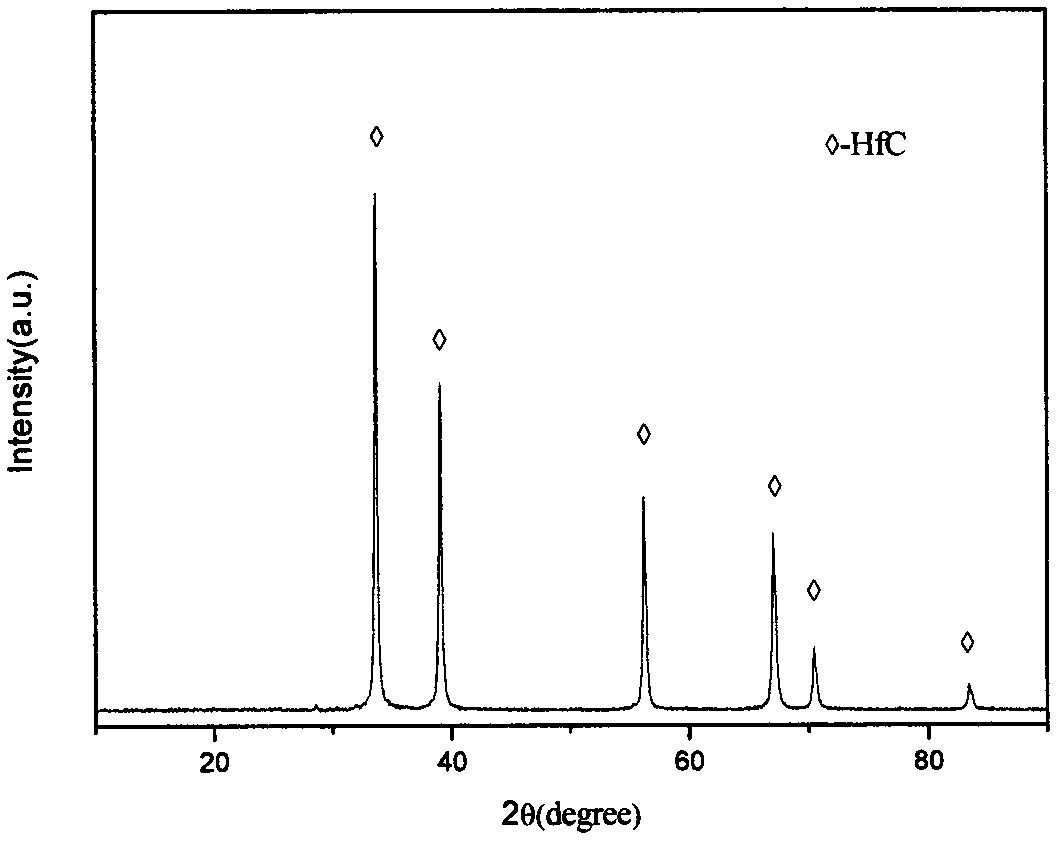

Nano hafnium carbide ceramic organic precursor and preparation method thereof

A technology of organic precursor and hafnium carbide, which is applied in the field of nano-hafnium carbide ceramic organic precursor and its preparation, can solve the problems of complex reaction process route, poor solubility of precursor, long preparation cycle, etc., and achieve cheap and easy raw materials , short preparation cycle and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of nano hafnium carbide ceramic organic precursor, the steps of the preparation method are:

[0025] Step 1. Use a three-necked flask as the main reaction equipment for preparing the organic precursor of hafnium carbide ceramics. One of the ports is used to feed the protective gas argon, the other port is equipped with a constant pressure funnel for adding raw materials, and the third port is connected to reflux After the device is connected to the tail gas treatment device; first vacuumize the three-necked flask to 0.06MPa ~ 0.11MPa, and then pass in argon gas, then repeat vacuuming to 0.06MPa ~ 0.11MPa and pass in argon gas for 2 to 3 times; The argon gas is continuously fed inside as a protective atmosphere;

[0026] Step 2. Under a protective atmosphere, add 1 part of hafnium source to 2.5 to 2.6 parts of acetylacetone, and stir the resulting mixture at room temperature at a rate of 300r / min to 500r / min for 3.5h to 4h, then add 10 to 11 parts o...

Embodiment 2

[0029] A nano hafnium carbide ceramic organic precursor and a preparation method thereof, the steps of the preparation method are:

[0030] Step 1. Use the Schlenk device as the equipment for preparing the organic precursor of hafnium carbide ceramics. First, the Schlenk device is evacuated to 0.07MPa-0.10MPa, and argon is introduced, and then the vacuum is repeatedly evacuated to 0.07MPa-0.10MPa and argon is introduced. 2 to 3 times; then continue to feed argon into the Schlenk apparatus as a protective atmosphere.

[0031]Step 2. Under the argon atmosphere, add 1 part of hafnium source to 2-2.1 parts of acetylacetone, and stir the resulting mixture at room temperature at a rate of 600r / min-900r / min 3h to 3.5h, then add 9 to 10 parts of alcohol, react at 85°C to 90°C for 2.2h to 2.3h, add 3 to 3.1 parts of carbon source, and react at reflux temperature for 2.4h to After 2.5h, an orange transparent solution was obtained. The solvent is removed by a rotary evaporator, and the...

Embodiment 3

[0034] An organic precursor of zirconium carbide ceramics and a preparation method thereof. The steps of the preparation method are:

[0035] Step 1. Use the Schlenk device as the equipment for preparing the organic precursor of hafnium carbide ceramics. First, the Schlenk device is evacuated to 0.083MPa-0.086MPa, and argon gas is introduced, and then the vacuum is repeatedly evacuated to 0.083MPa-0.086MPa and argon gas is introduced. 3 to 4 times; then continue to feed argon into the Schlenk apparatus as a protective atmosphere.

[0036] Step 2. Under the argon atmosphere, add 1 part of hafnium source to 2.1-2.2 parts of acetylacetone, and stir the resulting mixture at room temperature at a rate of 900r / min-1200r / min 2.5h to 3h, then add 7 to 8 parts of alcohol, react at 75°C to 80°C for 2.4h to 2.5h, add 2.5 to 2.6 parts of carbon source. The reaction was carried out at reflux temperature for 2.9h-3h, and an orange transparent solution was obtained. After the solvent is r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com