A new type of three-dimensional sandwich flame retardant composite insulation board

A flame retardant composite and thermal insulation board technology, applied in thermal insulation, building components and other directions, can solve the problems of poor thermal insulation performance, easy to produce cracks, poor effect, etc., to achieve excellent fire prevention, reduce shrinkage, and improve the overall performance of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

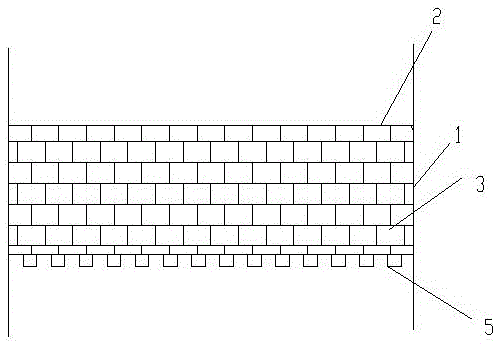

[0018] Such as figure 1 As shown, a new three-dimensional sandwich flame-retardant composite insulation board 1 includes an upper fabric surface 2, an intermediate core structure 3 and a lower fabric surface 5, and the intermediate core structure 3 is supported by a three-dimensional sandwich fabric material, which is lightweight The aggregate is the filling matrix, the particle size of the lightweight aggregate is 0-10mm, the middle core material structure 3 connects the upper fabric surface 2 and the lower fabric surface 5, the upper fabric surface 2 is a plane structure, and the thickness of the three-dimensional sandwich layer is 2 -100mm, the lower fabric surface 5 is a concave-convex structure, the height of the convex surface is 0.5-20mm, and the width of the concave surface is 10-600mm.

[0019] In this embodiment, the three-dimensional sandwich fabric material is a glass fiber three-dimensional sandwich fabric, a carbon fiber three-dimensional sandwich fabric, an aram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com