Method for preparing ultrapure copper ingot

A technology of ultra-pure copper and preparation process, which is applied in the field of preparation of ultra-pure copper ingots, which can solve problems such as the gap between density and theoretical density, difficulty in meeting special user requirements, and difficulty in avoiding pollution of melting crucibles, etc., to achieve diversification , improve product quality, optimize the effect of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Manually adjust the process parameters as follows for ultra-pure copper ingot casting:

[0023] Filament voltage

8V

20A

Auxiliary high voltage

1.0kV

bombardment current

1.3A

main high voltage

19kV

electron beam

2.2A

a focusing current

90mA

Two focusing currents

70mA

triple focus current

30mA

Accelerating pole current

54.2mA

A column of hole current

64mA

Two-lane hole current

63mA

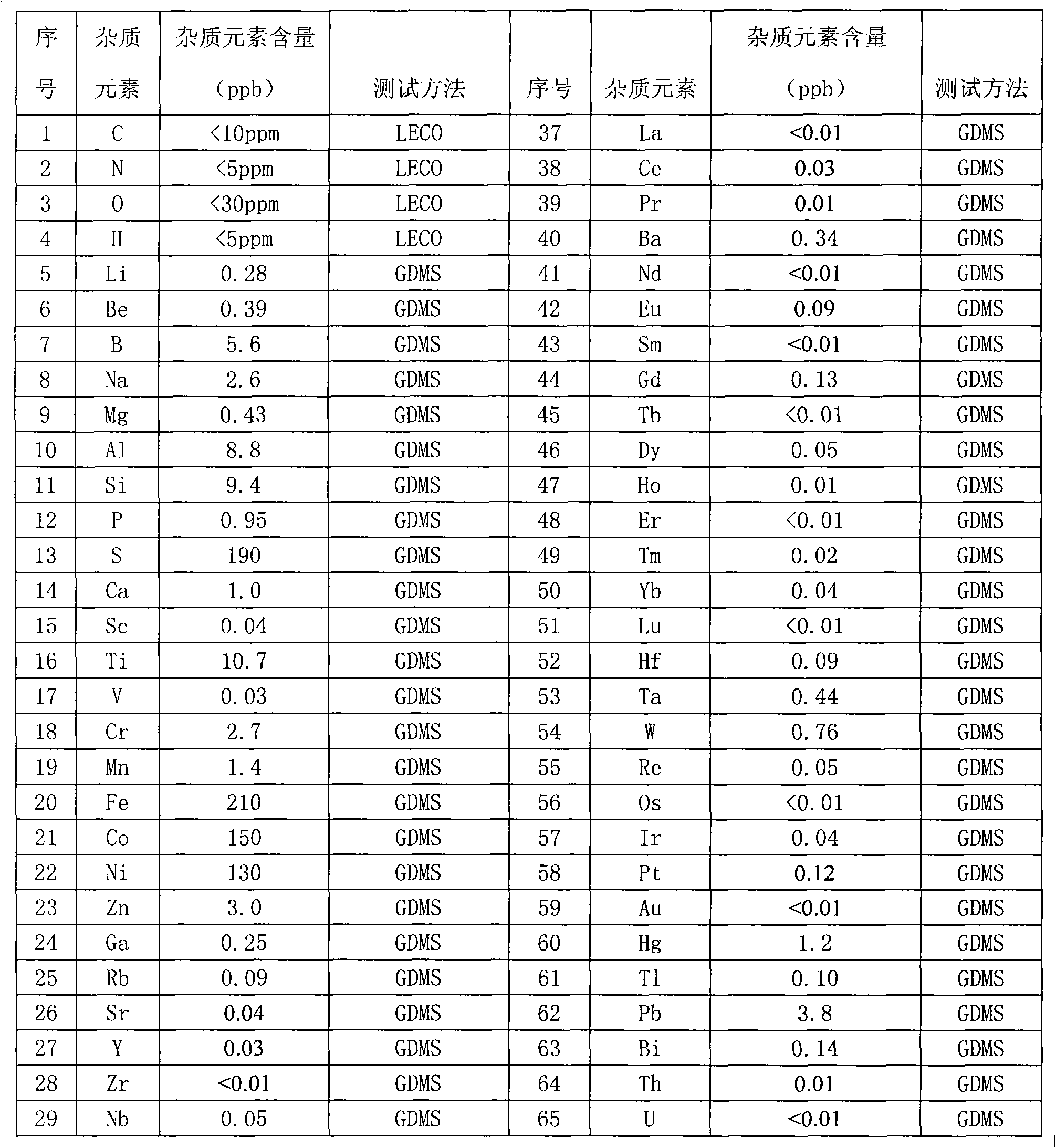

[0024] Test and analyze the samples of the ultrapure copper ingots prepared above. 68 non-gas elements were detected and analyzed by GDMS (glow discharge mass spectrometry), and 4 gas contents were detected and analyzed by LECO method. The results are shown in Table 1. The total non-gas impurity content is about 1ppm, and the purity of ultrapure copper ingot reaches 99.9999 %.

[0025] Table 1 Purity analysis results of ultrapure copper ingots

[0026] ...

Embodiment 2

[0029] Manually adjust the process parameters as follows for ultra-pure copper ingot casting:

[0030] Filament voltage

8.6V

24A

Auxiliary high voltage

1.2kV

bombardment current

1.5A

main high voltage

21kV

electron beam

2.4A

a focusing current

100mA

Two focusing currents

74mA

triple focus current

46mA

Accelerating pole current

63.1mA

A column of hole current

72.5mA

Two-lane hole current

70.3mA

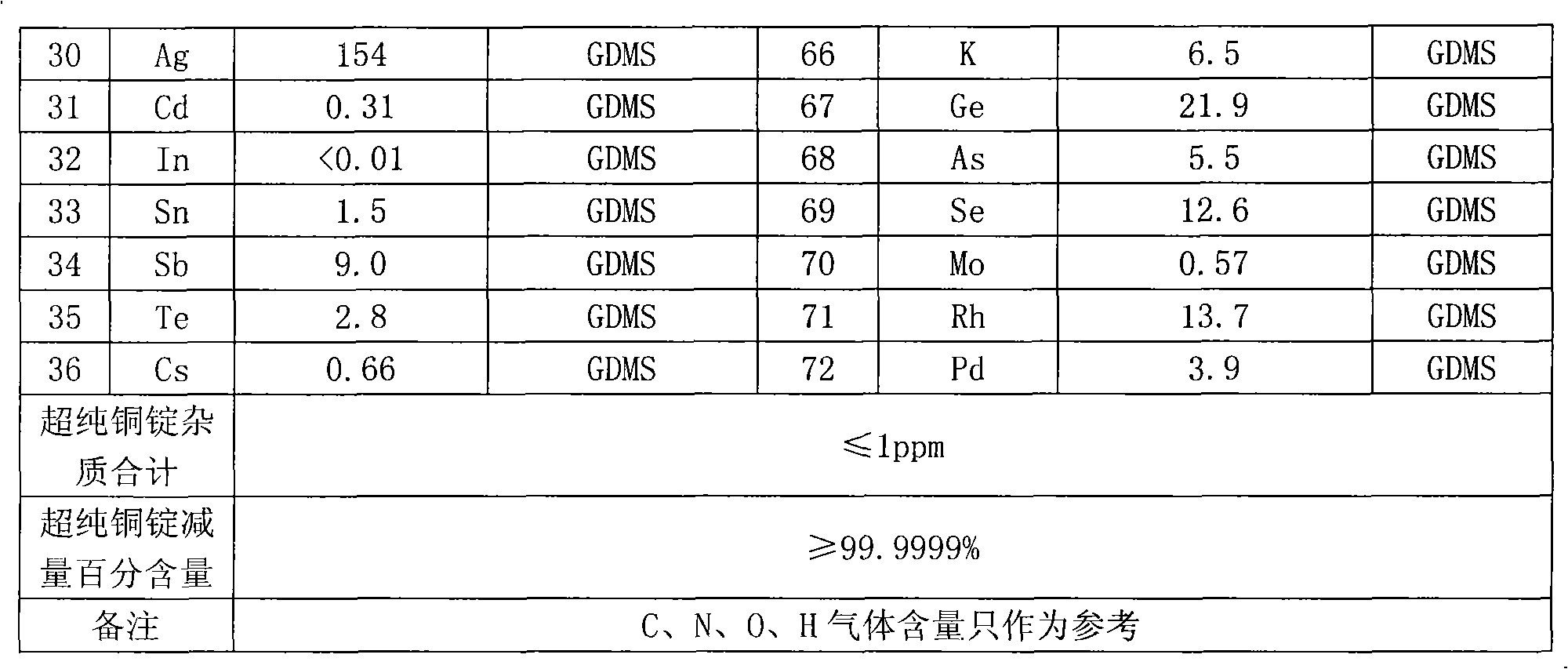

[0031] Test and analyze the samples of the ultrapure copper ingots prepared above. 68 non-gas elements were detected and analyzed by GDMS (glow discharge mass spectrometry), and 4 kinds of gas content were detected and analyzed by LECO method. The results are shown in Table 2. The total non-gas impurity content is about 0.8ppm, and the purity of ultra-pure copper ingot reaches 99.99992%.

[0032] Table 2 Purity analysis results of ultrapure copper i...

Embodiment 3

[0036] Manually adjust the process parameters as follows for ultra-pure copper ingot casting:

[0037] Filament voltage

9.3V

28A

Auxiliary high voltage

1.3kV

bombardment current

1.6A

main high voltage

23kV

electron beam

2.4A

a focusing current

110mA

Two focusing currents

77mA

triple focus current

50mA

Accelerating pole current

66.5mA

A column of hole current

83mA

Two-lane hole current

79.4mA

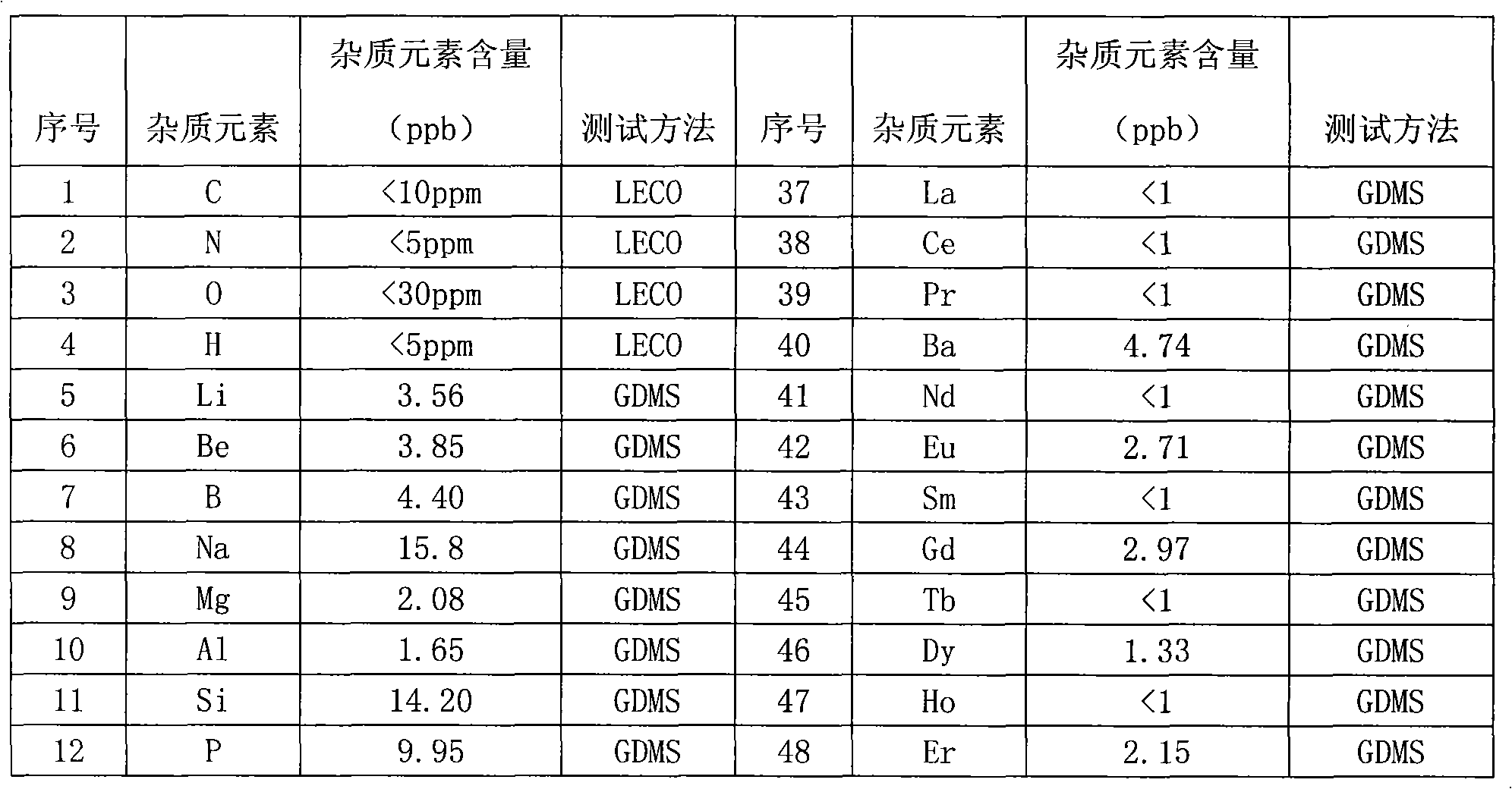

[0038] Test and analyze the samples of the ultrapure copper ingots prepared above. 68 non-gas elements were detected and analyzed by GDMS (glow discharge mass spectrometry), and 4 gas contents were detected and analyzed by LECO method. The results are shown in Table 3. The total non-gas impurity content is about 0.8ppm, and the purity of the ultra-pure copper ingot reaches 0.8 ppm. 99.99992%.

[0039] Table 3 Purity analysis results of ultra-pure copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com