Peanut antihypertensive peptide and preparation method thereof

A blood pressure-lowering peptide and peanut technology, applied in the field of medicine, can solve the problems of insufficient utilization of peanut cake, backward deep processing technology, single product variety structure, etc., achieve strong ACE inhibitory activity, obvious blood pressure lowering effect, and no toxic side effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

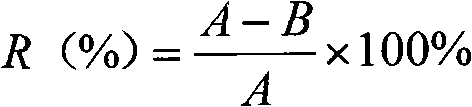

Method used

Image

Examples

Embodiment 1

[0033] The preparation method is carried out as follows:

[0034] a. Raw material pretreatment: use cold-pressed peanut cake as raw material, pulverize to 80 mesh, then add water to dissolve according to cold-pressed peanut cake powder: water = 1:10 weight parts, then adjust pH=8 with 3mol / L NaOH, at 80 Extract at ℃ for 1 hour, centrifuge with a centrifuge at 3500r / min for 10min, take the supernatant, and then add 3mol / L citric acid to the supernatant to control the pH of the supernatant to 5. After the acid precipitation is completed, use Centrifuge at 3000r / min for 30min to collect the precipitate;

[0035] b. Enzyme treatment: take the precipitate in step a and dissolve it in water, then add alkaline protease according to the ratio of alkaline protease: precipitate aqueous solution = 1: 8 parts by weight, and enzymolyze it for 60 minutes at 47.6 ° C and pH = 7.93. The dosage of protease is 75U / g protein to obtain enzymatic hydrolyzate;

[0036] c. Enzyme inactivation: Use...

Embodiment 2

[0040] The preparation method is carried out as follows:

[0041] a. Raw material pretreatment: use cold-pressed peanut cake as raw material, pulverize to 100 mesh, then add water to dissolve according to cold-pressed peanut cake powder: water = 1:8 weight parts, then adjust pH=9 with 3mol / L NaOH, at 30 Extract at ℃ for 5 hours, centrifuge with a centrifuge at 3000r / min for 30min, take the supernatant, and then add 3mol / L citric acid to the supernatant to control the pH of the supernatant to 4. After the acid precipitation is completed, use Centrifuge at 3500r / min for 10min to collect the precipitate;

[0042] b. Enzyme treatment: take the precipitate in step a and dissolve it with water, then add alkaline protease according to the ratio of alkaline protease:precipitate aqueous solution=1:10 parts by weight, and enzymolyze it at 44.9°C and pH=8.15 for 30min, then alkaline The dosage of protease is 150U / g protein to obtain enzymatic hydrolyzate;

[0043]c. Enzyme inactivation...

Embodiment 3

[0047] The preparation method is carried out as follows:

[0048] a. Raw material pretreatment: use cold-pressed peanut cake as raw material, pulverize to 90 mesh, then add water to dissolve according to cold-pressed peanut cake powder: water = 1:9 weight parts, then adjust pH=8.5 with 3mol / L NaOH, at 50 Extract at ℃ for 3 hours, centrifuge with a centrifuge at 3300r / min for 20min, take the supernatant, and then add 3mol / L citric acid to the supernatant to control the pH of the supernatant to 4.5. After the acid precipitation is completed, use Centrifuge at 3300r / min for 20min to collect the precipitate:

[0049] b. Enzyme treatment: take the precipitate in step a and dissolve it in water, then add alkaline protease according to the ratio of alkaline protease: precipitate aqueous solution = 1:9 parts by weight, and enzymolyze it for 45 minutes at 46.1°C and pH=8.05, and then alkaline The dosage of protease is 110U / g protein, and the enzymolysis solution is obtained;

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com