TFT array structure and manufacturing method thereof

An array structure and common electrode technology, applied in semiconductor/solid-state device manufacturing, instrumentation, optics, etc., can solve the problem of increasing the overlapping area of gate electrode scanning lines and data lines and storage capacitors, and improving storage capacitors that cannot take into account the aperture ratio Optimize and increase the parasitic capacitance of the signal line to achieve the effect of increasing the storage capacitance, optimizing the design, and reducing the lead resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

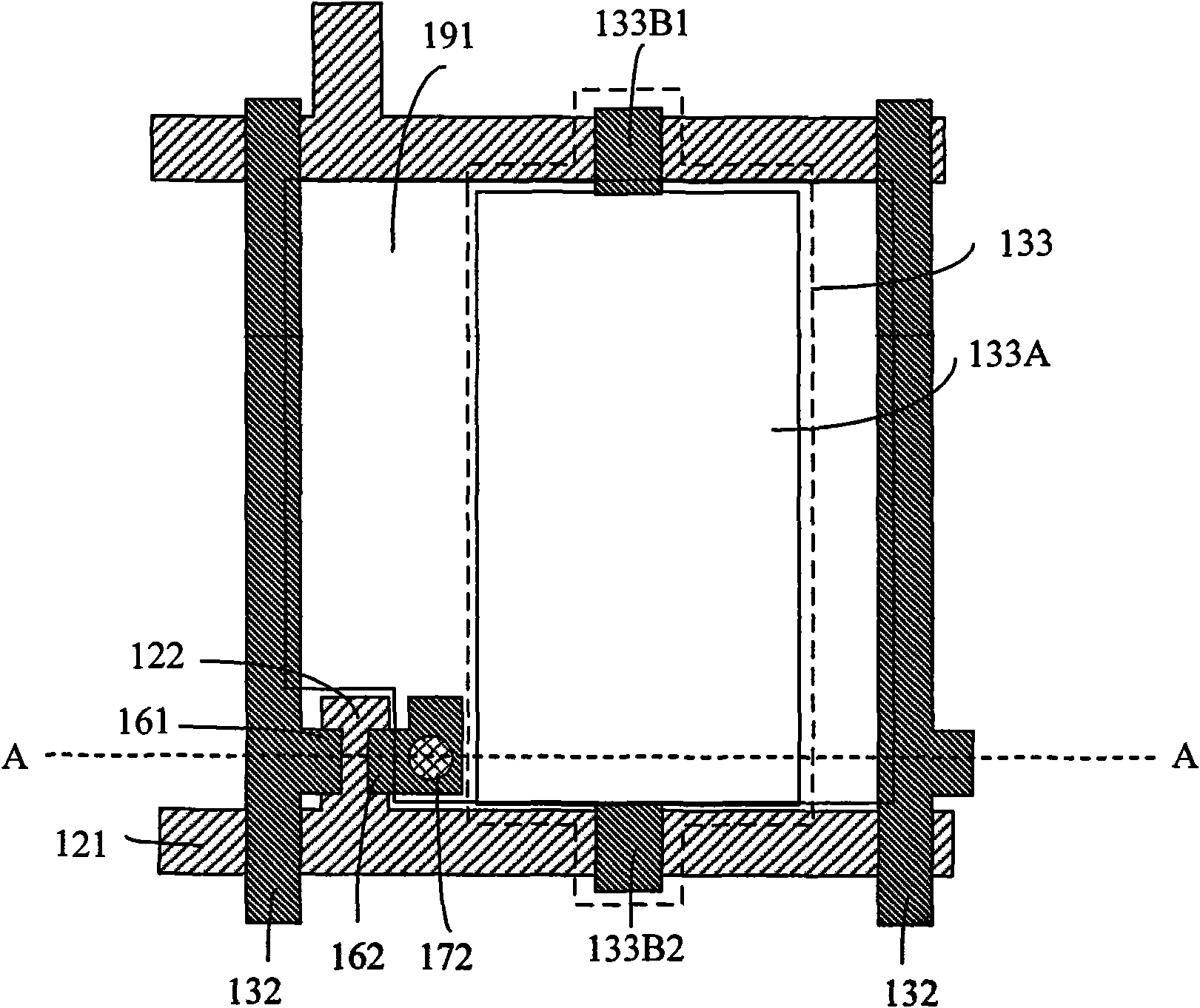

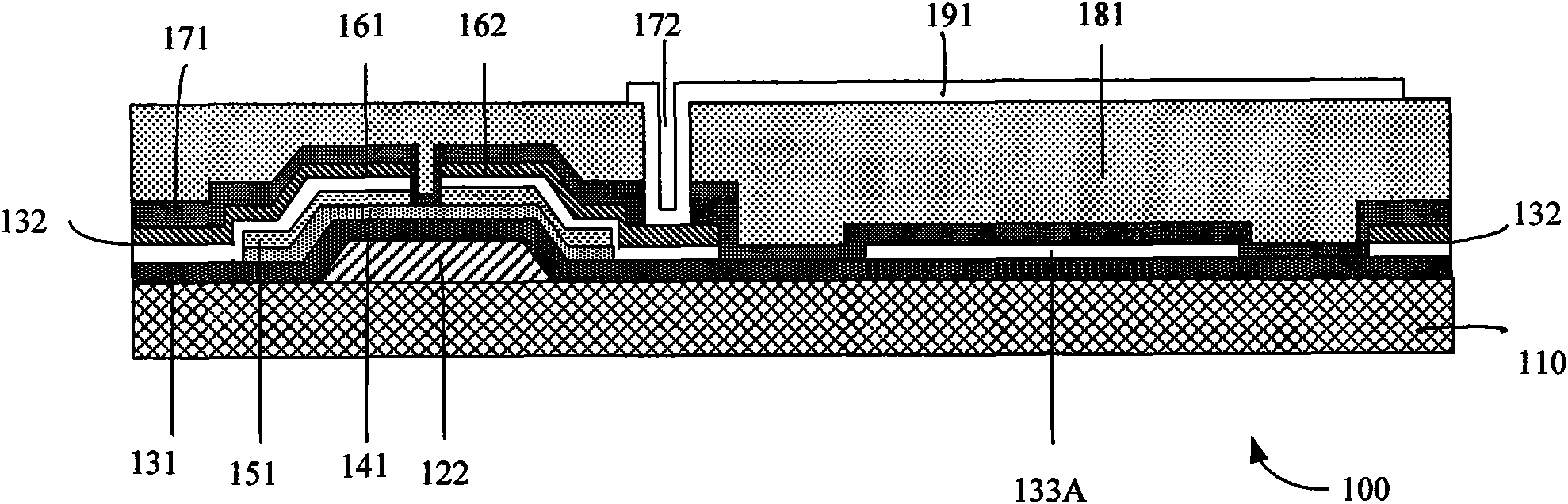

[0054]In order to make the purpose and features of the present invention more comprehensible, the specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

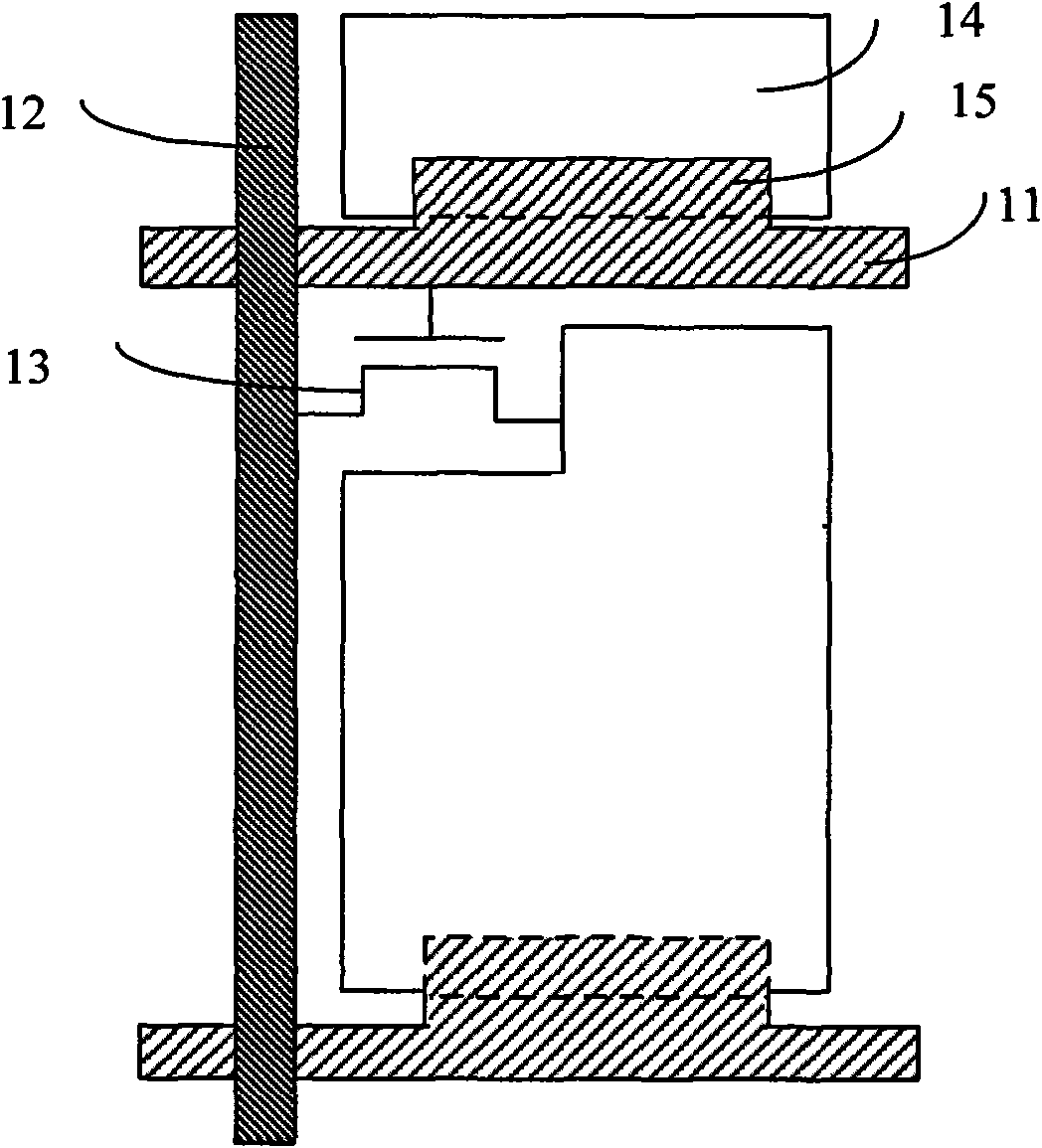

[0055] As mentioned in the background art, the lower electrode (ie, the common electrode) of the storage capacitor in the existing TFT array structure is made of a light-shielding material, so the two aspects of increasing the aperture ratio and optimizing the storage capacitor cannot be considered.

[0056] The core idea of the present invention is to use a half-tone mask to form an at least partially transparent common electrode under the pixel electrode, thereby replacing the opaque common electrode and the pixel electrode with a transparent common electrode to form a storage capacitor structure, which can greatly improve the opening. At the same time, by increasing the width of the transparent common electrode, the storage capacitance can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com