Cement asphalt (CA) mortar for polymer cement substrate type ballastless track and preparation method thereof

A technology of emulsified asphalt and ballastless track, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc. The effect of improving the quality of mortar, facilitating construction, and overcoming errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

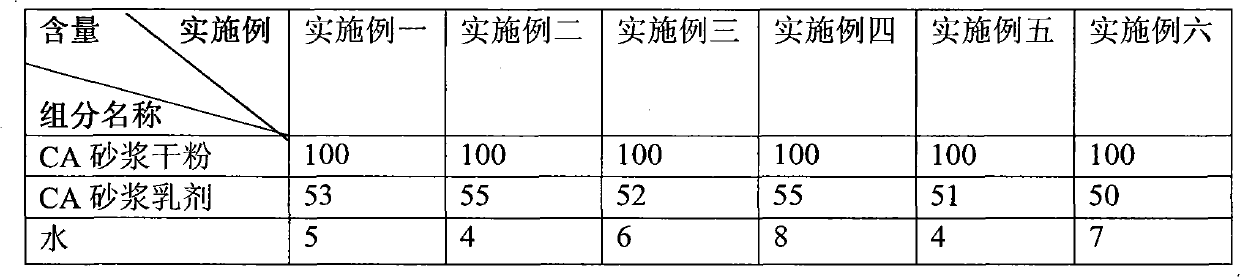

Embodiment 1 Embodiment 6

[0050] An emulsified asphalt mortar for polymer cement substrate type ballastless track, a mixture composed of CA mortar dry powder, CA mortar emulsion and water in the following proportions, the content of each component in the mixture is calculated in parts by weight:

[0051] CA mortar dry powder 100 parts by weight

[0052] CA mortar emulsion 50-55 parts by weight

[0053] 4-8 parts by weight of water

[0054] The above-mentioned dry powder of CA mortar is a mixture (parts by weight) of the following components:

[0055] Cement 0.846 parts

[0056] Expanding agent 0.070 parts

[0057] 0.027 parts of cement accelerator

[0058] Defoamer 0.00053 parts

[0059] Superplasticizer 0.010 parts

[0060] Fine sand 2.183 parts

[0061] The dry powder of CA mortar is a prepared mixture produced in the factory and delivered to the construction site in bags or in bulk.

[0062] The above-mentioned CA mortar emulsion is a composite emulsion composed of anionic emulsified asphalt...

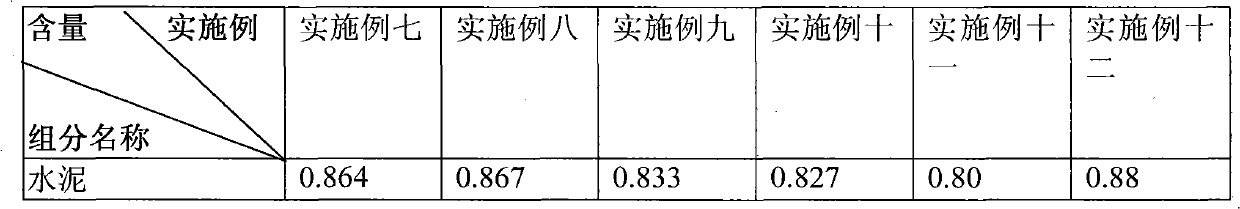

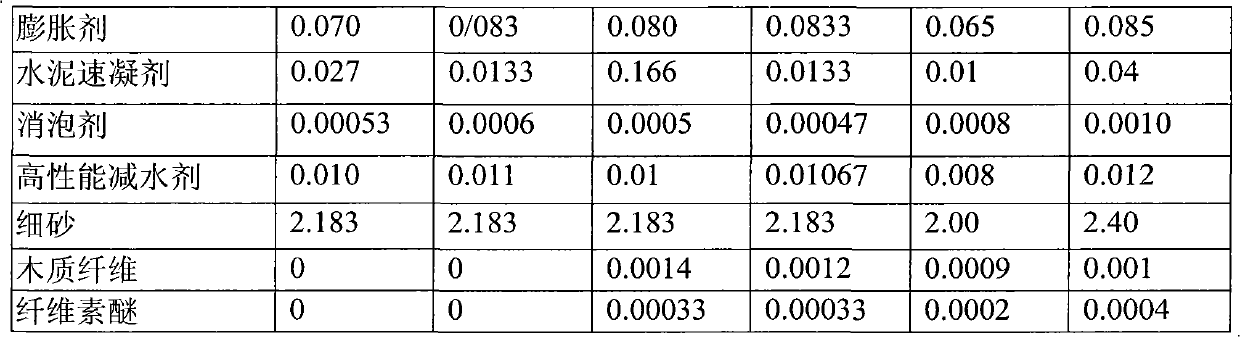

Embodiment 7 Embodiment 12

[0076] The CA mortar dry powder of various proportions in the emulsified asphalt mortar for the polymer cement substrate type ballastless track of the present invention is composed of cement, expansion agent, cement quick-setting agent, defoamer, high-performance water reducer, fine sand , lignocellulose and the mixture that cellulose ether forms, each component content in the mixture of each embodiment is calculated as by mass parts:

[0077] Cement 0.8~0.88 parts

[0078] Expansion agent 0.065~0.085 parts

[0079] Cement quick-setting agent 0.01~0.04 parts

[0080] Defoamer 0.0005~0.0010 parts

[0081] High performance water reducing agent 0.008~0.012 parts

[0082] Fine sand 2.00~2.40 parts

[0083] Lignocellulose 0~0.0014 parts

[0084] Cellulose ether 0~0.0004 part

[0085] In each of the above embodiments, the cement is 425 early-strength ordinary Portland cement. It provides rigidity to the CA mortar and accelerates the CA mortar emulsion from the CA mortar pouri...

Embodiment 19

[0107] The preparation method of emulsified asphalt mortar for polymer cement substrate type ballastless track of the present invention, it comprises the following steps:

[0108] A. Material preparation: According to the total weight of CA mortar to be used, prepare CA mortar dry powder, CA mortar emulsion and water according to the following proportions:

[0109] CA mortar dry powder 100 parts by weight

[0110] CA mortar dry powder 100 parts by weight

[0111] CA mortar emulsion 50-55 parts by weight

[0112] 4-8 parts by weight of water

[0113] B. Put the water and CA mortar emulsion measured in proportion into the mixer at the same time or successively, start the mixer and stir for 3 minutes:

[0114] C. Put the measured CA mortar dry powder into the mixer. The time from the start of feeding to the completion of feeding should not exceed 10 minutes, and stir for 3 to 5 minutes after feeding;

[0115] D. Finished CA mortar inspection: use J-shaped funnel to inspect CA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com