Self-circulation fuel cell control system and method thereof

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell grouping, fuel cell additives, etc., can solve problems such as difficult continuous work, difficult control, high working pressure of fuel cells, etc., to achieve high oxidant concentration, high operating The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

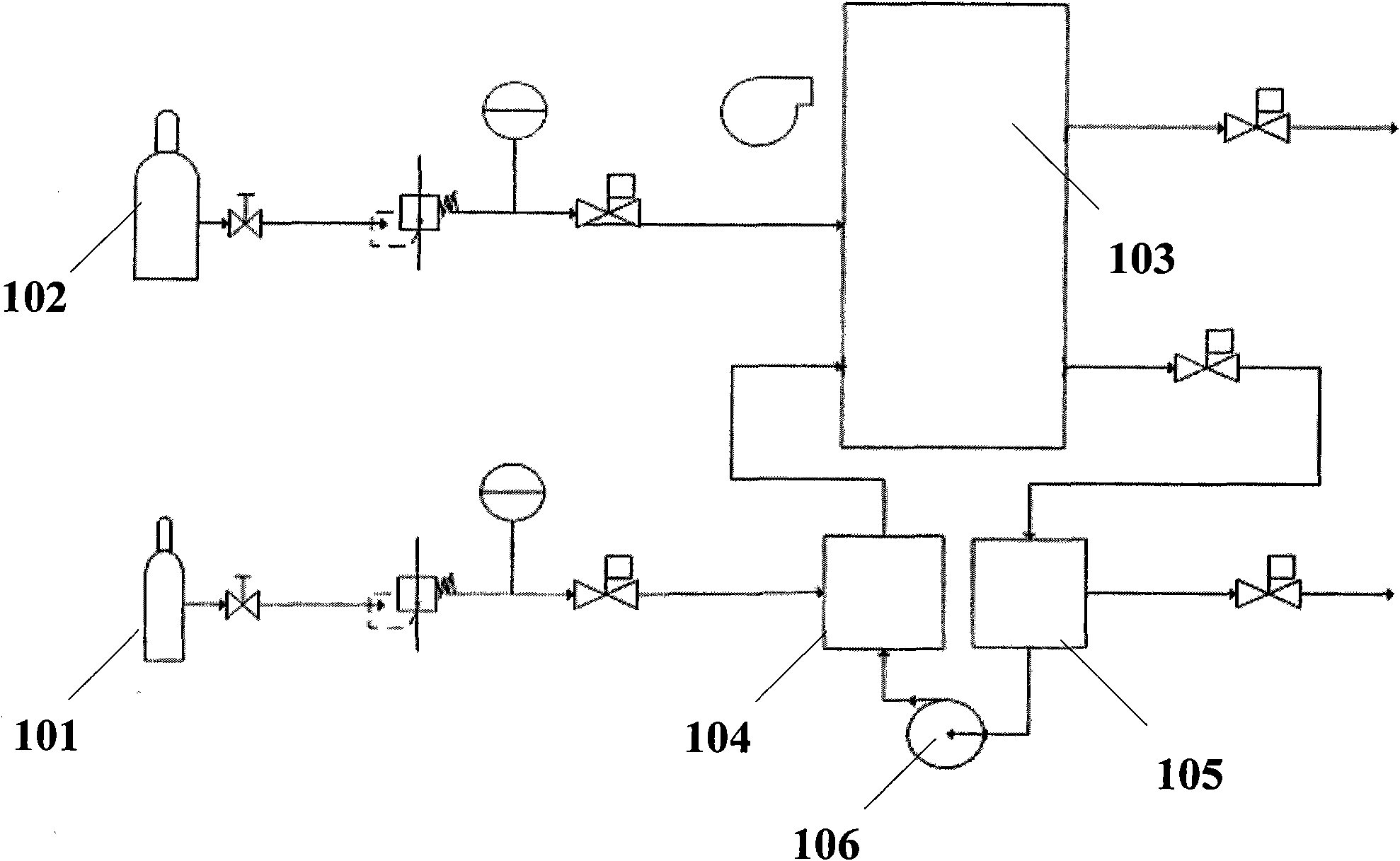

[0067] Such as figure 1 As shown, a ring fuel cell system includes a fuel cell stack 103 with a fuel channel and an oxidant channel, the fuel channel is provided with an oxidant container 101 for containing oxidant, and the oxidant container 101 is connected to the inlet of the fuel cell stack 103 A first mixer 104 is connected to the oxidant passage at the outlet end of the fuel cell stack 103, and a gas-water separator 105 and a first booster circulation pump 106 are arranged in sequence on the outlet end of the fuel cell stack 103, and the first booster circulation pump 106 The output end of is connected with the first mixer 104 pipeline. The outlet end of the fuel cell stack 103 drains intermittently to the gas-water separator 105 , the water is removed, and the gas is sucked into the first mixer 104 through the first pressurized circulating pump 106 , mixed with the oxidant, and then enters the fuel cell stack 103 . This solution is relatively reliable, but still require...

Embodiment 2

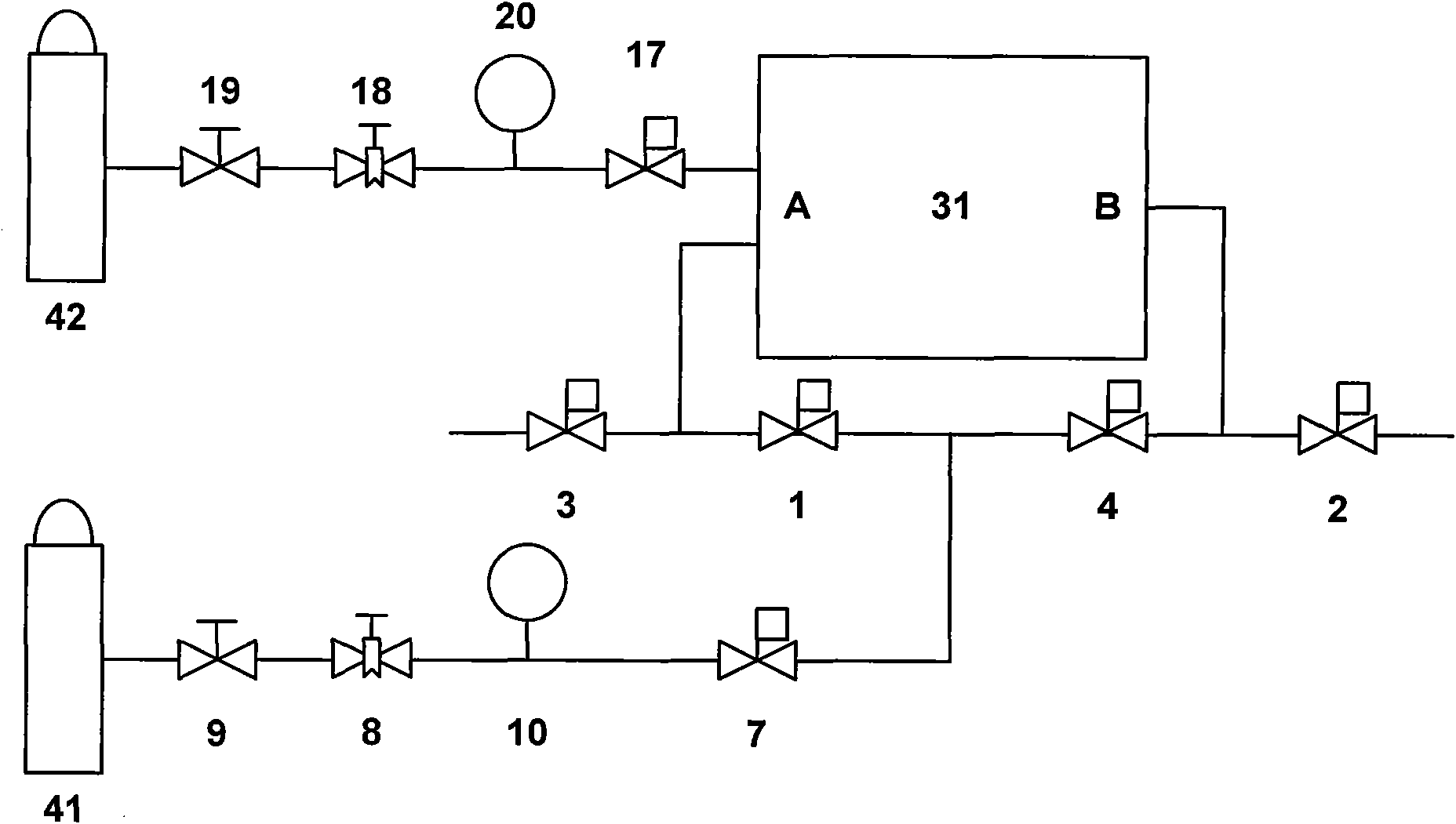

[0078] Such as image 3 As shown, a self-circulating fuel cell system of the present invention includes a fuel cell stack 31 provided with fuel channels and oxidant channels. The fuel cell stack 31 enters and exhausts bidirectionally. One end of the oxidant channel is provided with an oxidant container 41 for containing oxidant. Both ends of the fuel cell stack 31, a bypass pipe with a third solenoid valve 3 is connected between the first solenoid valve 1 and the fuel cell stack 31, and the fourth solenoid valve 4 is connected to the fuel cell stack 31. A bypass pipe with a second solenoid valve 2 is connected between the battery stacks 31 . The oxidant channel is sequentially connected with a stop valve 9 , a pressure regulating valve 8 , a pressure sensor 10 , and an inlet solenoid valve 7 . One end of the fuel channel is provided with a hydrogen container 42 for holding hydrogen, and the other end is divided into two paths, which are respectively connected to the two ends...

Embodiment 3

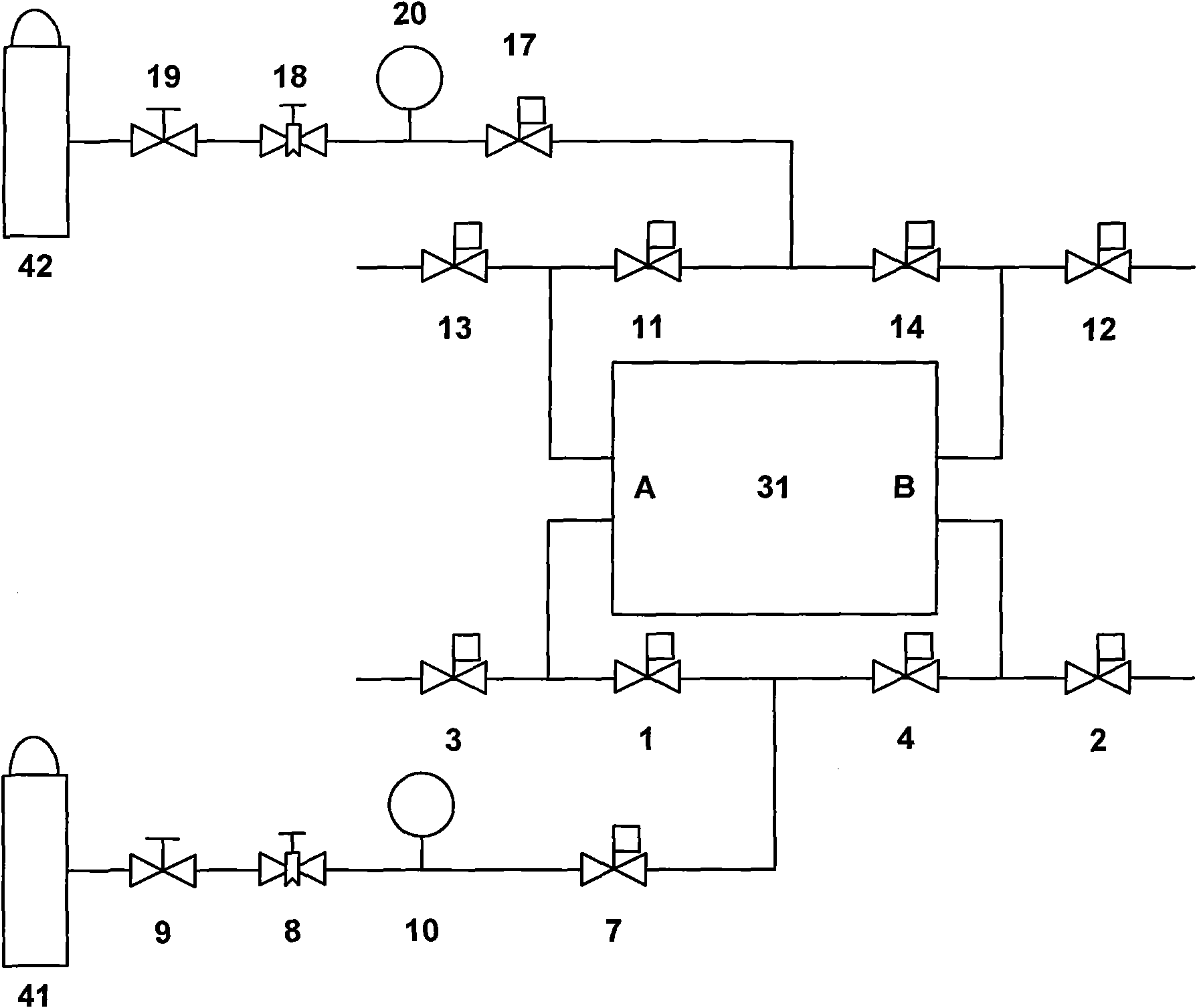

[0081] Such as Figure 4 As shown, a self-circulating fuel cell system of the present invention includes a fuel cell stack 31 provided with a fuel channel and an oxidant channel. The other end of the oxidant container 41 containing the oxidant is divided into two circuits, which are respectively connected to the two ends of the fuel cell stack 31 through the first electromagnetic valve 1 and the fourth electromagnetic valve 4. The first electromagnetic valve 1 and the fuel cell A first gas-water separator 5 is arranged between the electric stacks 31, and a bypass pipe with a third solenoid valve 3 is connected to the first gas-water separator 5, and the fourth solenoid valve 4 is connected to the fuel cell electric A second gas-water separator 6 is provided between the stacks 31 , and a bypass pipe with a second solenoid valve 2 is connected to the second gas-water separator 6 . The oxidant channel is sequentially connected with a stop valve 9 , a pressure regulating valve 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com