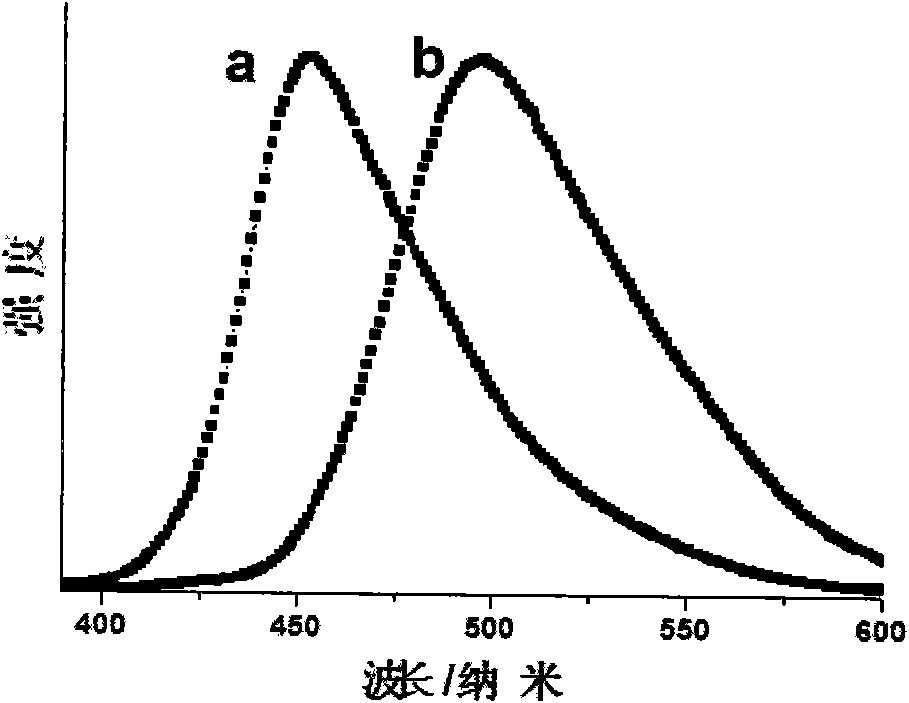

Piezofluorescent color changing material with intercalation structure and preparation method thereof

A color-changing material and pressure-induced technology, applied in the direction of color-changing fluorescent materials, luminescent materials, chemical instruments and methods, etc., to achieve the effect of expanding the application range and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Weigh 1.282g Mg(NO 3 ) 2 ·6H 2 O, 0.938g Al(NO 3 ) 3 9H 2 O and 5.438g fluorescent whitening agent 357 were dissolved in 200ml to remove CO 2 1. In deionized water, stir and dissolve to obtain solution A;

[0024] 2. Dissolve another 0.6g NaOH in 100ml to remove CO 2 , deionized water to obtain solution B;

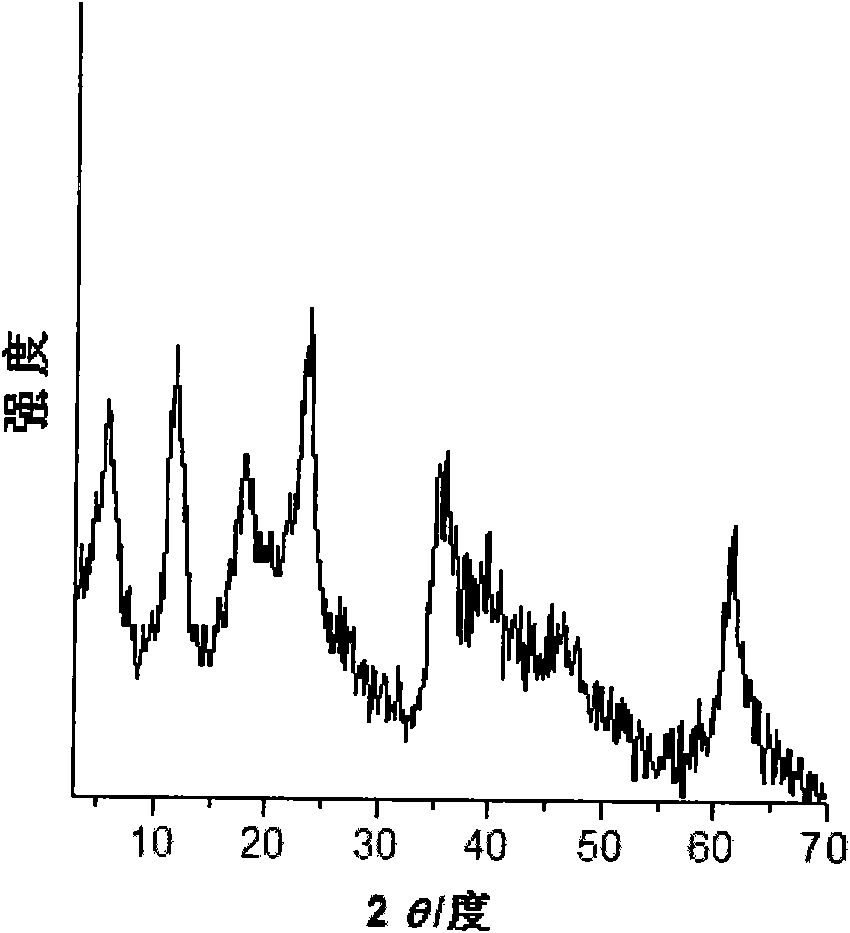

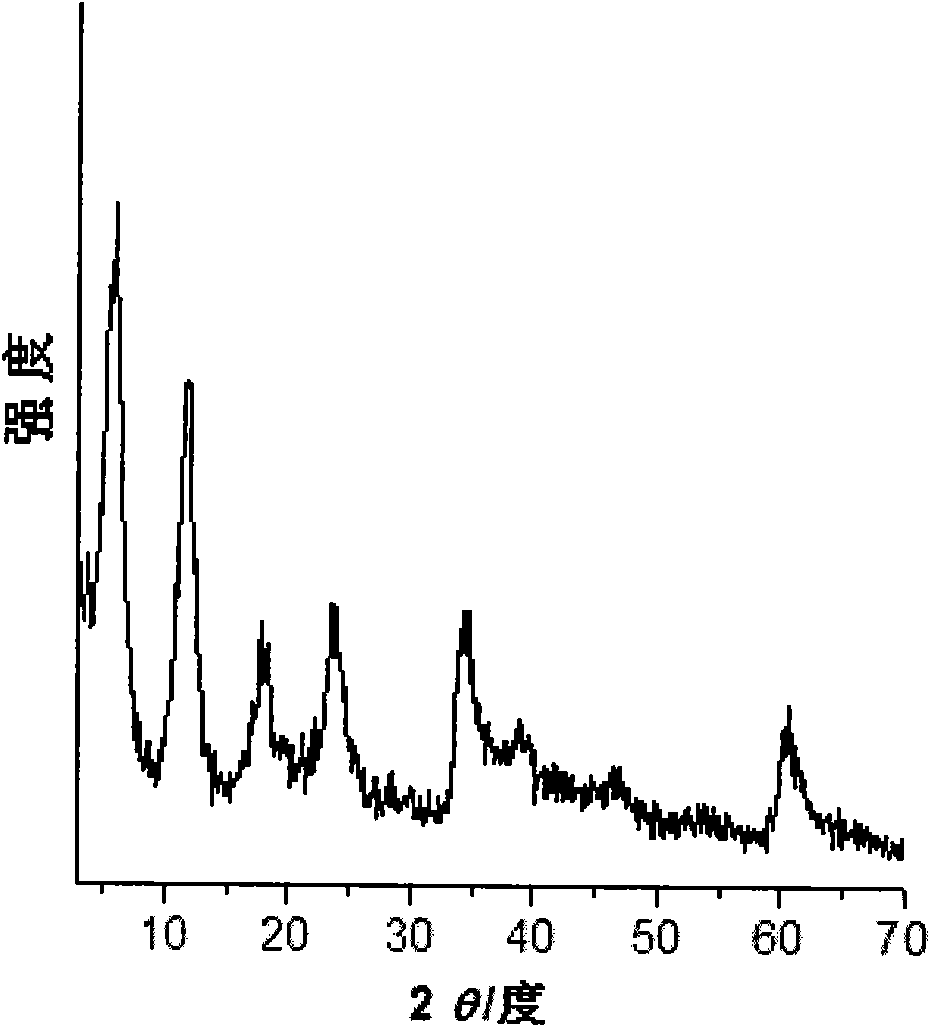

[0025] 3. Using the co-precipitation method, pass solution B through a constant pressure funnel, and add it dropwise to the four-necked bottle containing solution A under the condition of nitrogen protection. After the dropwise addition, adjust the pH to 8.0 with NaOH, and put the four-necked bottle Put it in a water bath at 70°C and react for 18h under the condition of nitrogen protection. 2 , fully washed with deionized water and centrifuged for 5 times until the washing liquid is colorless; vacuum-dried at 50°C for 24 hours to obtain a yellow-white powder, and after grinding to obtain the fluorescent whitening agent 357 anion-intercalated hydrotalcite ...

Embodiment 2

[0028] 1. Weigh 2.975g Zn(NO 3 ) 2 ·6H 2 O, 1.876g Al(NO 3 ) 3 9H 2 O and 10.875g fluorescent whitening agent 357 were dissolved in 150ml to remove CO 2 1. In deionized water, stir and dissolve to obtain solution A;

[0029] 2. Dissolve another 1.2g NaOH in 100ml to remove CO 2 , deionized water to obtain solution B;

[0030] 3. Using the co-precipitation method, pass solution B through a constant pressure funnel, and add dropwise to the four-necked bottle containing solution A under the condition of nitrogen protection. After the dropwise addition, adjust the pH to 10.0 with NaOH, and put the four-necked bottle Put it in a water bath at 80°C and react for 20h under the condition of nitrogen protection. 2 1. Fully wash with deionized water and centrifuge for 6 times until the washing liquid is colorless; vacuum dry at 70°C for 20 hours to obtain a yellow-white powder, and after grinding, obtain the fluorescent whitening agent 357 anion-intercalated hydrotalcite. Materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spectroscopy | aaaaa | aaaaa |

| spectroscopy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com