Process for producing negative pressure foamed refrigerator

A production process and refrigerator technology, applied in the field of refrigerator foaming, can solve the problems of high foam density, increased flow resistance, and poor thermal insulation performance of refrigerators, and achieve the effects of high foam strength, small flow resistance, and reduced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

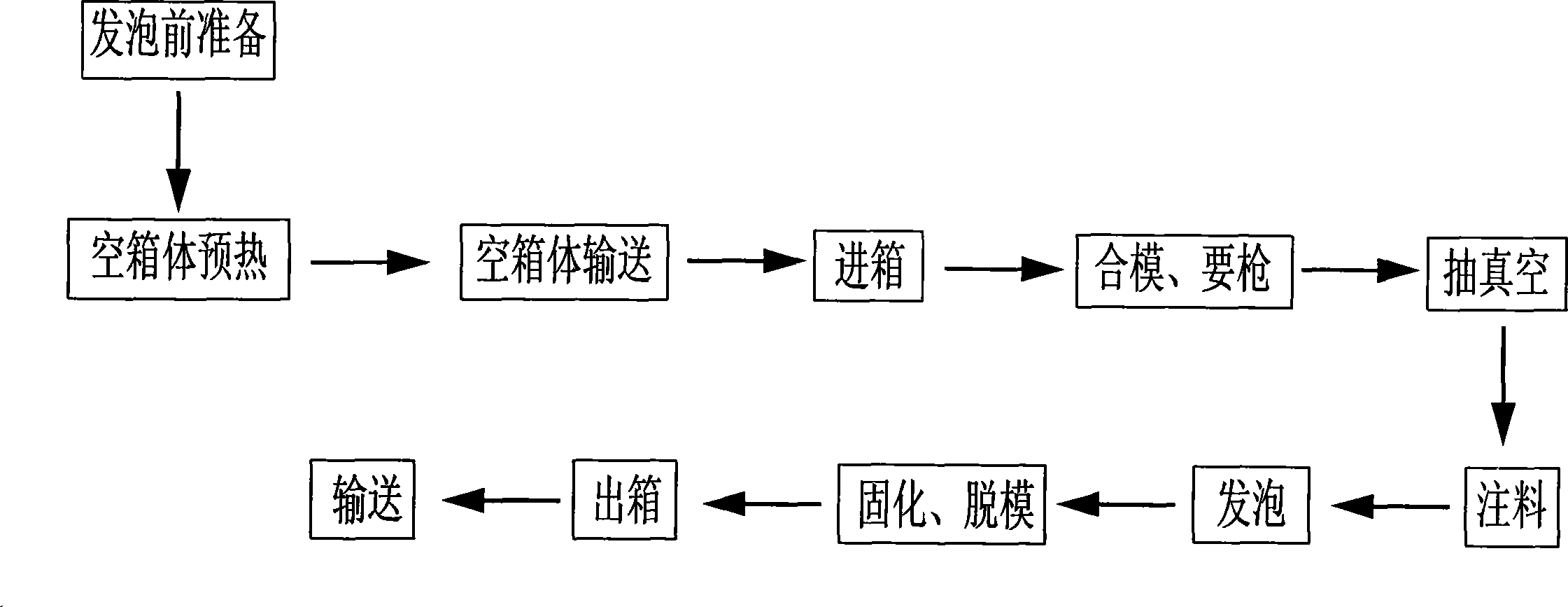

[0025] Embodiment: The production process of the negative pressure foaming refrigerator of the present invention is carried out according to the following steps:

[0026] a. Place the refrigerator box in a sealed system;

[0027] b. Vacuum the cavity of the box body before injection to make it in a negative pressure state;

[0028] c. Inject material into the box cavity, and the material liquid is foamed, filled, and solidified to form a foamed box.

[0029] The vacuuming step is that the vacuum degree of the box cavity is in the range of 0 to -0.08Mpa;

[0030] The injection step is to inject a feed liquid composed of isocyanate and combined polyether in parts by weight of 1.1 to 1.3:1 into the cavity of the box body. The combined polyether contains a foaming agent, and the foaming agent is added The weight percent in ether is 9~23%;

[0031] The foaming agent is one or a combination of cyclopentane, isopentane, 245fa, 365mfc, and 134a.

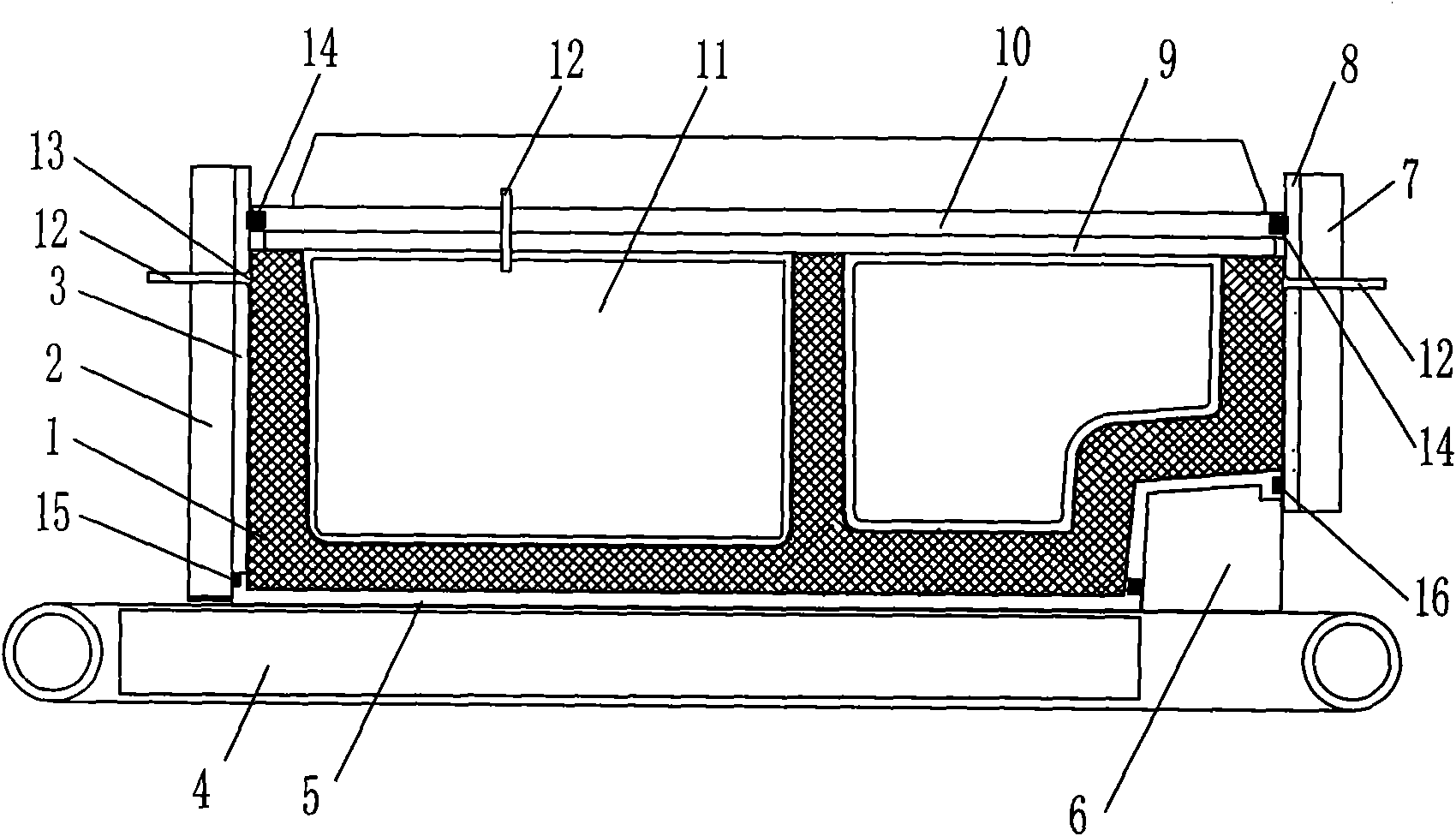

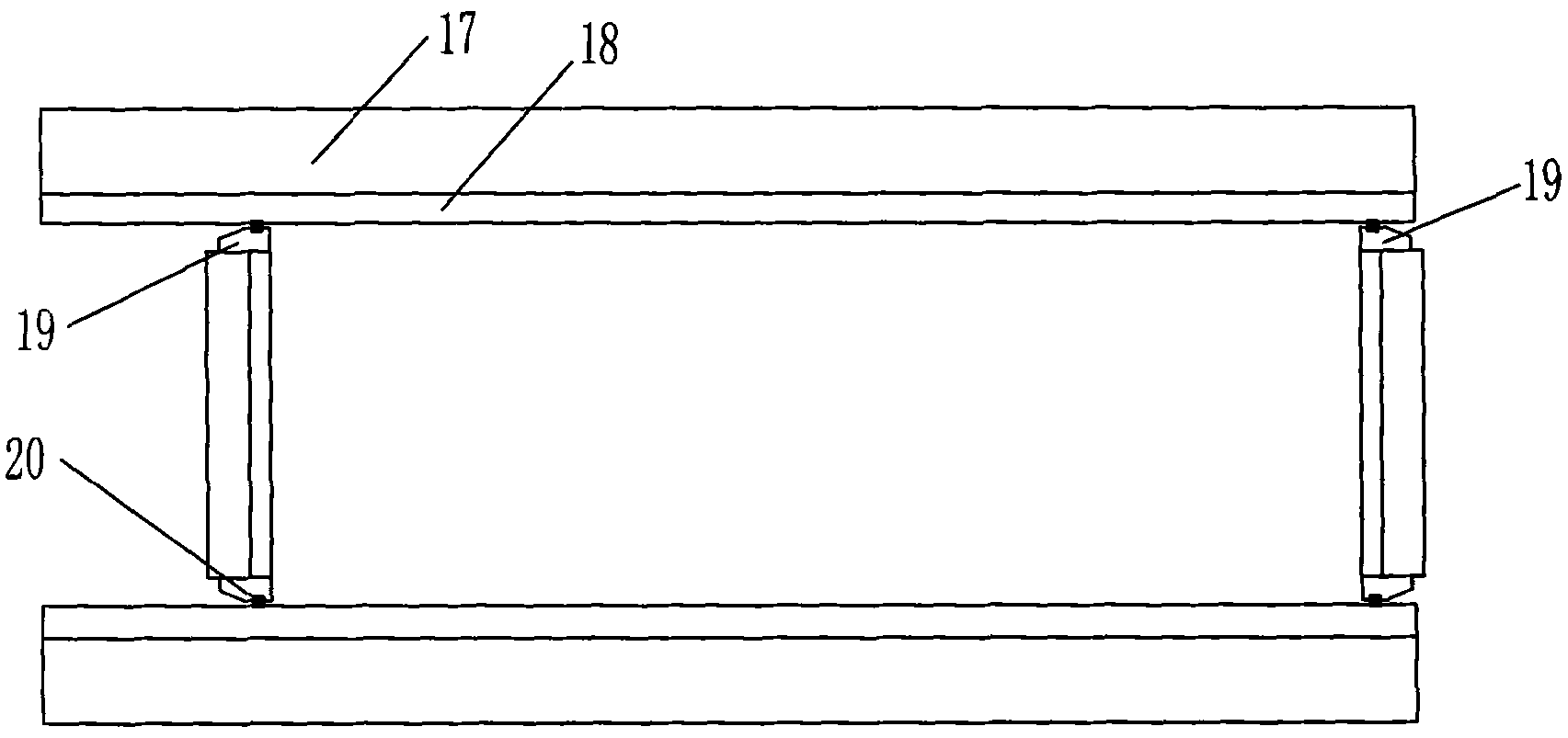

[0032] In concrete implementation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com