Preparation method of graphene

A graphene and graphite powder technology, applied in the field of graphene, can solve the problems of difficulty in cleaning and filtering graphene, long reaction time, low production efficiency, etc., and achieve the effects of simple and feasible operation, short preparation time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

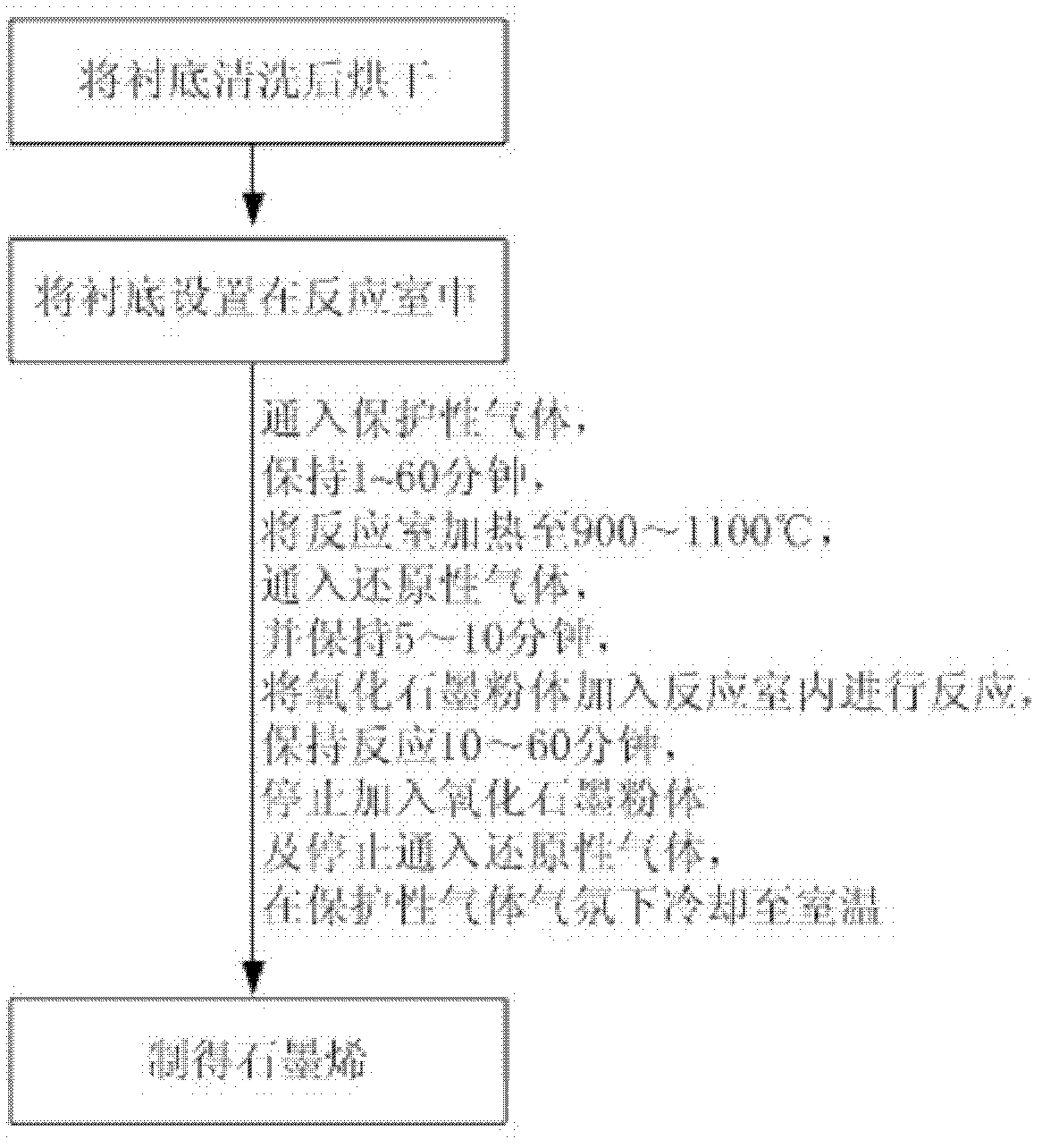

[0024] A kind of preparation method of graphene, such as figure 1 shown, including the following steps:

[0025] (1) drying the metal substrate after cleaning;

[0026] (2) Place the dried substrate in the reaction chamber, and pass a protective gas with a flow rate of 10 to 1000 sccm into the reaction chamber, and keep it for 1 to 60 minutes;

[0027] (3) Subsequently, the reaction chamber is heated to 900-1100°C, and a reducing gas with a gas flow rate of 10-200 sccm is introduced, and the aeration time is kept for 5-10 minutes; then graphite oxide powder is fed at a speed of 1-10 g / min The body is added to the reaction chamber for reaction, and the reaction is maintained for 10 to 60 minutes;

[0028] (4) After the reaction is completed, stop adding the graphite oxide powder and stop feeding the reducing gas, cool to room temperature under a protective gas atmosphere, and prepare graphene on the surface of the substrate.

[0029] In the preparation method of described gr...

Embodiment 1

[0039] A kind of preparation method of graphene, comprises the following steps:

[0040] (1) Carry out ultrasonic cleaning to the stainless steel foil with deionized water, ethanol and acetone respectively, and dry after cleaning;

[0041] (2) The stainless steel foil after drying is arranged in the reaction chamber, and the argon gas with a flow rate of 500 sccm is introduced into the reaction chamber, and kept for 30 minutes;

[0042] (3) The reaction chamber is heated to 1100° C., and the hydrogen gas of 50 sccm is fed into it, and the ventilation time is maintained for 5 minutes; The feed port is put into the reaction chamber for reaction, and the graphite oxide powder enters the reaction chamber after being screened by a 300-mesh copper mesh at the feed port, and the reaction is kept for 20 minutes;

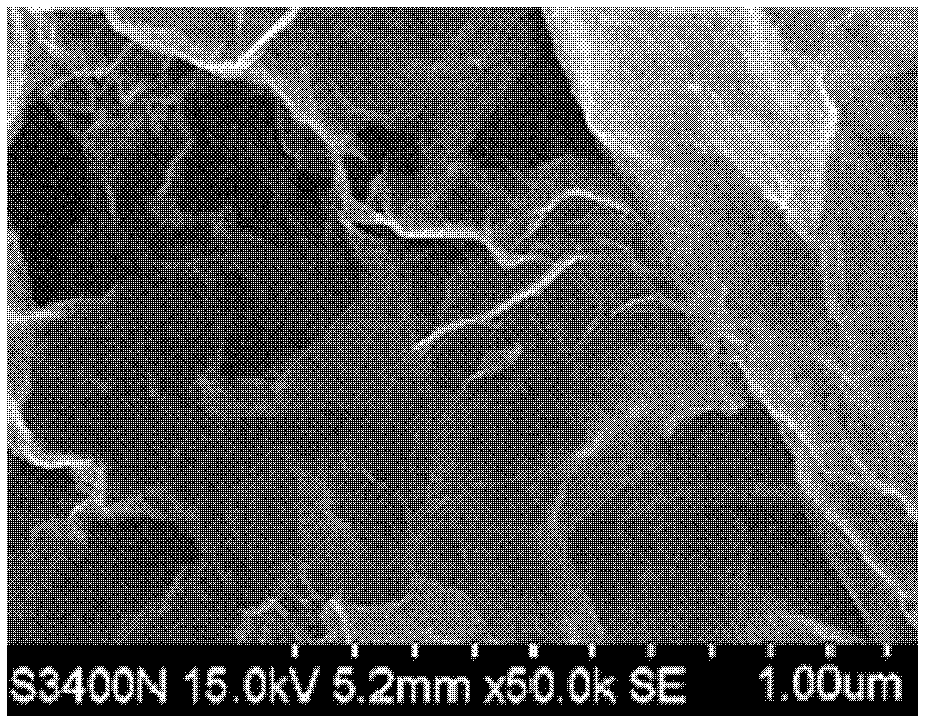

[0043] (4) After the reaction is completed, stop adding graphite oxide powder and stop feeding hydrogen, cool to room temperature under an argon atmosphere, make graphene o...

Embodiment 2

[0046] A kind of preparation method of graphene, and the difference of embodiment one is only: the protective gas in step (1) and step (4) is nitrogen, and the reducing gas that feeds in step (3) is hydrazine vapor, The particle size of graphite oxide powder is 200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com