Composite adsorbent and preparation method and application thereof

A composite adsorption and composite powder technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve problems that hinder the promotion and use of sepiolite, difficult recycling of wastewater treatment, and unfavorable industrialization. Achieve the effects of enriching surface properties, improving alternating performance, and improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

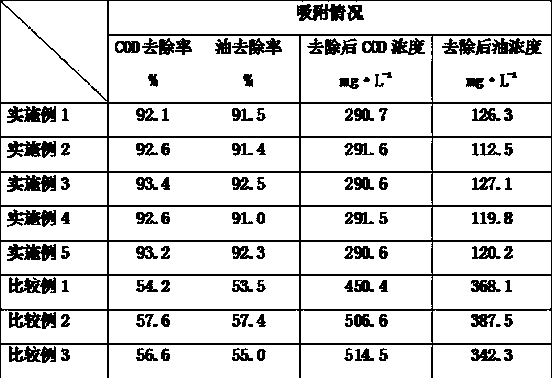

Examples

Embodiment 1

[0026] A preparation method of an adsorbent for petrochemical wastewater treatment, comprising the steps of:

[0027] (1) Preparation of composite powder gel: Take 15 parts of dedecyltrimethylphosphine bromide modified rectorite powder and 20 parts of tetraethylenepentamine modified sepiolite powder and disperse them in 100 parts of toluene and ultrasonically oscillate at room temperature for 1 hour, then warm up to 65°C, slowly add 20 parts of tetraethyl orthosilicate dropwise, and continue to stir until the solution becomes a solid phase; wash the solid phase with distilled water until the mass remains unchanged, Dry for 3 hours to obtain a composite powder gel;

[0028] (2) Preparation of modified composite adsorbent: Add the modified composite powder gel obtained in step (1) to 10 parts of quaternary ammonium salt tetramer surfactant, 6 parts of chitosan and 50 parts of toluene solvent Mix and stir evenly, then transfer the mixture to a polytetrafluoroethylene hydrotherma...

Embodiment 2

[0031] A preparation method of an adsorbent for petrochemical wastewater treatment, comprising the steps of:

[0032] (1) Preparation of composite powder gel: take 30 parts of dedecyltrimethylphosphorus chloride modified rectorite powder and 20-40 parts of triethylenetetramine modified sepiolite powder and disperse them in 180 parts in N,N-dimethylformamide, and ultrasonically shake at room temperature for 2 hours, then raise the temperature to 75°C, slowly add 30 parts of tetraethyl orthosilicate dropwise, and continue stirring until the solution becomes a solid phase; wash with distilled water Solid phase until the mass remains unchanged, dry at 110°C for 3 hours to obtain a composite powder gel;

[0033](2) Preparation of modified composite adsorbent: Add the modified composite powder gel obtained in step (1) to 15 parts of quaternary ammonium salt tetramer surfactant, 12 parts of chitosan and 80 parts of toluene solvent Mix and stir evenly, then transfer the mixture to a ...

Embodiment 3

[0036] A preparation method of an adsorbent for petrochemical wastewater treatment, comprising the steps of:

[0037] (1) Preparation of composite powder gel: Take 20 parts of cetyltriphenylphosphine chloride modified rectorite powder and 30 parts of ethylenediamine modified sepiolite powder and disperse them in 140 parts of N , in N-dimethylacetamide, and ultrasonically shake at room temperature for 1.5h, then raise the temperature to 70°C, slowly add 25 parts of tetraethyl orthosilicate dropwise, and continue to stir until the solution becomes a solid phase; wash the solid phase with distilled water Phase until the quality remains unchanged, dry at 105°C for 5 hours to obtain a composite powder gel;

[0038] (2) Preparation of modified composite adsorbent: Add the modified composite powder gel obtained in step (1) to 12 parts of quaternary ammonium salt tetramer surfactant, 9 parts of chitosan and 70 parts of toluene solvent Mix and stir evenly, then transfer the mixture to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com