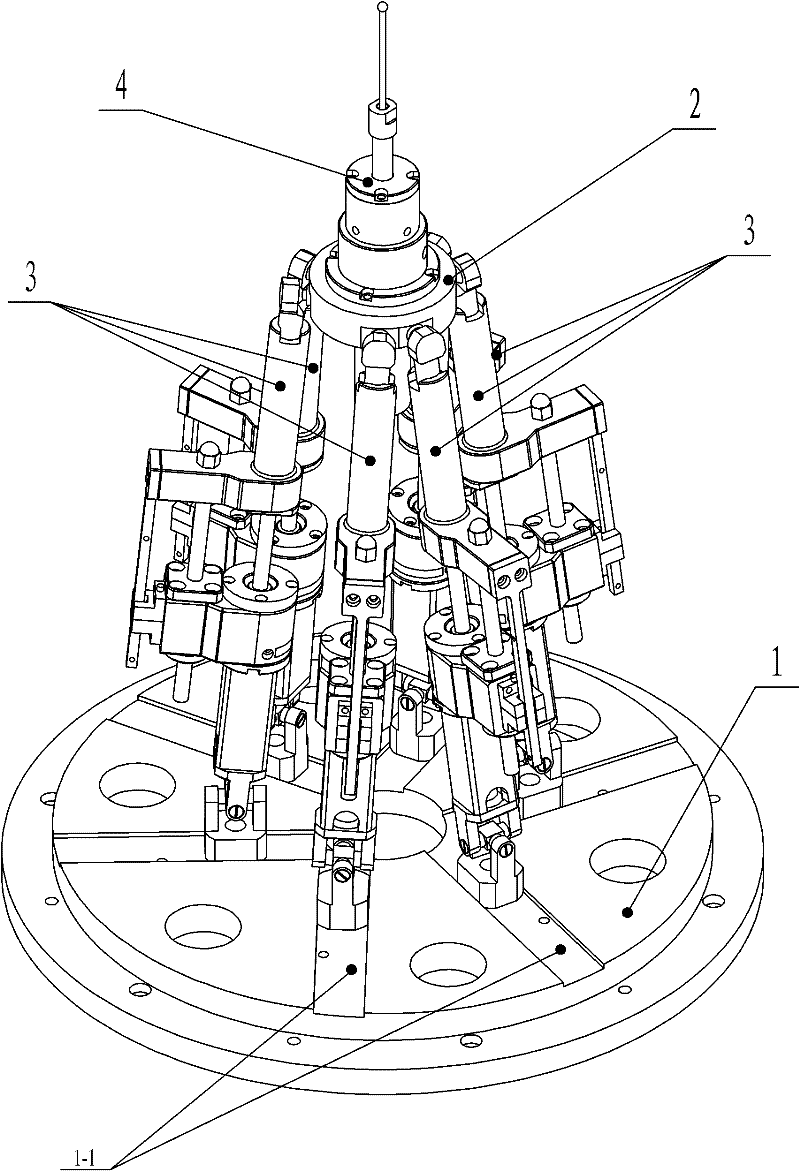

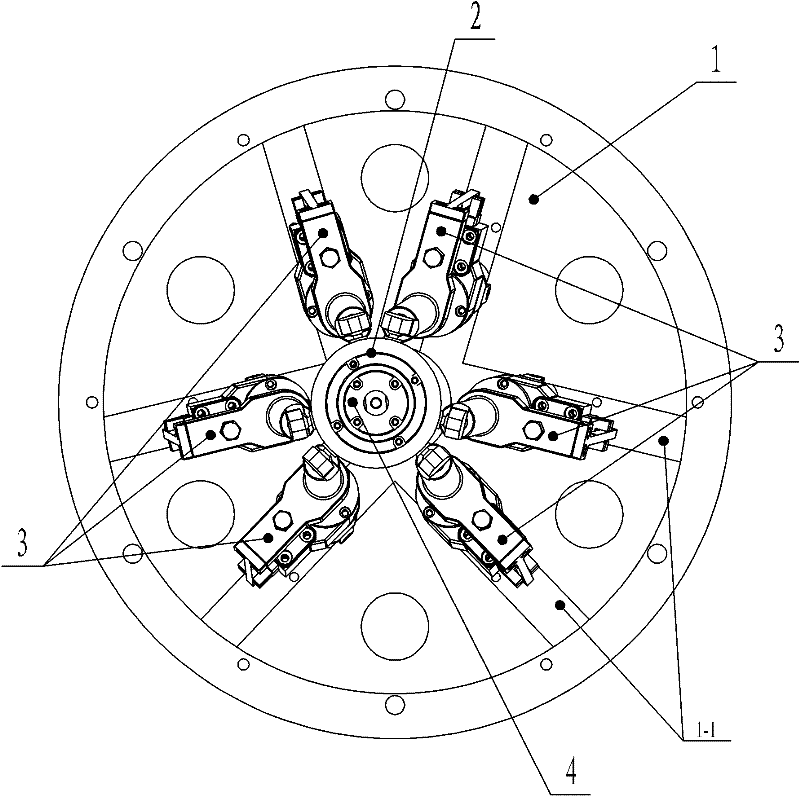

[0007] Specific implementation mode 1: Combination Figure 1-Figure 3 , Figure 5 , Figure 7 or Figure 8 , Picture 9 To explain this embodiment, the six-degree-of-freedom cervical vertebra grinding parallel robot in this embodiment includes a fixed platform 1, a movable platform 2, a grinding drill 4, and three pairs of branch chains. The fixed platform 1 and the movable platform 2 pass through three pairs of branch chains. Each pair of branch chains includes two branch chains 3, and each branch chain 3 includes a ball hinge mechanism 3-1, a ball screw linear drive mechanism and a Hooker hinge mechanism 3-12. The ball hinge mechanism 3-1 is arranged on the ball wire The upper end of the rod linear drive mechanism, the Hooker hinge mechanism 3-12 is arranged at the lower end of the ball screw linear drive mechanism, the ball hinge mechanism 3-1 is connected to the moving platform 2, the Hooker hinge mechanism 3-12 is connected to the fixed platform 1, and the drill 4 includes ...

specific Embodiment approach 2

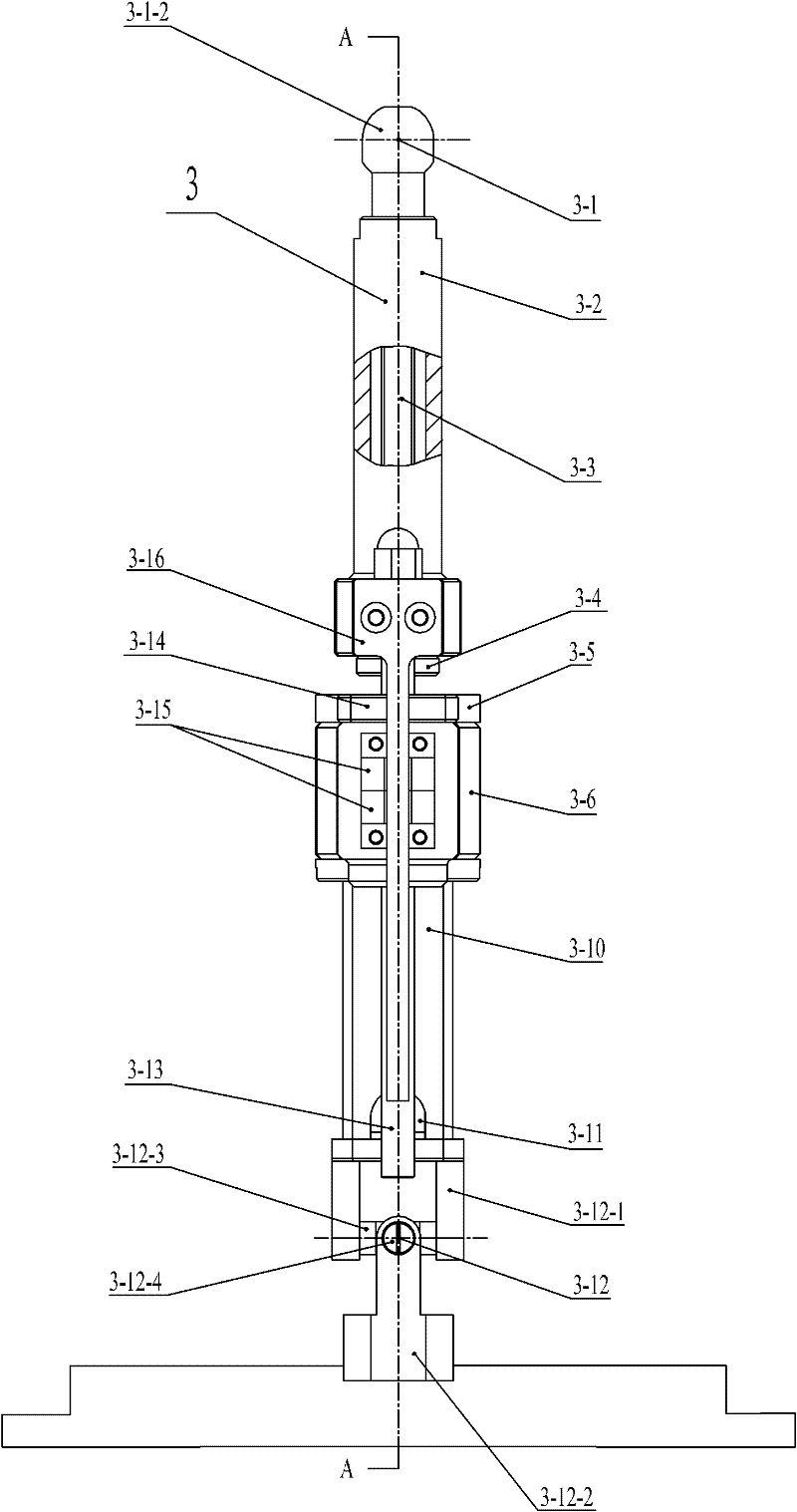

[0009] Specific implementation manner two: combination Figure 3-Figure 6 To explain this embodiment, the ball screw linear drive mechanism of this embodiment includes a branch chain front telescopic rod 3-2, a ball screw 3-3, a ball nut 3-4, a bearing end cover 3-5, and a branch chain motor connector 3. -6, bearing spacer 3-7, lock nut 3-8, branch chain rear rod 3-10, branch chain motor 3-11, Hook hinge 3-12, round guide 3-13, linear ball guide sleeve 3-14 , Two sensors 3-15, positioning block 3-16, two second bearings 3-18, branch chain motor connector 3-6 includes a first connection cavity 3-6-1 and parallel to the first connection cavity The second connecting cavity 3-6-2 offset a certain distance, one end of the ball screw 3-3 is inserted in the front telescopic rod 3-2 of the branch chain, and one end of the ball screw 3-3 is installed in the ball nut 3-4 , The ball nut 3-4 is fixedly connected to the front telescopic rod 3-2 of the branch chain, the other end of the ball...

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 5 To explain this embodiment, the ball screw linear drive mechanism of this embodiment also includes a top screw cover 3-9 and a top screw 3-17. The branch chain motor connector 3-6 is provided with a top screw hole, and the top screw cover 3- 9 is set on the top screw hole, and the input end of the ball screw 3-3 and the output shaft end of the branch chain motor 3-11 are connected through the top screw 3-17. This arrangement facilitates the installation of the top wire 3-18, and facilitates the replacement and tightening of the top wire 3-18. Other components and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com