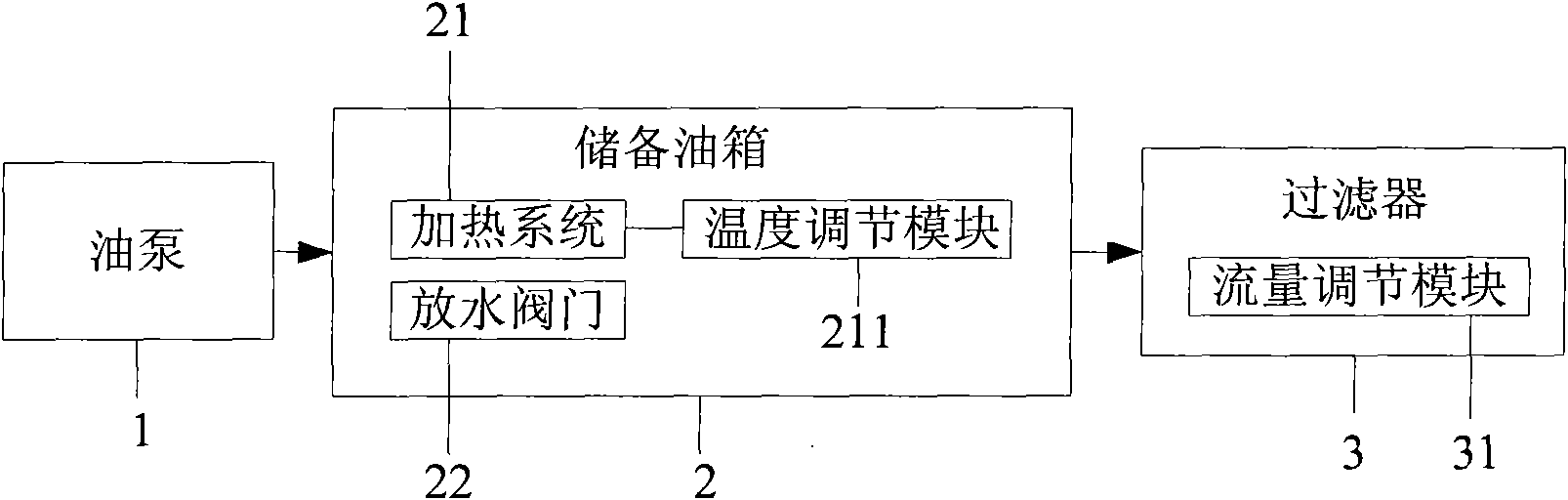

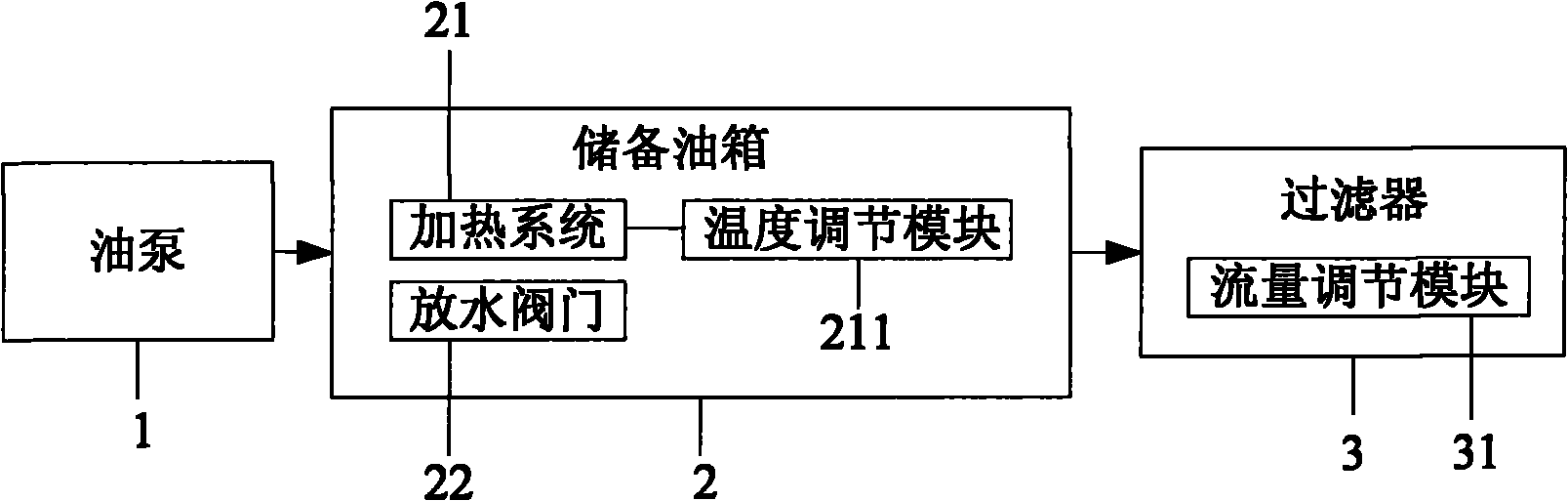

Oil filter device and method

A filter device and filter method technology, applied in the direction of filter separation, separation method, filter circuit, etc., can solve the problems of inability to comprehensively recycle waste oil and achieve the effect of reducing the cost of oil use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Handle the MOBIL533 lubricating oil that has been replaced from the operating system. The oil has a viscosity index of 150, a water content of 0.6%, and an impurity content of NAS15 grade. According to the above indicators of the oil to be treated, use the temperature adjustment module of the heating system to set the heating temperature in the reserve oil tank to 55°C. After the heating in the reserve oil tank and the drainage of the water release valve, the water content of the oil is reduced to 0.1%. Then the oil is subjected to ultra-fine filtration. The filtration process adopts a three-stage filtration method. The first stage uses a 40-mesh metal washable filter element, the second stage uses a 25μ filter element, and the third stage uses a 5μ filter element. The third stage uses a 5μ filter element. The filter element is an ultra-precision filter element with a strong ability to absorb moisture. Because the oil has a high viscosity and contains water, during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com