Fat-free and sugar-free acid milk beverage and preparation method thereof

A milk beverage, sugar acid technology, applied in dairy products, food preparation, whey, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

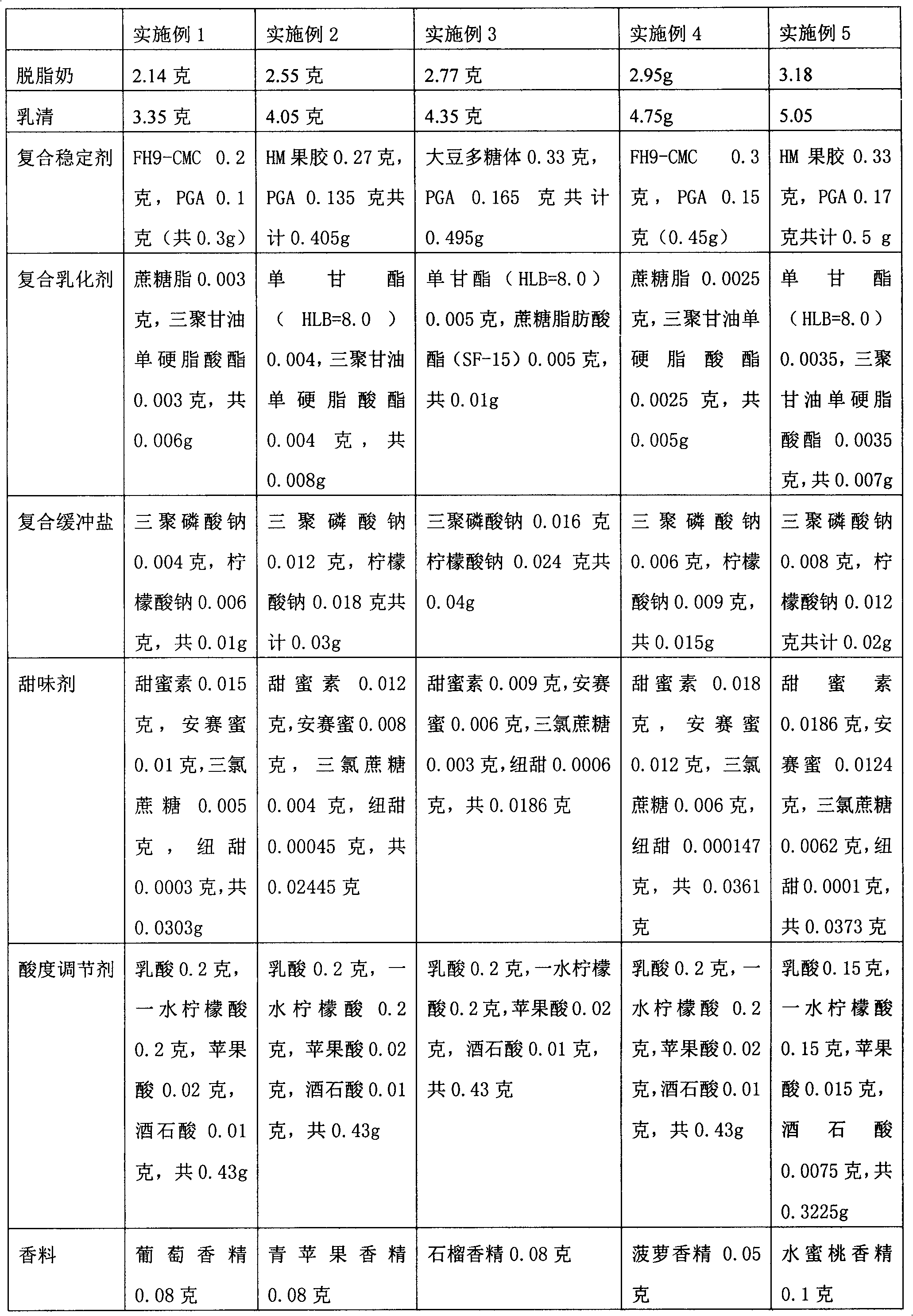

[0061] Example 1: Grape-flavored fat-free sucrose-free yogurt drink

[0062] Formula: (calculated per 100g product)

[0063] Skimmed milk powder 2.14g, non-desalted whey powder 3.35g, FH9-CMC 0.2g, PGA 0.1g, sucrose fat 0.003g, tripolyglycerol monostearate 0.003g, sodium tripolyphosphate 0.004g, sodium citrate 0.006 gram, 0.015 grams of cyclamate, 0.01 grams of acesulfame potassium, 0.005 grams of sucralose, 0.0003 grams of neotame, 0.2 grams of lactic acid, 0.2 grams of citric acid monohydrate, 0.02 grams of malic acid, 0.01 grams of tartaric acid, 0.08 grams of grape essence, add water to 100 grams.

[0064] making process:

[0065] 1) Restoration of skimmed milk powder and whey powder: Add chemical water at 50°C to a sandwich insulation tank, start stirring at a low speed, then add the mixture of skimmed milk powder and whey powder, dissolve and hydrate for 30-40 minutes,

[0066] 2) Preparation of fixed dose: Add chemical water at 70°C to a chemical tank with high-speed...

Embodiment 2

[0071] Example 2: Green Apple flavored fat-free sucrose-free yogurt drink

[0072] Formula: (calculated per 100g product)

[0073] Skimmed milk powder 2.55g, whey powder 4.05g, HM pectin 0.27g, PGA 0.135g, monoglyceride (HLB=8.0) 0.004, tripolyglycerol monostearate 0.004g, sodium tripolyphosphate 0.012g, lemon 0.018g sodium cyclamate, 0.012g cyclamate, 0.008g acesulfame potassium, 0.004g sucralose, 0.00045g neotame, 0.2g lactic acid, 0.2g citric acid monohydrate, 0.02g malic acid, 0.01g tartaric acid, 0.08 apple essence grams, add water to 100 grams.

[0074] Preparation process is identical with embodiment 1 except following parameter:

[0075] In step 1), add 45 ℃ pure water;

[0076] In step 2), add pure water at 75°C;

[0077] In step 3), the homogenization temperature is 50° C., and the homogenization pressure is 100 bar;

[0078] The concentration of the acid solution prepared in step 4 is 5%.

[0079] Product testing index: protein 1.20%, pH: 4.15.

Embodiment 3

[0080] Example 3: Pomegranate fat-free sucrose-free yogurt drink

[0081] Formula: (calculated per 100g product)

[0082] Skim milk powder 2.77g, whey powder 4.35g, soybean polysaccharide 0.33g, PGA 0.165g, monoglyceride (HLB=8.0) 0.005g, sucrose fatty acid ester (SF-15) 0.005g, sodium tripolyphosphate 0.016g , sodium citrate 0.024g, cyclamate 0.009g, acesulfame potassium 0.006g, sucralose 0.003g, neotame 0.0006g, lactic acid 0.2g, citric acid monohydrate 0.2g, malic acid 0.02g, tartaric acid 0.01g, pomegranate Essence 0.08 grams, add water to 100 grams.

[0083] Preparation process is identical with embodiment 1 except following parameter:

[0084] In step 1), add 55 ℃ pure water;

[0085] In step 2), add 72 ℃ pure water;

[0086] In step 3), the homogenization temperature is 60° C., and the homogenization pressure is 90 bar;

[0087] The concentration of the acid solution prepared in step 4 is 4%.

[0088] Product testing indicators: protein 1.30%, pH: 4.20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com