Titanium welded pipe and stainless steel welded pipe forming roller and surface treatment method thereof

A stainless steel and titanium welded pipe technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of short service life of rolls, can not meet the needs of use, easy to wear rolls, etc., to improve surface hardness and wear resistance. , to meet the effect of efficient continuous production and rigid demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

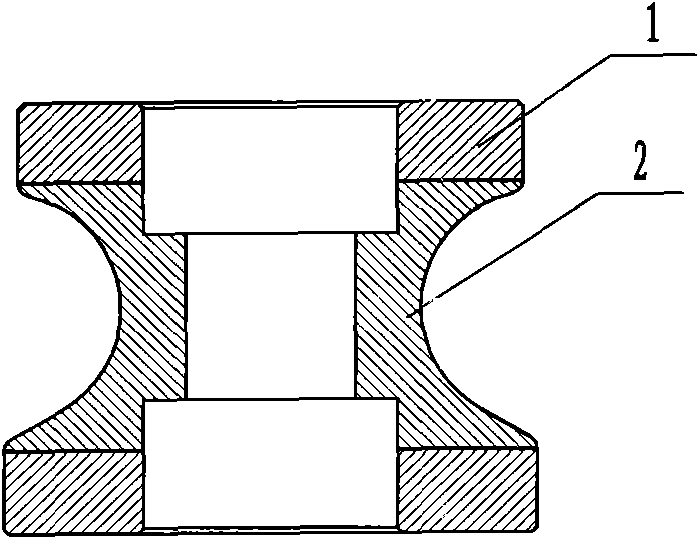

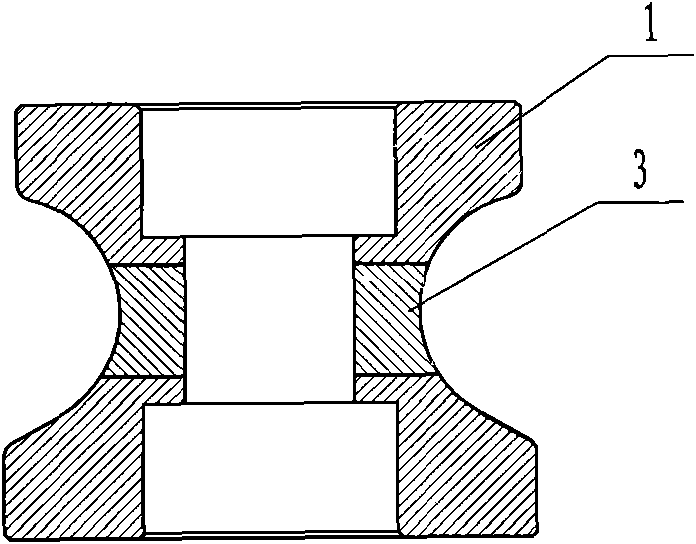

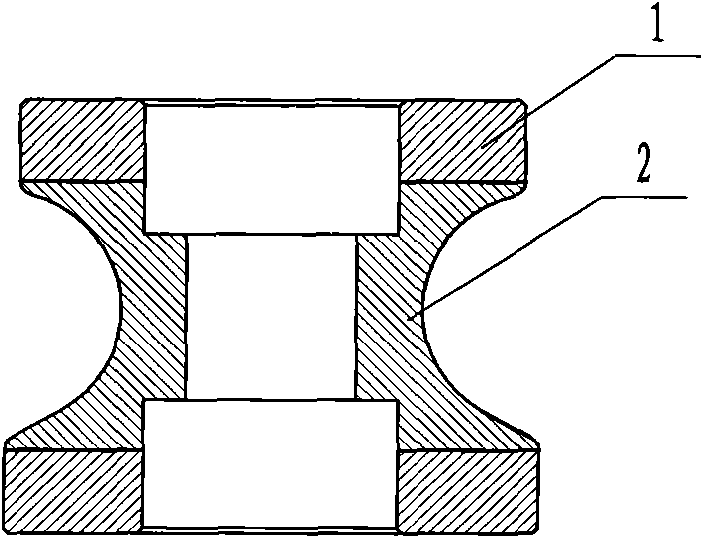

[0019] figure 1 and figure 2 Shown are the titanium welded pipe and stainless steel welded pipe forming rolls of the present invention, including precision forming roll pairs and sizing roll pairs. The base material 1 is made of alloy tool steel material which is wear-resistant and suitable for coating, such as alloy tool steel H13, that is, 4Cr5MoSiV1 alloy. In the roll forming part 2 or tumor accumulation part 3, the combination of ion nitriding and diamond-like film plating process is used for surface coating treatment, so as to form a composite coating of nitriding layer and diamond-like film. The forming roll achieves a superhard and super smooth surface state, the mold surface hardness is ≥ 23GPa, and the friction coefficient is less than 0.20. The roll surface is incompatible with titanium and stainless steel, which solves the problem of scratches on the welded pipe surface and increases the service life by 2 ~3 times. The roll is processed and shaped by an optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap