Direct-acting fine cooling electromagnetic injection valve

A direct-acting, injection valve technology, used in injection devices, injection devices, metal rolling, etc., can solve problems such as inability to timely correct quality, increase equipment failure rates, troublesome debugging and maintenance, etc., to improve production capacity and reduce intermediate links. , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

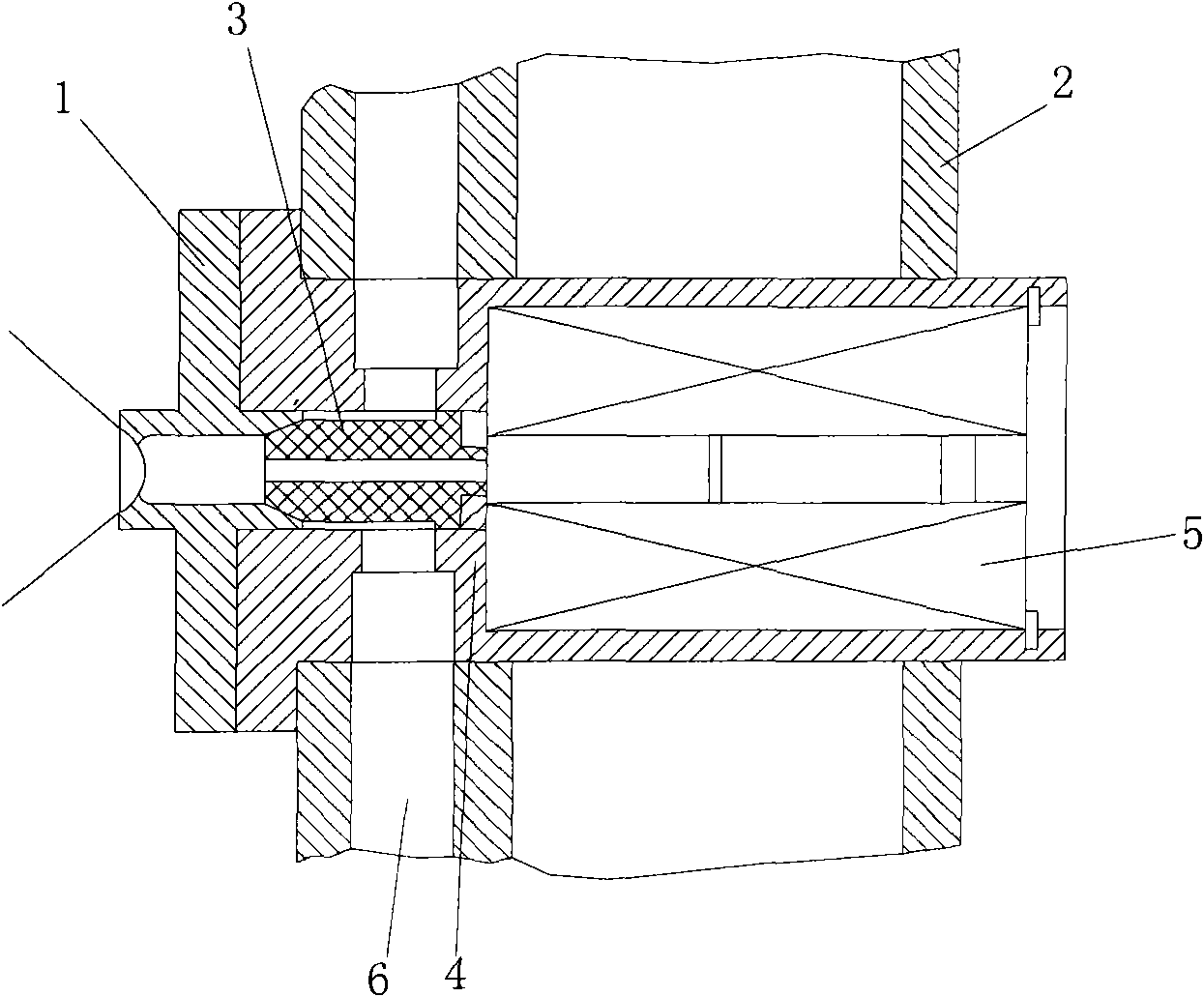

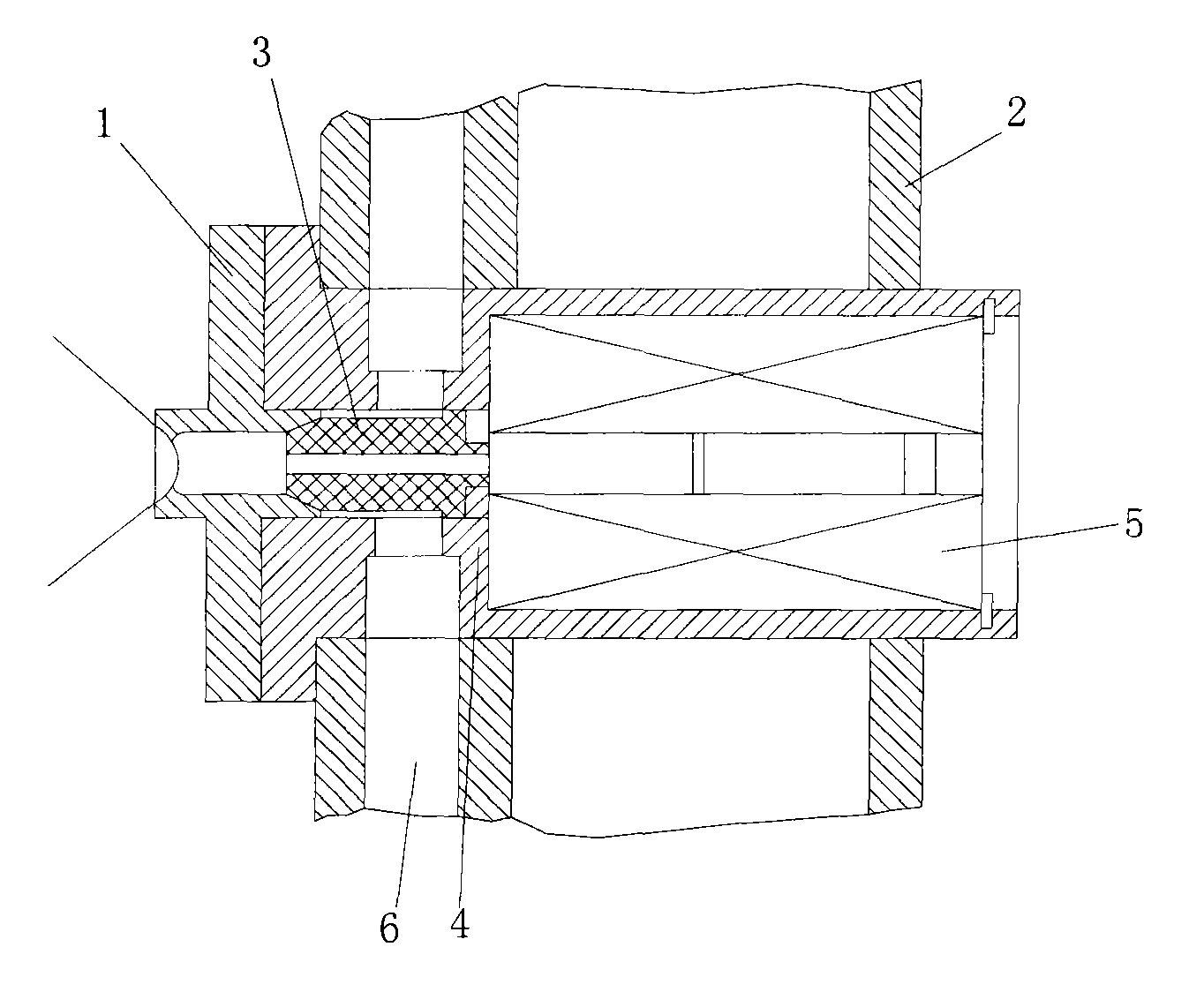

[0019] Such as figure 1 Shown is a schematic structural view of the direct-acting fine cooling electromagnetic injection valve of the present invention, including an injection nozzle assembly 1 , a spray beam 2 , a valve core 3 , a valve body 4 , an electromagnet assembly 5 , and a coolant 6 . The spray nozzle assembly 1 is composed of a spray nozzle body and a spray nozzle. It can choose a suitable nozzle angle and flow rate according to the user's coverage requirements for the cooling of the roll surface. The spray beam 2 is the base organically connected with the rolling mill, which fixes the solenoid valve and provides a sufficient amount of coolant carrier. The spool 3 is made of heat-resistant, corrosion-resistant, and non-deformable imported sealing material, which has the function of opening and closing the cooling liquid output. The valve body 4 is an integr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com