Grate firing biomass boiler

A biomass boiler and furnace technology, which is applied in the treatment of combustion products, steam boilers, combustion methods, etc., can solve the problems of easy accumulation of ash on the heat exchange surface of the boiler, the failure of the equipment to work normally, and the inability to achieve the designed output. Thermal effect, increase workload, ensure the effect of output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

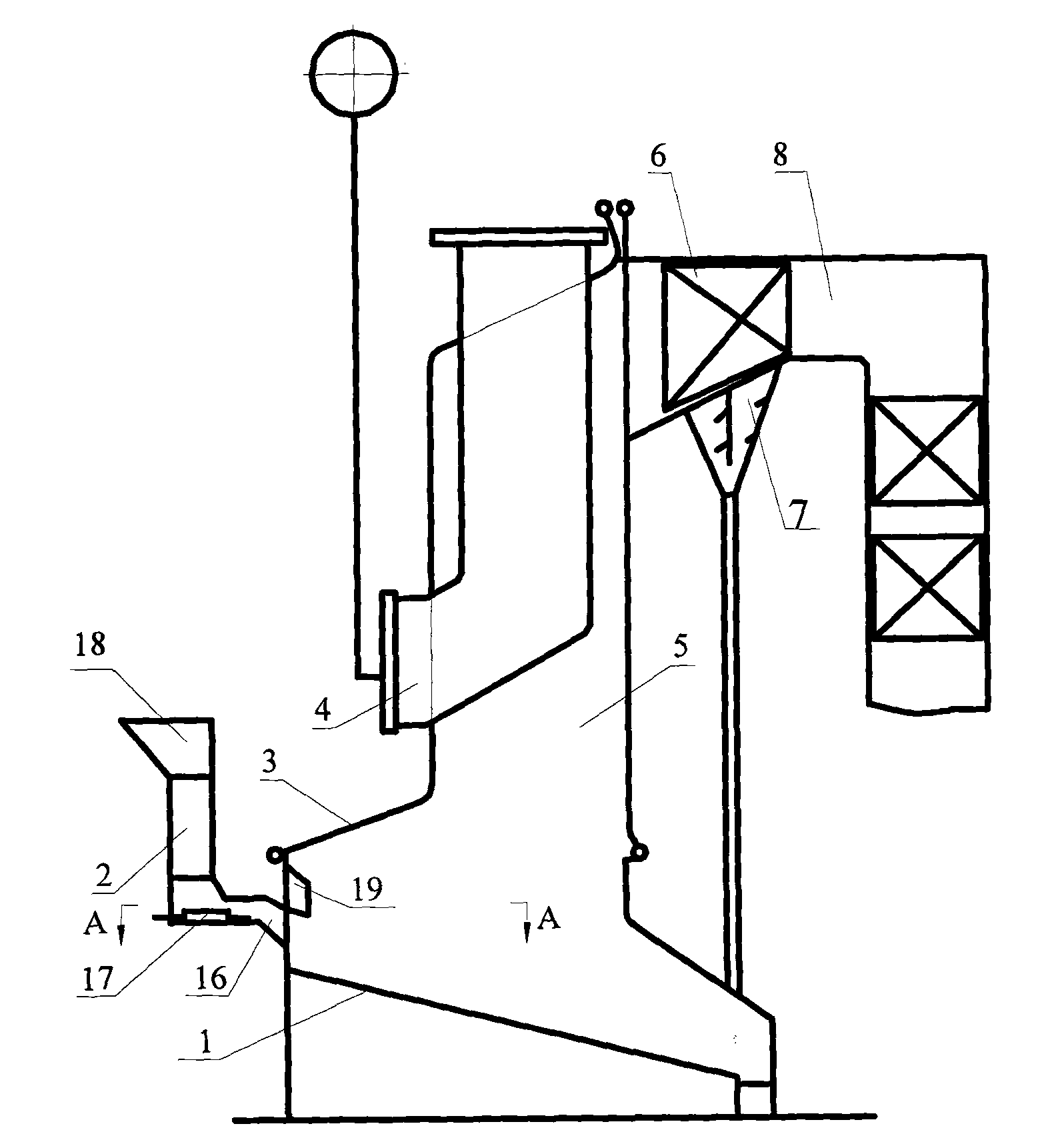

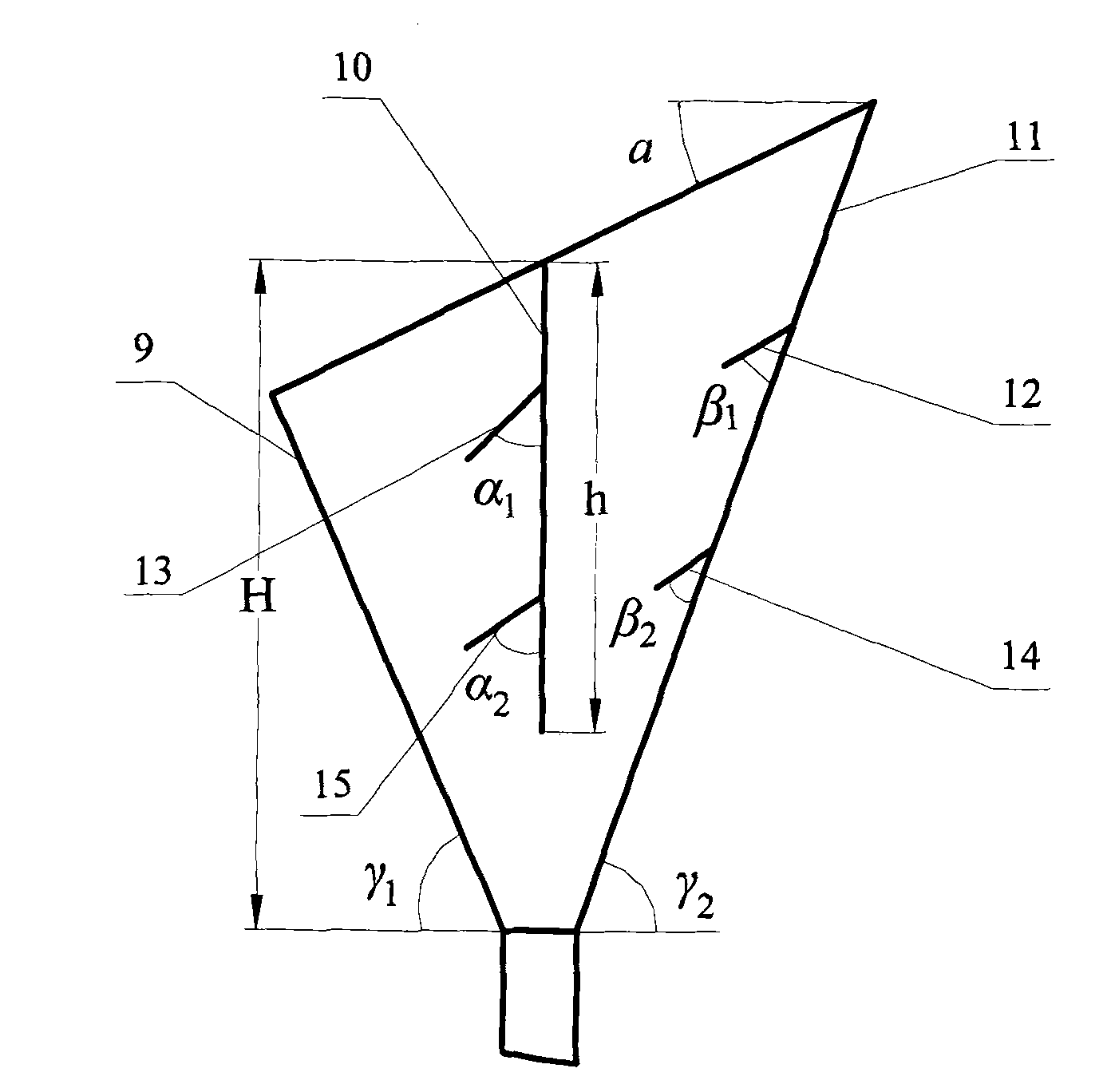

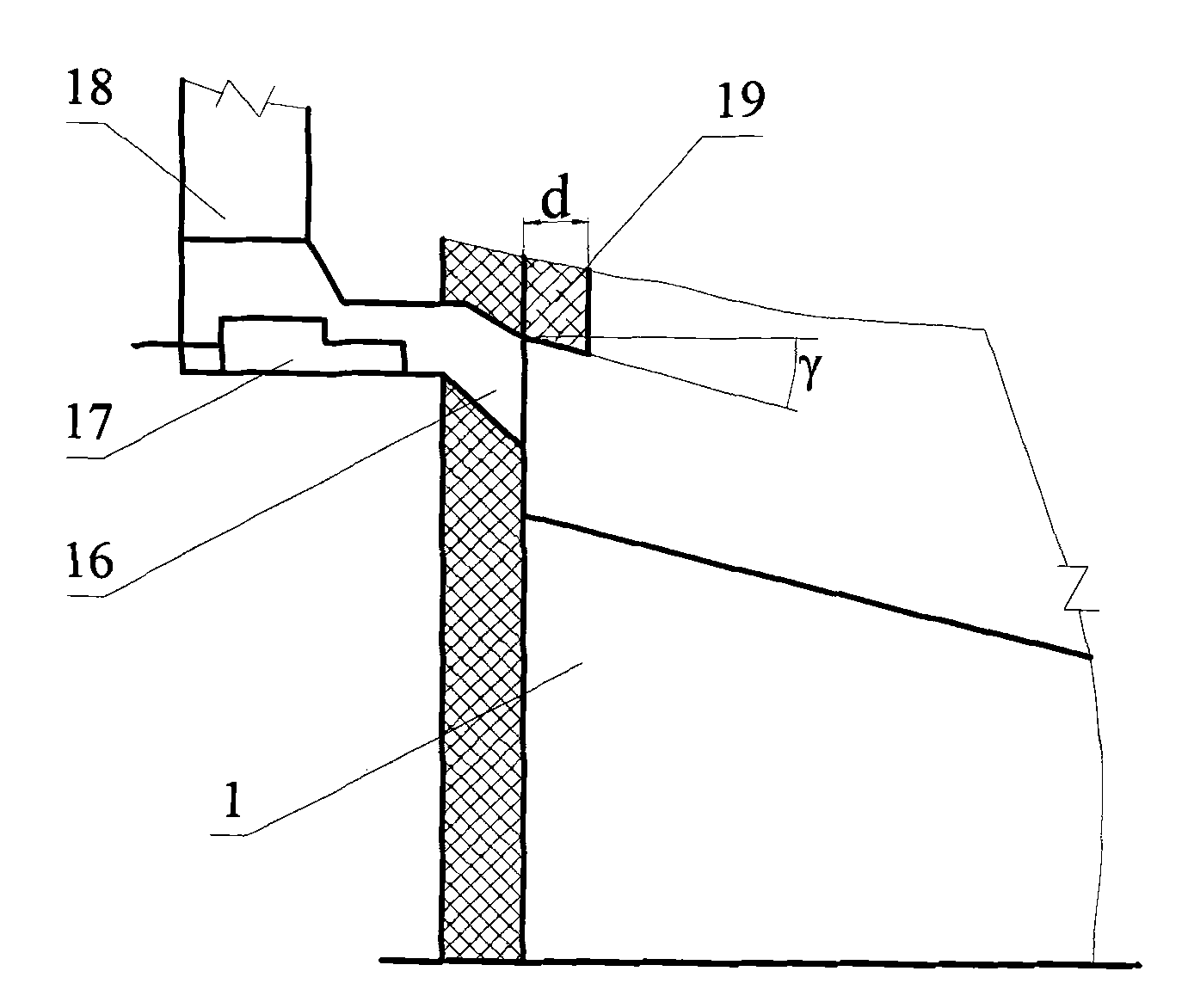

[0019] figure 1 It is a schematic diagram of the structure and principle of the layer-fired biomass boiler involved in the present invention. The present invention includes a fire grate 1, a feeding device 2, a boiler furnace 5, a horizontal flue 8 and a panel water wall 4. The fire grate 1 is arranged under the furnace 5 , the panel water-cooled wall 4 is arranged in the boiler furnace 5 , and the superheater 6 is arranged in the horizontal flue 8 . Described feeding device 2 contains feeding hopper 18, feed pusher 17 and blanking channel 16 (as image 3 shown). Fire grate 1 can select chain fire grate or reciprocating fire grate according to the different types of fuel.

[0020] Biomass fuel, such as wood blocks, etc., is fed by the feeding hopper 18 of the feeding device 2. Under the promotion of the pusher 17, it enters the furnace 5 along the blanking channel 16 arranged under the front arch 3 of the furnace. The designed thickness is distributed on the grate 1 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com