Method for treating industrial wastewater containing hexamethylenediamine

A technology for industrial wastewater and treatment methods, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., can solve problems such as easy harm to the environment, and avoid sludge swelling , the effect of improved biodegradability and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

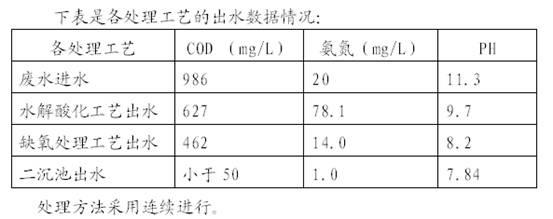

Embodiment 1

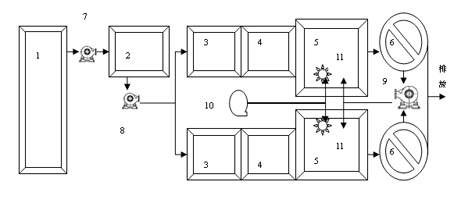

[0041] The treatment method of industrial wastewater containing hexamethylenediamine adopts the A-A-O (anaerobic biological treatment-anoxic-aerobic) treatment process, and combined with the attached drawings, the following steps are carried out in sequence:

[0042] (1) After the industrial wastewater containing hexamethylenediamine is homogenized by the front-end regulating tank 1, it enters the biochemical water treatment system to keep the wastewater load and water volume relatively stable. 11.3, the inlet water temperature is around 35°C.

[0043](2) The wastewater enters the hydrolysis and acidification treatment process, and the water is evenly distributed from the bottom 3 of the pool to ensure that the average residence time is 18 hours. Elastic fillers are evenly distributed in the pool to fix the activated sludge, increasing the contact area between the wastewater and the activated sludge; the submerged mixer is used to prevent a large amount of activated sludge fro...

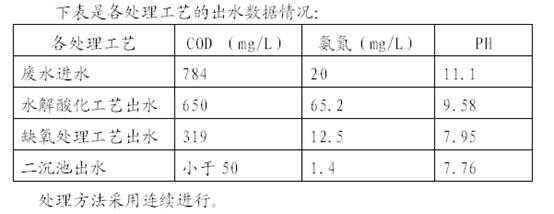

Embodiment 2

[0056] (1) After the industrial wastewater containing hexamethylenediamine is homogenized by the front-end regulating tank 1, it enters the biochemical water treatment system to keep the wastewater load and water volume relatively stable, and control the CODcr of the wastewater inflow at 784 mg / L and the pH value at 11.1, the inlet water temperature is around 30°C.

[0057] (2) The wastewater enters the hydrolysis and acidification treatment process, and the water is evenly distributed from the bottom 3 of the pool to ensure that the average residence time is 17 hours. Elastic fillers are evenly distributed in the pool to fix the activated sludge, increasing the contact area between the wastewater and the activated sludge; the submerged mixer is used to prevent a large amount of activated sludge from depositing and make the water quality uniform to ensure the anaerobic treatment effect. At the same time, part of the sludge return is carried out by the secondary settling tank 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com