Light source module and preparation method thereof

A light source module, light emitting diode technology, applied in the direction of light source, electric light source, point light source, etc., can solve the problems of wire breakage, unprotected wire bonding, difficult mounting, etc., and reduce the probability of wire breakage , stable performance, easy to combine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

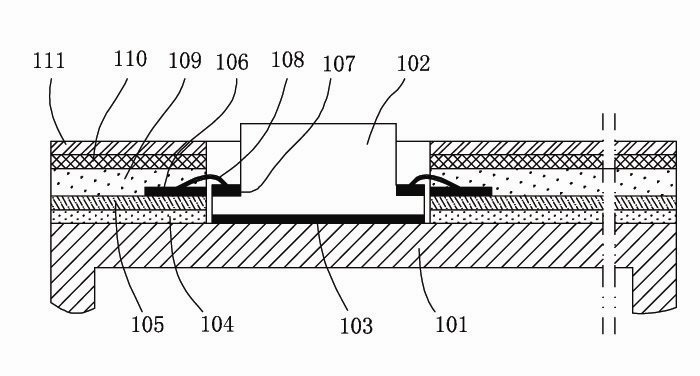

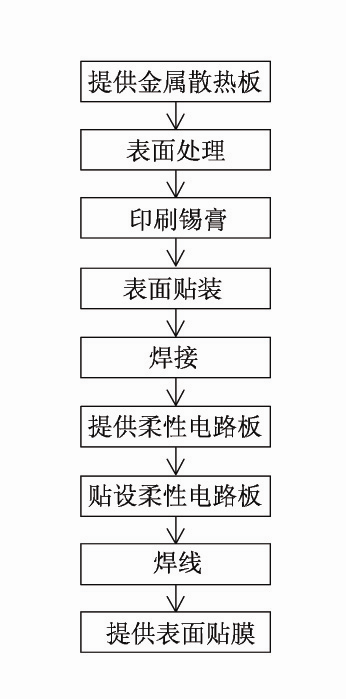

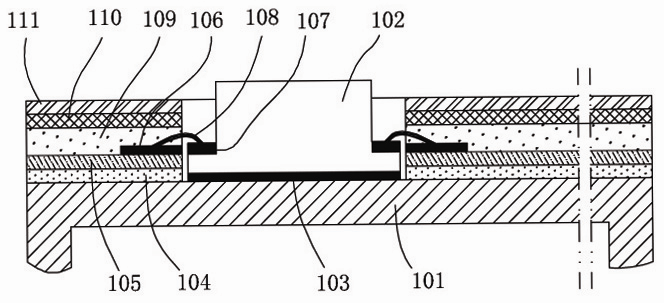

[0028] refer to figure 1 , the first embodiment of the present invention is a light source module, including a light emitting diode 102, and also includes a metal heat sink 101, the light emitting diode 102 is directly arranged on the metal heat sink 101 by SMT; the light source module also includes a flexible circuit board 105, the front side of the flexible circuit board 105 has a printed circuit 106, and the back side of the flexible circuit board 105 is attached to the metal heat sink 101 by PAS glue, that is figure 1The film layer shown in 104 in; the flexible circuit board 105 has a through hole, and the light emitting diode 102 is arranged in the through hole; One of the differences of the light-emitting diodes is that the connection end between the internal circuit and the external circuit is the electrode to be welded instead of the pin, and the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com