A test method for impurities on the surface of polyester fibers after dyeing cheese

A polyester fiber and testing method technology, applied in fiber processing, ultrasonic/sonic fiber processing, textile material inspection, etc., can solve problems such as greater impact on product quality, pollution of looms and sewing machines, and inability to accurately grasp the quality of polyester fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

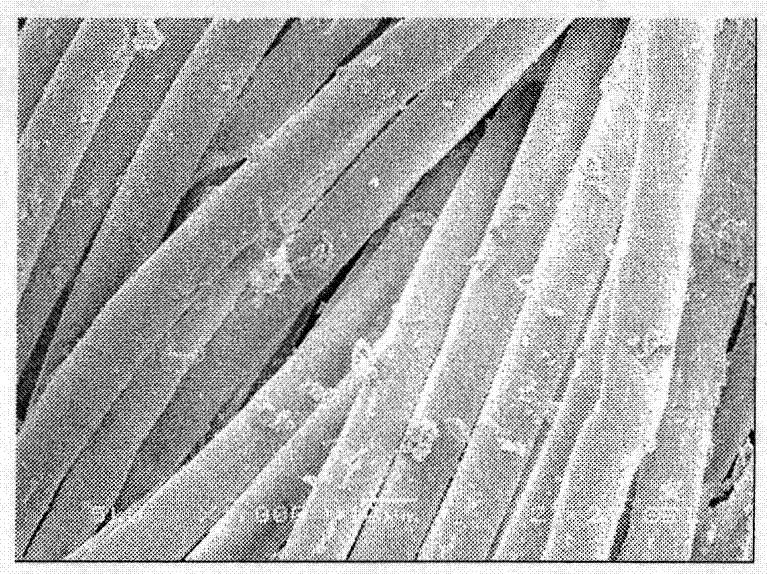

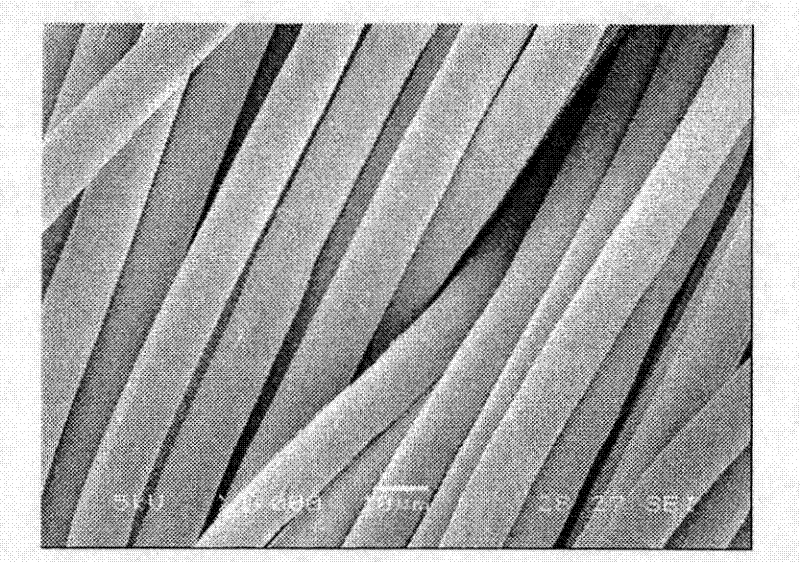

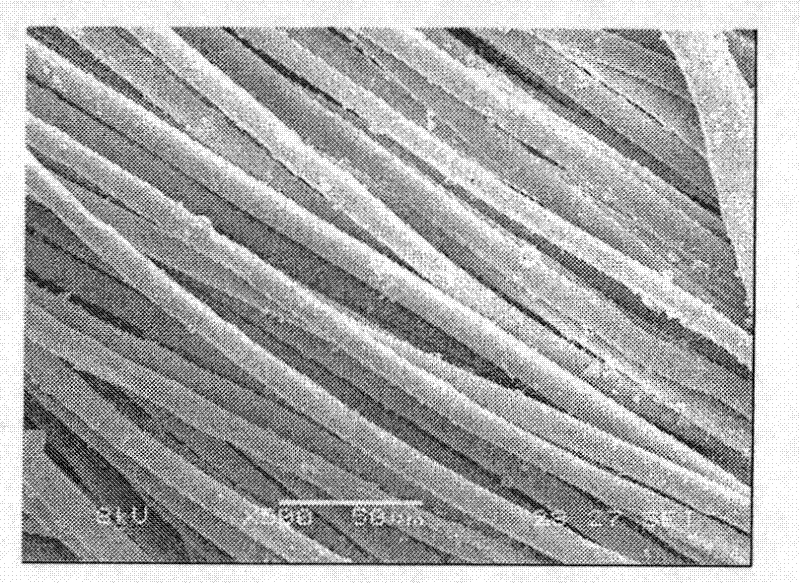

Image

Examples

Embodiment 1

[0073] For yarn dyed 20 S Test of foreign matter content on the surface of package dyed polyester yarn.

[0074] The measured 20 of this embodiment S Pure polyester yarn is polyester yarn produced by a small chemical fiber factory. The dyed color is navy blue. It is used for weaving yarn-dyed weaving. The color fastness to dry rubbing of the fiber is grade 4, and the strength loss before and after dyeing is less than 5%. test.

[0075] A method for testing polyester fiber surface impurities after cheese dyeing, said method comprising the steps of:

[0076] (1) Sampling

[0077] Remove 9g of yarn on the surface of the bobbin from the polyester fiber bobbin dyed by cheese, and then take 3 samples continuously from the outer layer as outer layer samples. When the weight is 50g, take 3 samples continuously as inner layer samples;

[0078] (2) Sample weighing

[0079] Each sample obtained in step (1) is dried, and the drying is carried out in an oven. When the temperature is ...

Embodiment 2

[0094] 42 S / 2 Measurement of foreign matter content on the surface of cheese dyed polyester sewing thread.

[0095] 42 measured in this embodiment S / 2 The raw material of polyester sewing thread is staple fiber for polyester sewing thread produced by a large chemical fiber factory. The dyed color is dark black, and the color fastness to dry rubbing is grade 4. The content of impurities on the surface is tested.

[0096] A method for testing polyester fiber surface impurities after cheese dyeing, said method comprising the steps of:

[0097] (1) Sampling

[0098] Remove 10g of yarn on the surface of the bobbin from the dyed polyester fiber bobbin of the bobbin, and then take 3 samples continuously from the outer layer as the outer layer sample. When it is 90g, take 5 samples continuously as inner layer samples;

[0099] (2) Sample weighing

[0100] Each sample obtained in step (1) was dried, and the drying was carried out in an oven for 2 hours at a temperature of 90° C....

Embodiment 3

[0115] For yarn dyed 20 S Test of foreign matter content on the surface of package dyed polyester yarn.

[0116] The measured 20 of this embodiment S Pure polyester yarn is polyester yarn produced by a small chemical fiber factory. The dyed color is navy blue. It is used for weaving yarn-dyed weaving. The color fastness to dry rubbing of the fiber is grade 4, and the strength loss before and after dyeing is less than 5%. test.

[0117] A method for testing polyester fiber surface impurities after cheese dyeing, said method comprising the steps of:

[0118] (1) Sampling

[0119] Remove 8g of yarn on the surface of the bobbin from the dyed polyester fiber bobbin of the bobbin, and then take 5 samples continuously from the outer layer as the outer layer sample. When it is 100g, take 3 samples continuously as inner layer samples;

[0120] (2) Sample weighing

[0121] Each sample obtained in step (1) is dried, and the drying is carried out in an oven. When the temperature is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com