Mixed concentric single and two-layer winding for servo permanent magnet synchronous motor

A technology of concentric winding and permanent magnet synchronization, which is applied to the shape/style/structure of synchronous machine parts and winding conductors, and can solve problems such as small torque, large torque ripple, and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

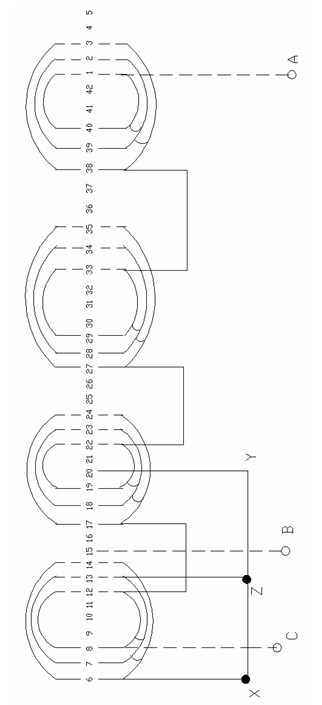

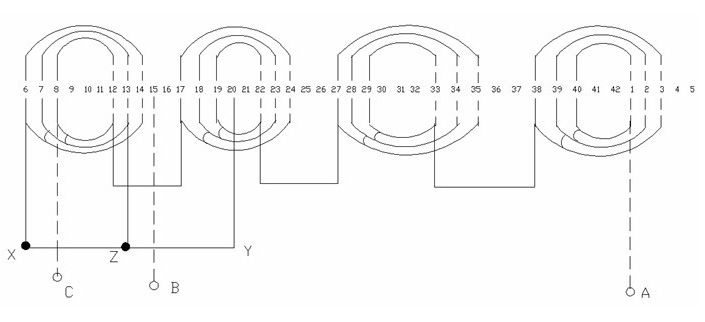

[0008] Such as figure 1 As shown, the number of stator slots of the motor is 42, the number of poles is 8 poles, the three-phase mixed concentric single-layer and double-layer windings of the 3-phase motor, and the stator winding of the motor is composed of two kinds of concentric windings. Phase A is composed of AX windings, and there are 2 concentric windings mixed. The first concentric winding is composed of 3 concentric coils, and the pitch is 8, 6, 4 from large circle to small circle; the number of turns of each coil, From the large circle to the small circle is 1, 3, 2; the second concentric type also consists of 3 concentric coils, and its pitch is 7, 5, 3 from the large circle to the small circle; the number of turns of each coil varies from large to small Circle to small circle is 2, 4, 2;

[0009] The first type of concentric winding and the second type of concentric winding are mixed to form a connection. Each phase winding is composed of 2 series in series, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com