Carbon and fiber composite material artificial foot molding technology

A composite material and molding process technology, applied in the field of prosthetic foot molding, can solve the problems of parts prone to delamination, porosity, user injury, prosthetic foot failure, etc., and achieves strong designability, low porosity, and fatigue resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

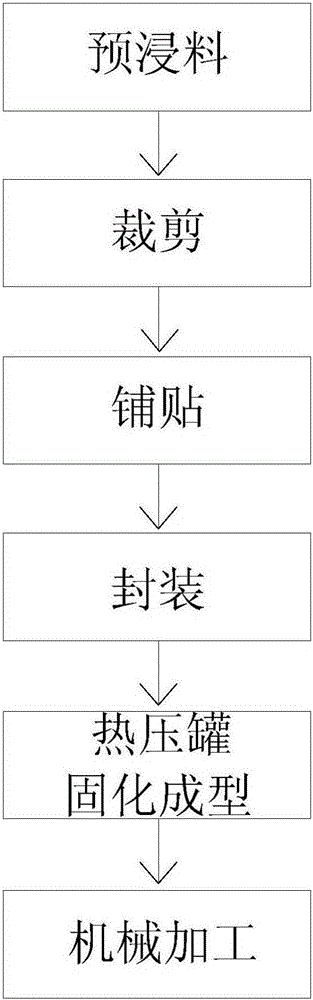

[0035] Such as figure 1 and figure 2 As shown, the carbon fiber composite prosthetic foot molding process in the present embodiment comprises the following steps:

[0036] (1) Prepreg

[0037] Prepregs include unidirectional carbon fiber prepregs and 3K carbon fiber woven cloth prepregs; the carbon fiber content of unidirectional carbon fiber prepregs is 190g / m 2 , the epoxy resin content is 34%; the carbon fiber content of the 3K carbon fiber woven cloth prepreg is 200g / m 2 , the epoxy resin content is 25%.

[0038] (2) cropping

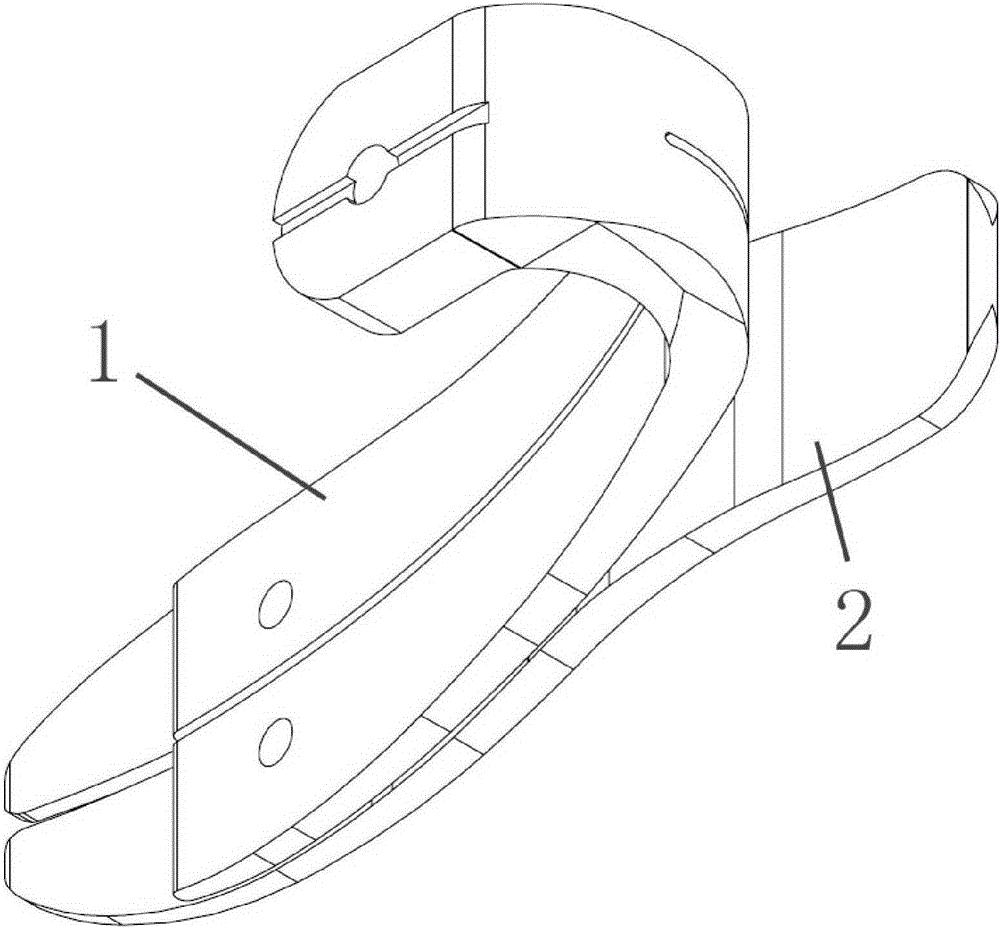

[0039] According to the layup design of the part, the prepreg is cut out to the shape and number of layers required for the prosthetic foot, and each layer of prepreg is numbered in sequence; the prosthetic foot here includes the upper foot plate 1 and the lower foot plate 2.

[0040] (3) Paving

[0041] After the release agent is evenly coated on the mold and dried, the prepreg is laid layer by layer according to the laying order to form a b...

Embodiment 2

[0054] Such as figure 1 and figure 2 As shown, the carbon fiber composite prosthetic foot molding process in the present embodiment comprises the following steps:

[0055] (1) Prepreg

[0056] Prepregs include unidirectional carbon fiber prepregs and 3K carbon fiber woven cloth prepregs; the carbon fiber content of unidirectional carbon fiber prepregs is 224g / m 2 , the epoxy resin content is 42%; the carbon fiber content of the 3K carbon fiber woven cloth prepreg is 220g / m 2 , the epoxy resin content is 45%.

[0057] (2) cropping

[0058] According to the layup design of the part, the prepreg is cut out to the shape and number of layers required for the prosthetic foot, and each layer of prepreg is numbered in sequence; the prosthetic foot here includes the upper foot plate 1 and the lower foot plate 2.

[0059](3) Paving

[0060] After the release agent is evenly coated on the mold and dried, the prepreg is laid layer by layer according to the laying order to form a bl...

Embodiment 3

[0073] Such as figure 1 and figure 2 As shown, the carbon fiber composite prosthetic foot molding process in the present embodiment comprises the following steps:

[0074] (1) Prepreg

[0075] Prepregs include unidirectional carbon fiber prepregs and 3K carbon fiber woven cloth prepregs; the carbon fiber content of unidirectional carbon fiber prepregs is 207g / m 2 , the epoxy resin content is 38%; the carbon fiber content of the 3K carbon fiber woven cloth prepreg is 210g / m 2 , the epoxy resin content is 35%.

[0076] (2) cropping

[0077] According to the layup design of the part, the prepreg is cut out to the shape and number of layers required for the prosthetic foot, and each layer of prepreg is numbered in sequence; the prosthetic foot here includes the upper foot plate 1 and the lower foot plate 2.

[0078] (3) Paving

[0079] After the release agent is evenly coated on the mold and dried, the prepreg is laid layer by layer according to the laying order to form a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com