Press roller device for vacuum rotary drum filter

A pressure roller device and filter technology, applied in the direction of filtration separation, moving filter element filter, separation method, etc., can solve the problems of shortening the service life of the pressure roller, reducing the working efficiency of the pressure roller, and poor corrosion resistance of the pressure roller body , to achieve strong corrosion resistance and wear resistance, reduce operation and maintenance costs, and smooth roll body rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings.

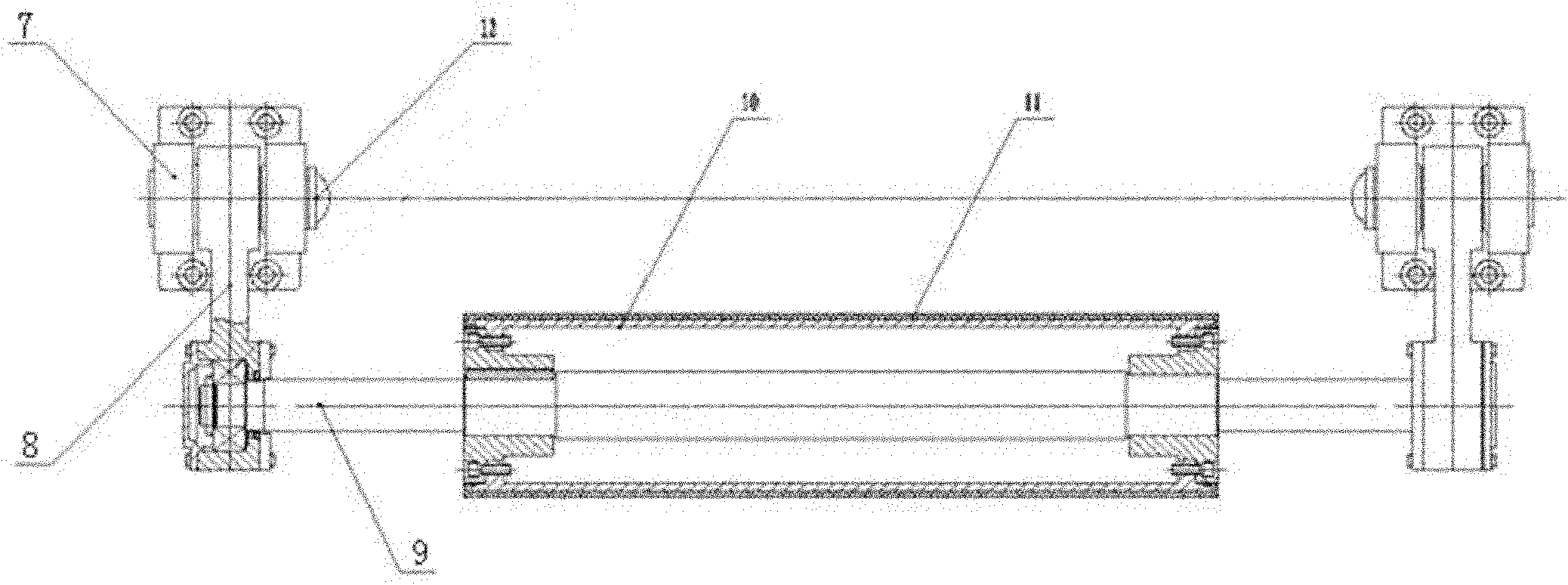

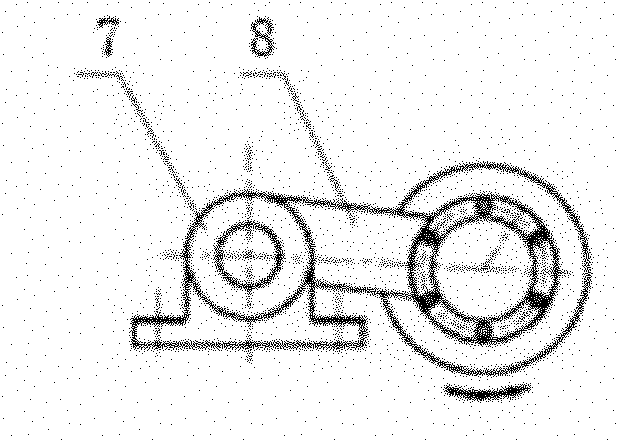

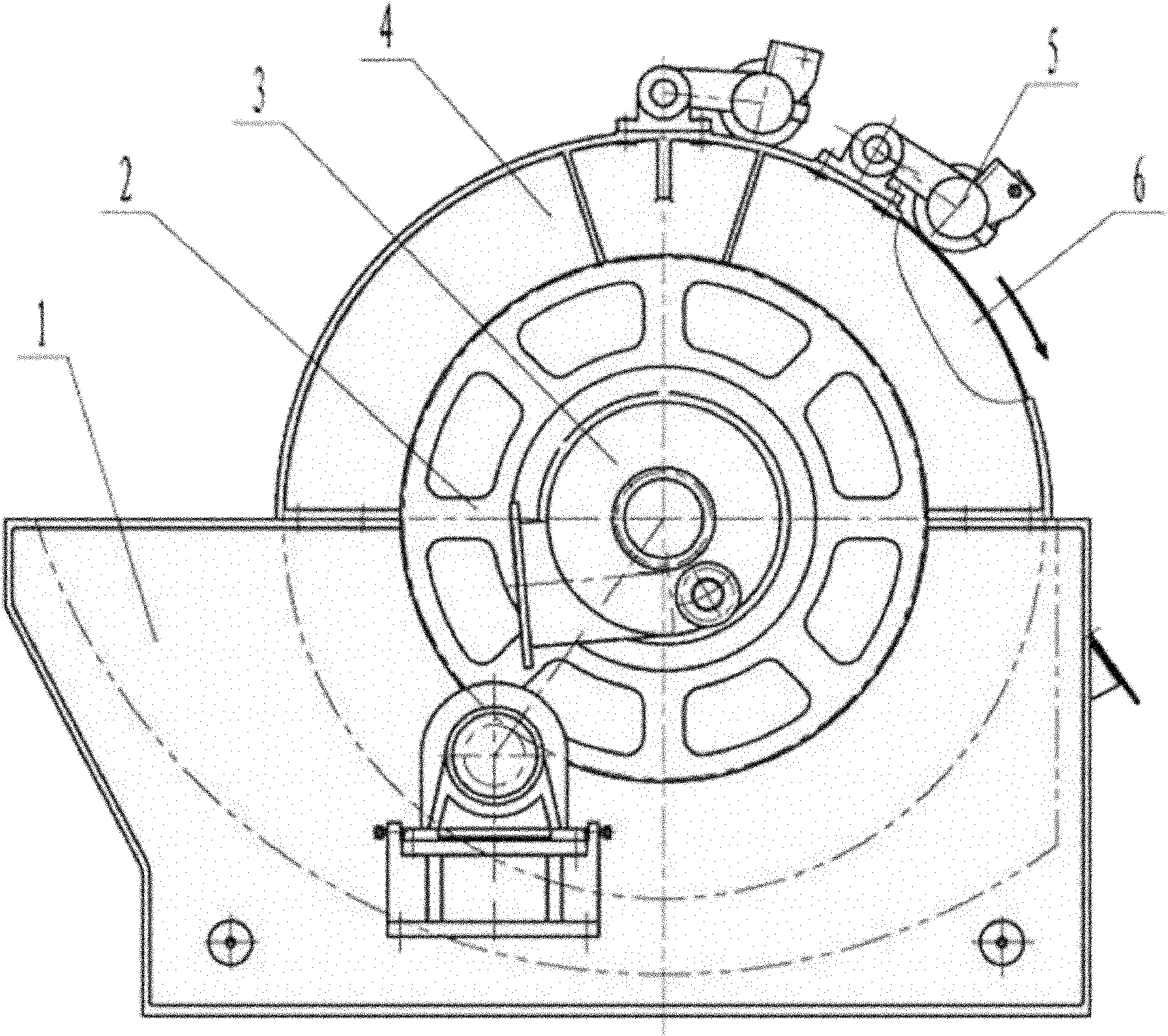

[0016] Such as figure 1 , figure 2 and image 3 As shown, the drum 6 is supported on the frame 4 by the journals at its two ends, and is immersed in the slurry tank 1 with a certain liquid level. The driving device 2 drives the drum 6 to rotate, and the distribution head 3 communicating with the drum 6 Connect the vacuum system, the drum 6 absorbs the filter slurry in the filter slurry tank 1, and forms a filter cake layer with a certain thickness on the outer peripheral surface of the drum 6 . The pressure roller device 5 is installed above the drum 6, and its centerline is parallel to the centerline of the drum 6; the two ends of the pressure roller body 10 in the pressure roller device 5 are connected with a pressure roller shaft 9, and the pressure roller shaft 9 is supported by a bearing 13 The two support arms 8 can rotate freely, the other end of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com