Spray drying tower for preparing powder

A spray drying tower and tower body technology, which is applied in the direction of drying solid materials, drying gas arrangement, drying, etc., can solve the problems of high damage rate, large product deformation, and reduced pressing efficiency, so as to improve pressing forming efficiency and reduce The effect of planing and grinding and reducing the shrinkage of firing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

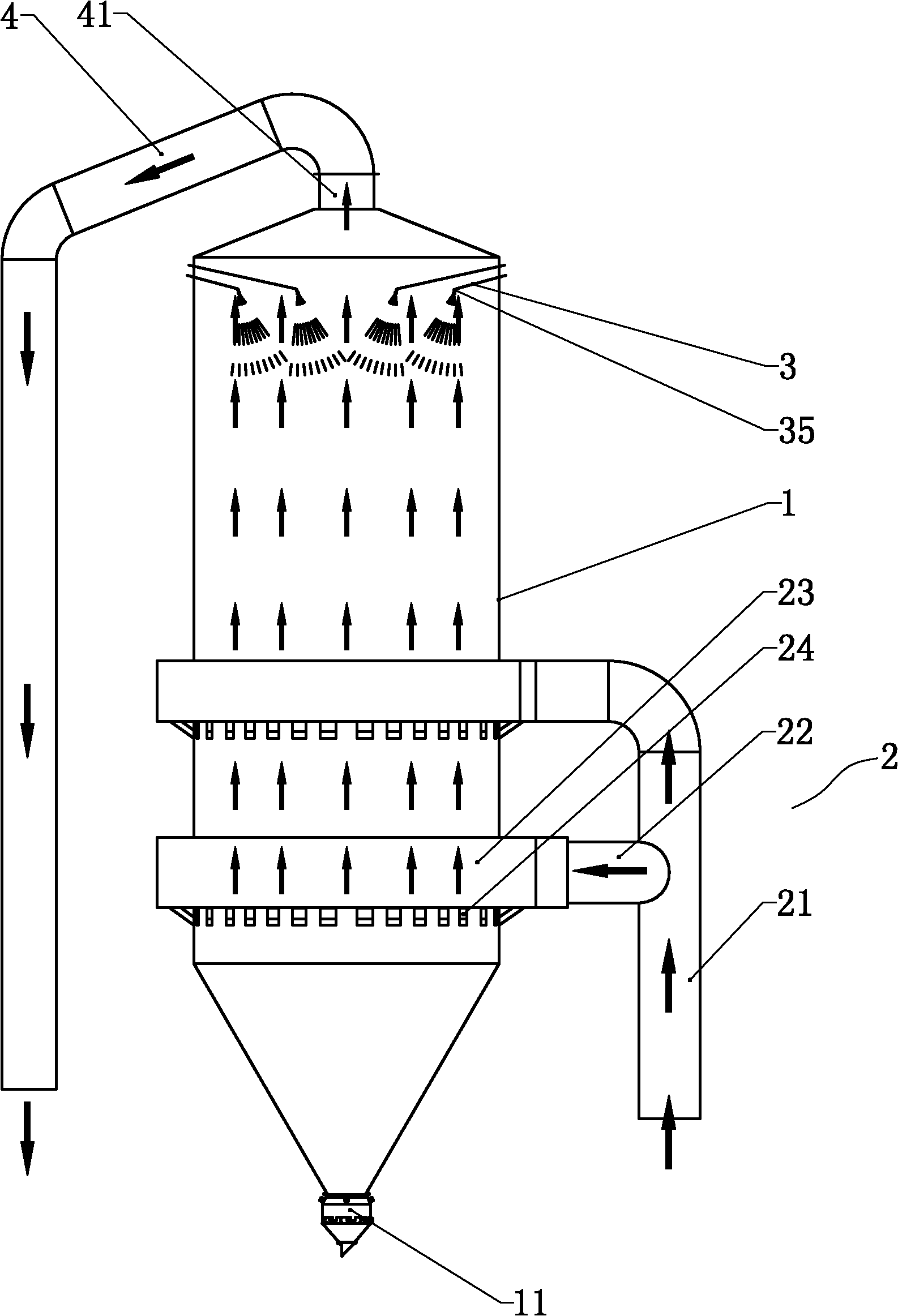

[0039] Such as figure 1 As shown, the spray drying tower for ceramic powder making according to the present invention includes a tower body 1, the bottom of the tower body 1 is provided with a powder outlet 11, and the top of the tower body is provided with an air outlet connected to the exhaust device 4 41. The tower body 1 is also provided with a hot air supply device 2 and a slurry supply atomization device 3 .

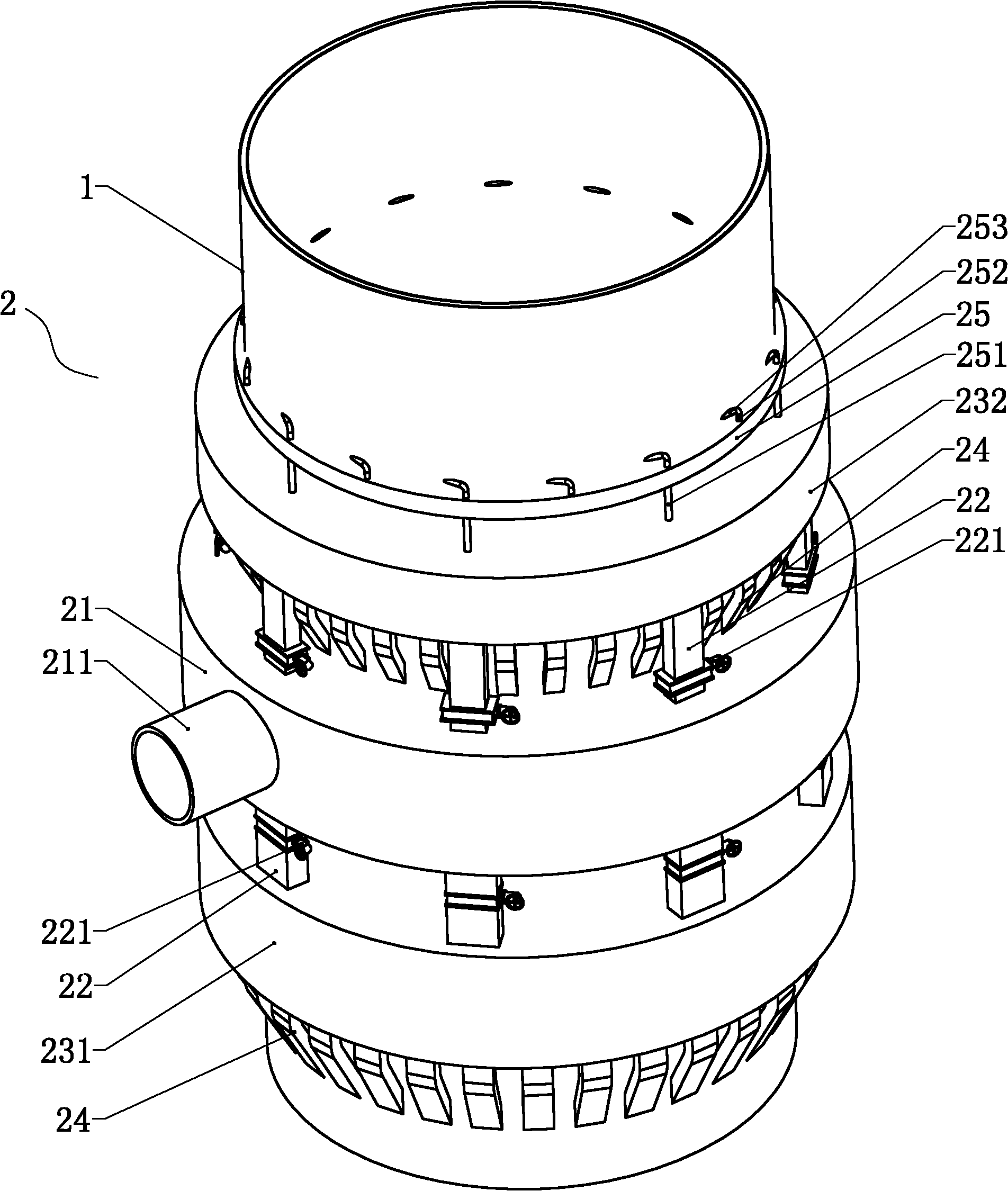

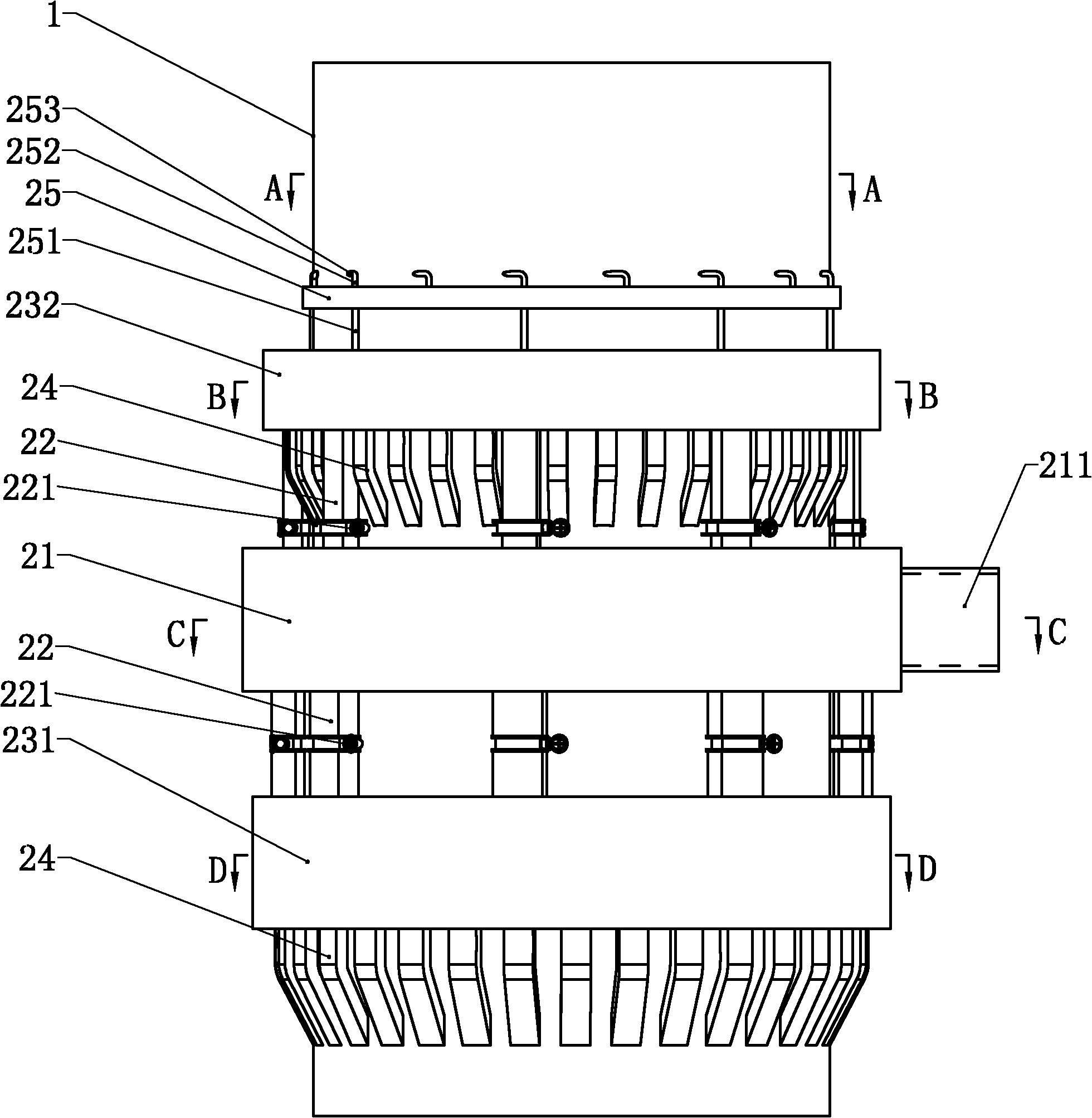

[0040] The hot air supply device 2 includes a balanced air pipe 21 and two hot air pipes 23. The balanced air pipe 21 is connected to the hot air source through a pipeline, and the two hot air pipes 23 are respectively arranged around the outer wall of the tower body 1 on the peripheral wall of the tower body. The middle part and the lower part, and communicate with the balance air pipe 21 through a regulating pipe 22 respectively. Corresponding to each hot-blast pipe 23 is provided with some hot-blast sub-pipes 24, one end of each hot-blast sub-pipe 24 communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com