Method for preparing low-caffeine high-tea polyphenol tea powder

A technology of low caffeine and tea polyphenols, applied in the field of bioengineering, can solve the problems of tea polyphenols toxic substances, complex process of tea polyphenols, harm to human health, etc., and achieve the effect of environmental friendliness, low cost and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

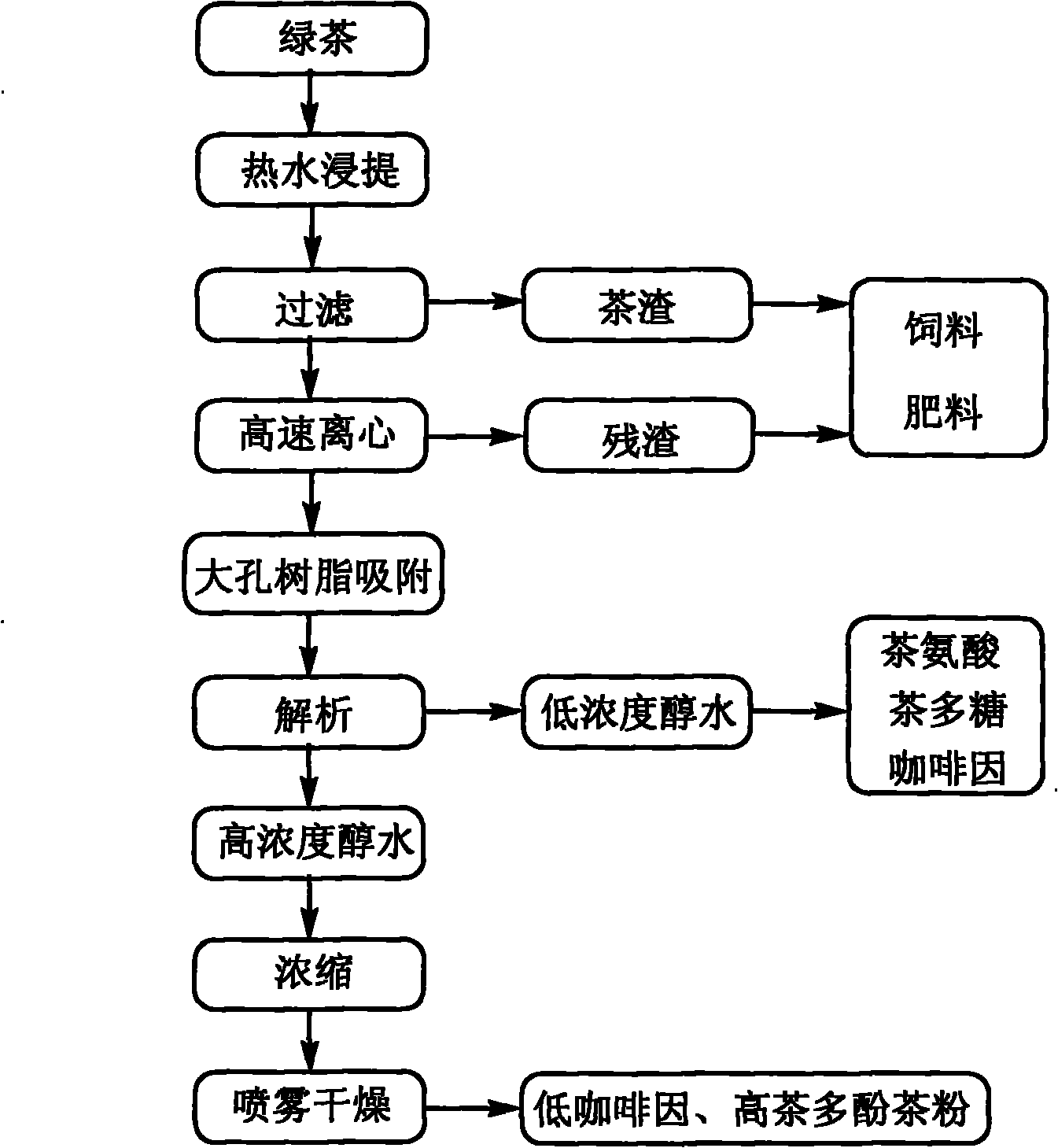

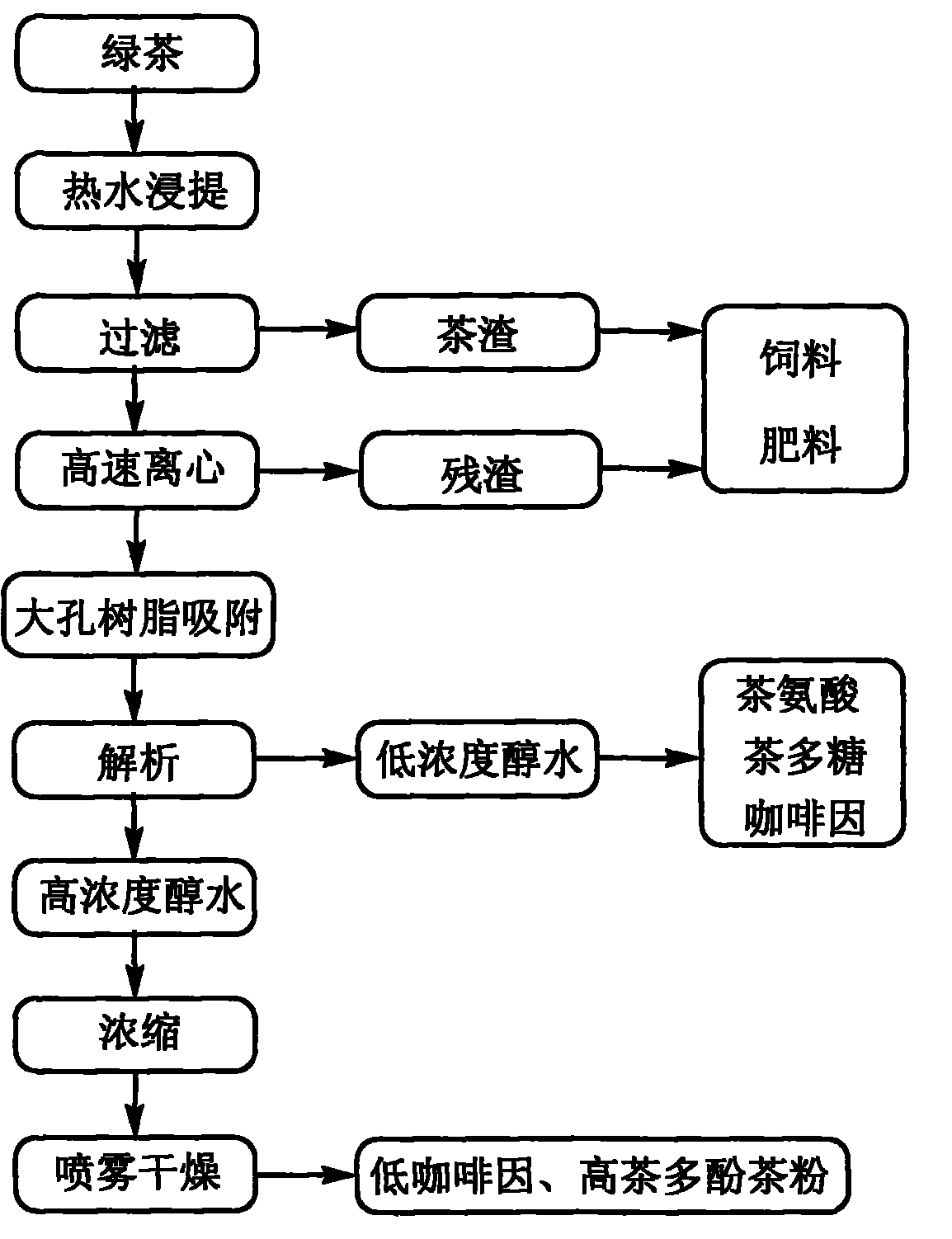

preparation example Construction

[0022] The invention provides a method for preparing tea powder with low caffeine and high tea polyphenols, which comprises a step of extracting tea leaves and rough filtering, a step of ultra-high-speed centrifugation of the filtrate after rough filtering, and a step of using the centrifuged liquid through large pores The steps of resin adsorption include a step of separating caffeine and tea polyphenols by graded eluting with ethanol aqueous solution, a step of concentrating the eluate of tea polyphenols, and a step of drying the concentrate.

[0023] Further, in the steps of tea extraction and coarse filtration, add water to the tea leaves, the weight of the water is 8-15 times the weight of the tea raw materials, heat to 50-90°C, stir and extract for 20-60min, filter .

[0024] Further, the steps of tea extraction and coarse filtration can be repeated more than once.

[0025] Further, in a step of separating caffeine and tea polyphenols by graded elution with aqueous etha...

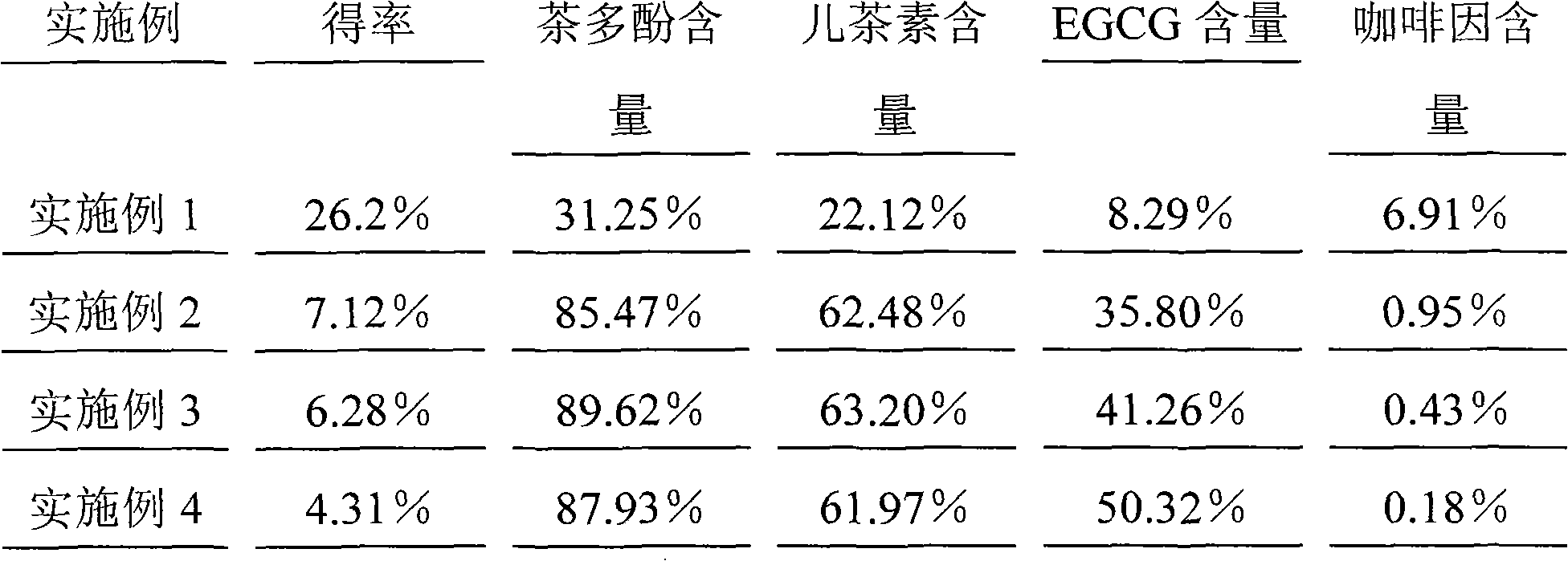

Embodiment 1

[0035] Embodiment 1 The preparation of green tea extract

[0036] Add 2000L pure water to 200kg green tea, heat to 80°C, stir (speed 20r / min) to extract for 35min, filter, the filtrate is cooled to 38°C by heat exchange, add 1000L pure water to the filter residue, stir and elute at room temperature for 30min, and combine the extracts; 10000r / min continuous centrifugation to obtain clarified green tea extract, which is put into the clarified liquid storage tank.

Embodiment 2

[0037] Embodiment 2 Preparation of low caffeine and high tea polyphenol tea powder of the present invention

[0038] The green tea extract in Example 1 was adsorbed by macroporous resin ADS-F8 (Tianjin Nankai Hecheng Technology Co., Ltd.); according to the amount of 1.5L resin (fully swollen in 35°C water) for 1kg of tea leaves, the sample was loaded for adsorption, and the After the sample is finished, after washing with water for 8CV (column bed volume), three column volumes are eluted with 100% ethanol, diluted with water, concentrated to no alcohol smell, and spray-dried to obtain low caffeine and high tea polyphenol tea powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com