Process for producing medium and high carbon steel in sheet billet continuous casting and rolling production

A thin slab continuous casting, medium and high carbon technology, used in metal rolling and other directions, can solve the problems of inactive mold, small mold hot melt, poor melting conditions of mold slag, etc., to avoid internal quality defects and surface defects. Quality defects, surface quality and good size and shape control, the effect of improving product quality and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through embodiment.

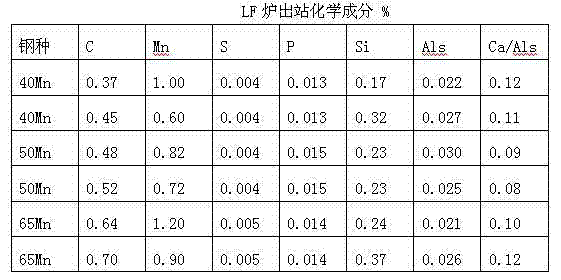

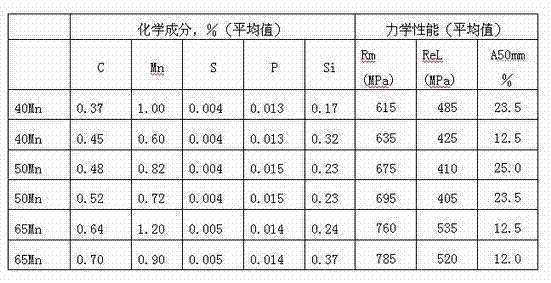

[0023] In the embodiment, the process flow of thin slab continuous casting and rolling to produce medium and high carbon steel is: blast furnace molten iron→converter operation→LF refining→thin slab continuous casting→heating→rolling→cooling→coiling→finished product.

[0024] Converter 150t, LF refining 150t, thin slab continuous casting width 12500mm thick 70mm, heating adopts 230m tunnel type heating furnace, cooling is laminar flow cooling, and produces steel grades of 40Mn, 50Mn, 65Mn.

[0025] Concrete operation steps and each process technological parameter control are as follows:

[0026] (1) Converter operation process

[0027] a. Molten iron temperature 1350℃, S=0.005%, P=0.12%;

[0028] b. The blowing process takes dephosphorization as the main goal, requires the whole process of slag removal, and the furnace temperature rises steadily;

[0029] c. The position of the final pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com