Permanent magnet for motor, and method for manufacturing the permanent magnet for motor

一种永久磁铁、制造方法的技术,应用在电动机用永久磁铁及电动机用永久磁铁的制造领域,能够解决矫顽力下降、下降等问题,达到减小涡电流、简化制造工序的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

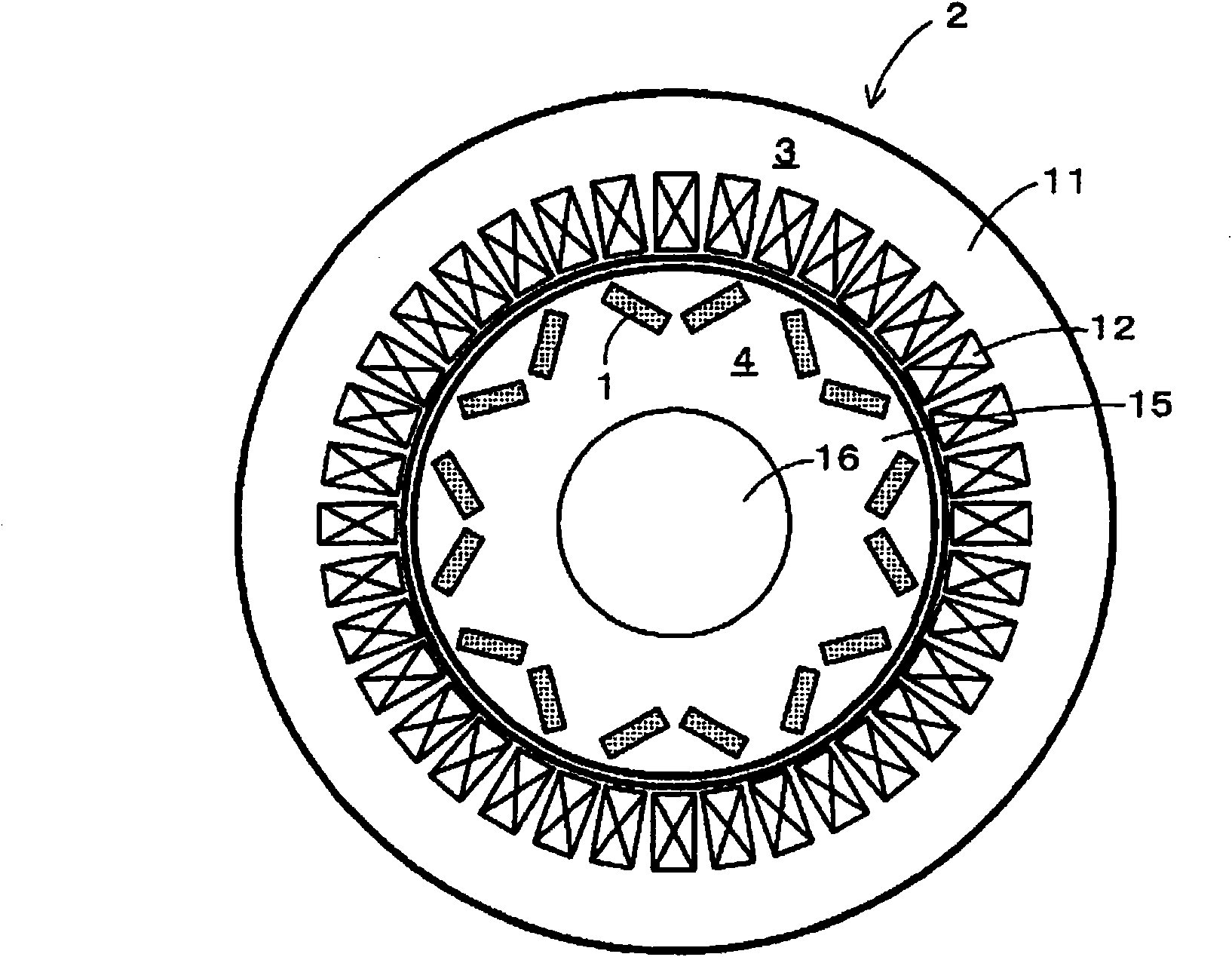

[0089] Hereinafter, a specific embodiment of the permanent magnet for electric motor and the method for manufacturing the permanent magnet for electric motor according to the present invention will be described in detail with reference to the drawings. First, based on figure 1 The structure of the permanent magnet motor 2 in which the permanent magnet 1 of this embodiment is embedded is demonstrated. figure 1 It is a figure which shows the internal structure of the permanent magnet motor 2 which concerns on embodiment of this invention.

[0090] Such as figure 1 As shown, the permanent magnet motor 2 is basically composed of a stator 3 and a rotor 4 rotatably arranged inside the stator 3 .

[0091] First, the stator 3 will be described. The stator 3 is composed of a stator core 11 and a plurality of stator coils 12 wound around the stator core 11 . In addition, a predetermined number of stator coils 12 are arranged at equal intervals on the inner peripheral surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com