Vao productivity suite

A productivity, facility technology, applied in the field of semiconductor fabrication facility visualization systems, semiconductor fabrication facility productivity systems, and monitoring semiconductor fabrication facility operations, to address issues such as increasing cycle time control complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

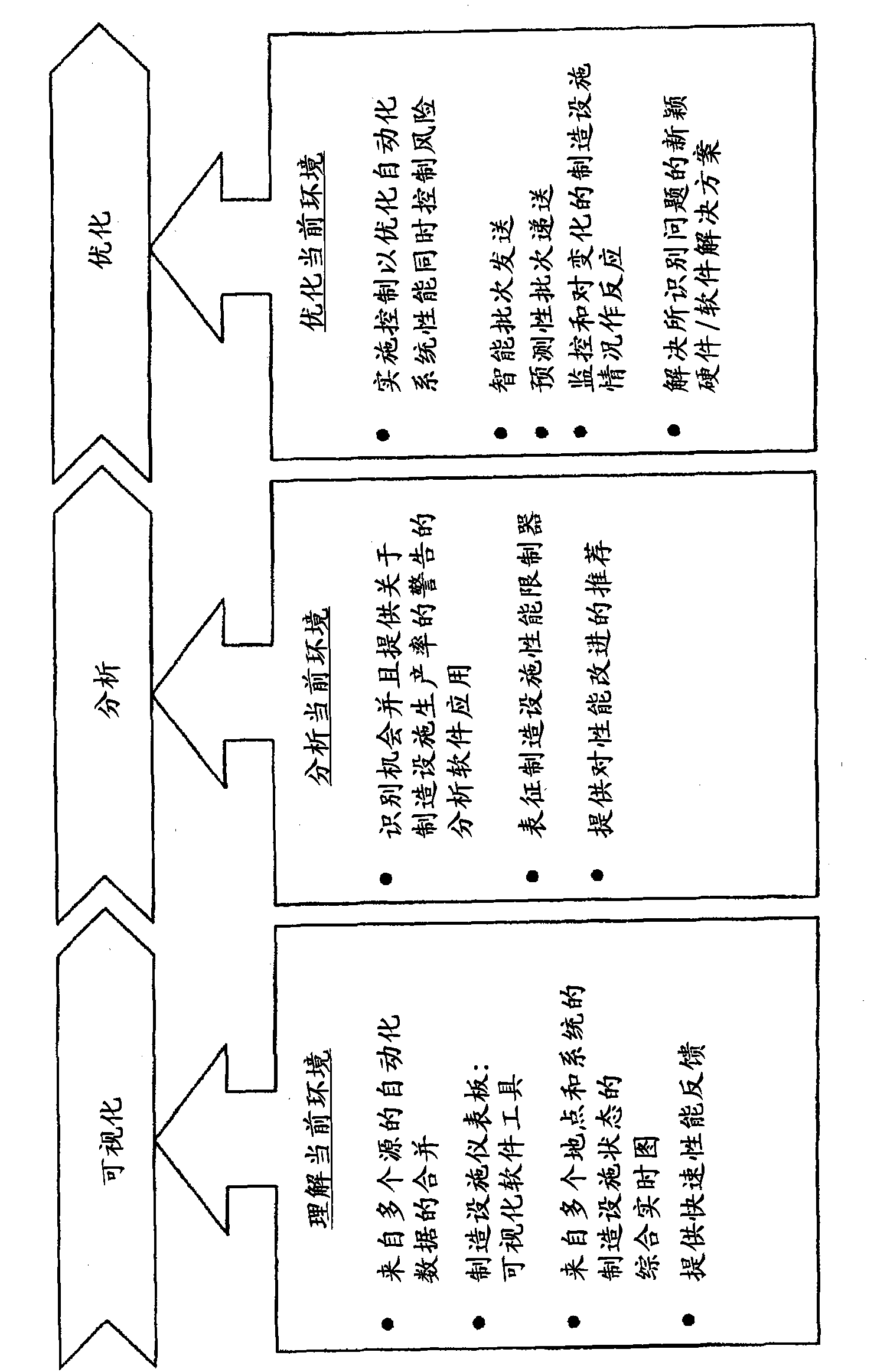

AI Technical Summary

Problems solved by technology

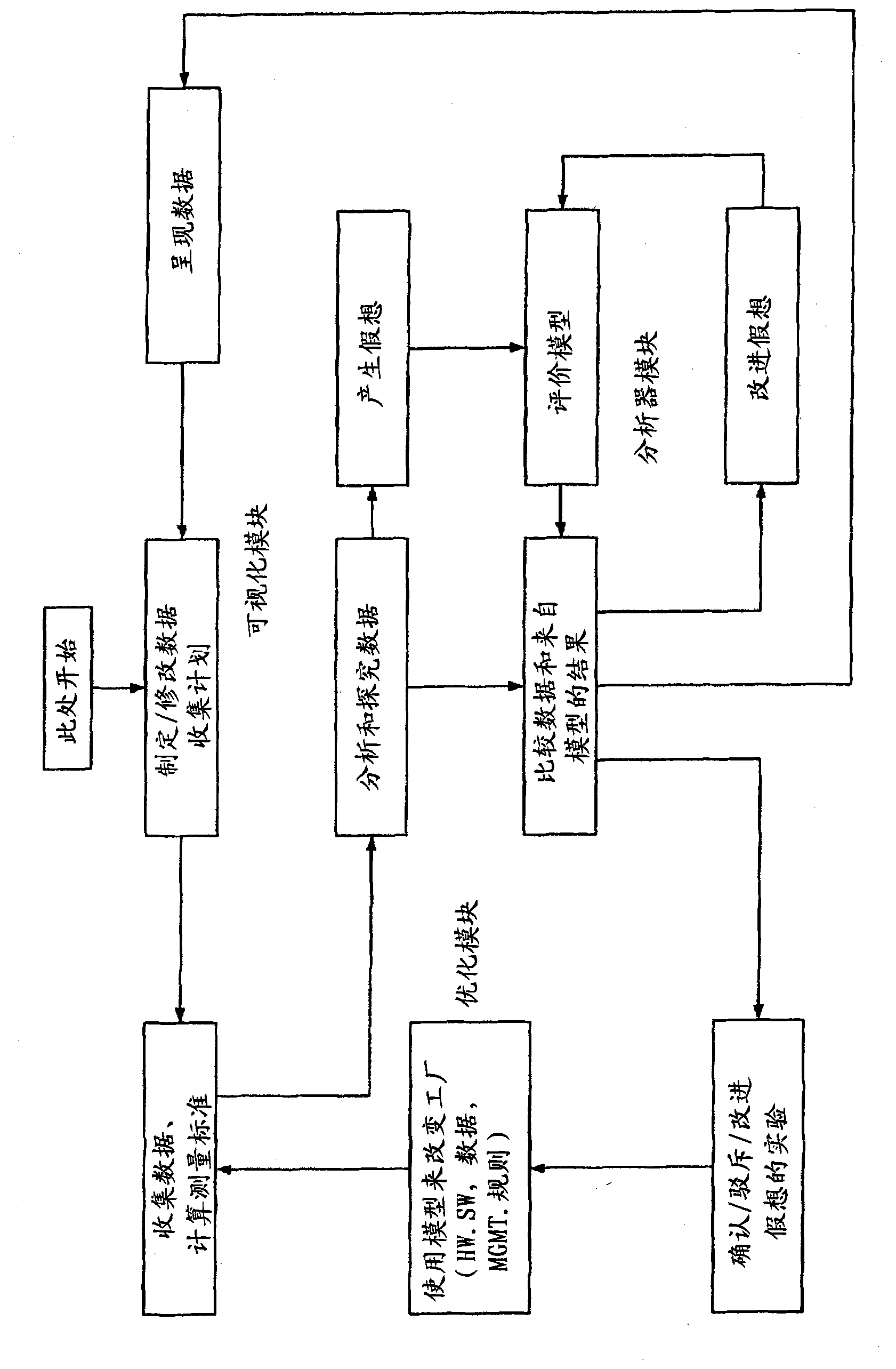

Method used

Image

Examples

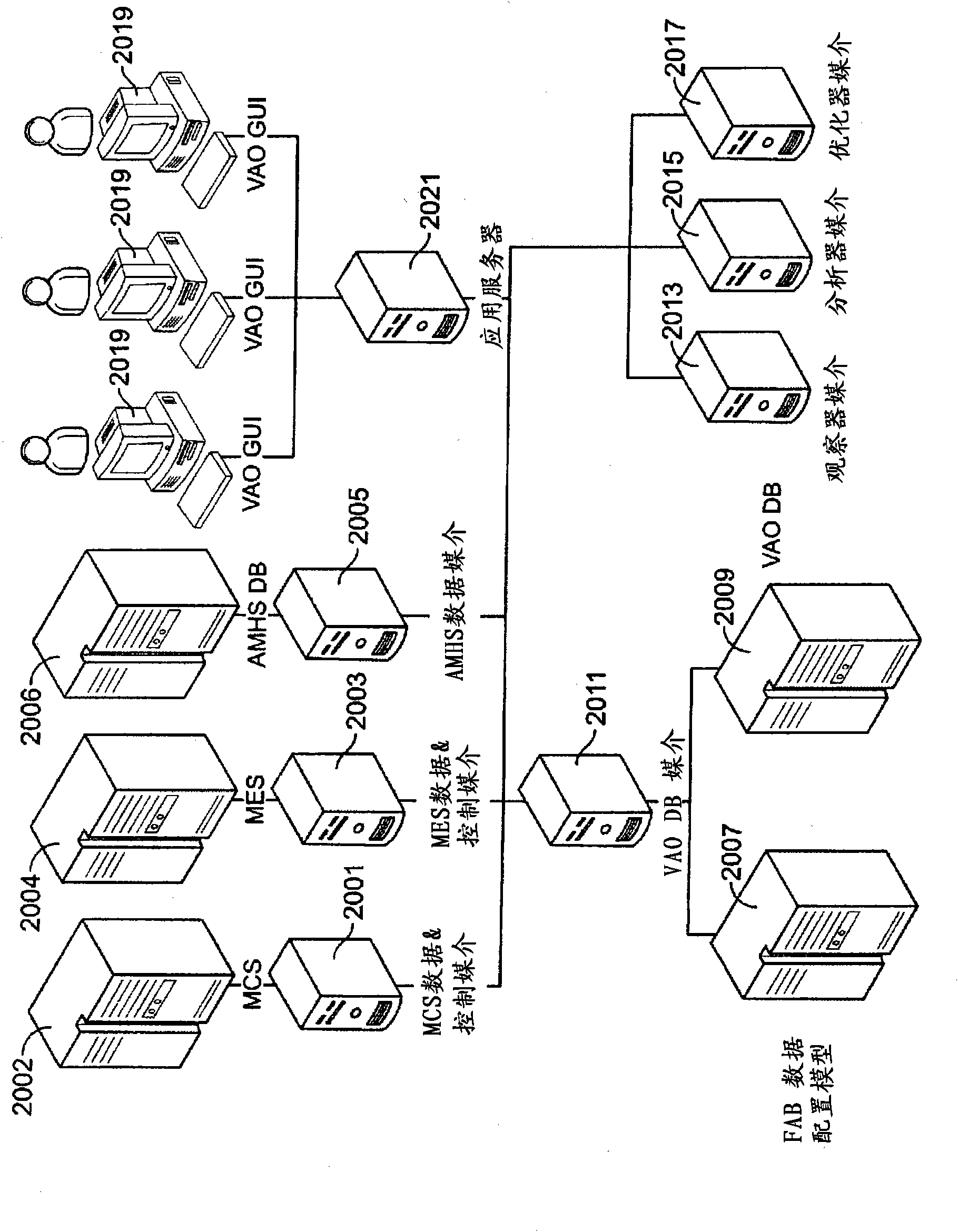

Embodiment Construction

[0021] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. It will be evident, however, that one skilled in the art may practice the present invention without some or all of these specific details. In other instances, well known process operations have not been described in detail in order not to unnecessarily obscure the present invention.

[0022] Abbreviation definition

[0023] ●AGV: automated guided vehicle

[0024] ●AMHS: Automatic Material Handling System

[0025] ● BKM: Best Known Method - Industry Best Practice

[0026] ●DB: database

[0027] ●EDA: Electronic Design Automation

[0028] • EFEM: Equipment Front End Module - In automated semiconductor equipment, this tool section moves wafers between transports on load ports towards load and / or process chambers.

[0029] • FDIM: Plant Data Integration Manager - a product that reconciles equipment data with plant data systems. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com