Antistatic polyester

An anti-static and polyester technology, applied in the field of anti-static polyester, can solve the problems of difficult processing, fabric contamination, low dielectric constant and conductivity, etc., and achieve excellent anti-static effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

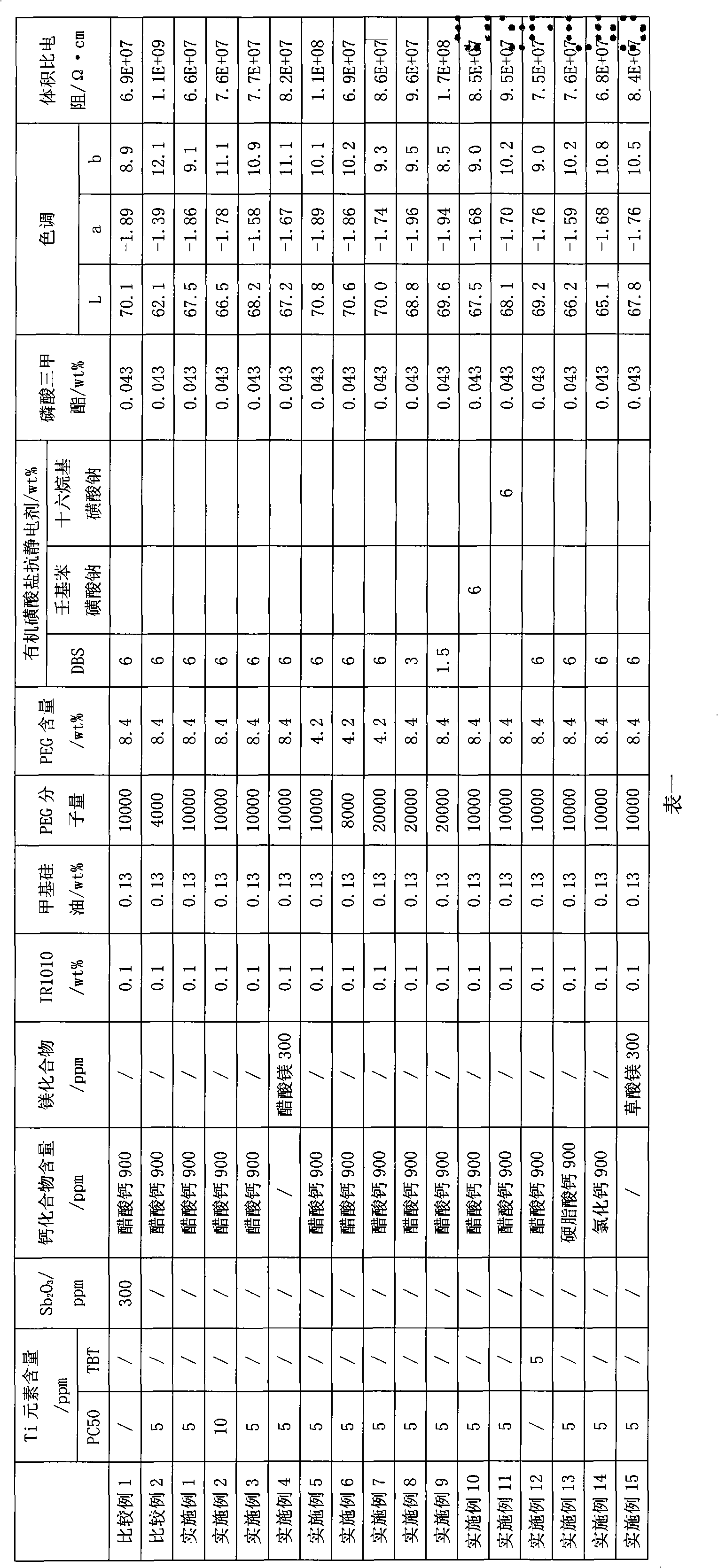

Image

Examples

Embodiment 1

[0020] (1) Transesterification reaction: Add 187 parts (weight) of ethylene glycol and 303 parts (weight) of dimethyl terephthalate (DMT) into the reactor, and add the catalyst at the same time, the amount added (by polymer weight) It is PC-50 (structural formula: The same below), the content of titanium element is 5ppm relative to the weight of polyester, the content of calcium acetate is 900ppm relative to the weight of polyester, the content of antioxidant IR1010 is 0.1wt% relative to the weight of polyester, and the antifoaming agent methyl silicone oil The content is 0.13wt% relative to the weight of the polyester, the final temperature of the esterification is controlled at 240-250°C, and the transesterification reaction is carried out, and the stabilizer trimethyl phosphate, which is 0.043wt% by weight of the polyester, is added to the completion of the transesterification of methanol. Then distill ethylene glycol under normal pressure for 30 minutes, add 6.0 wt% sodiu...

Embodiment 2

[0028] Reaction raw material, reaction condition and device are the same as embodiment 1,

[0029] The addition amount of titanium element in the catalyst PC-50 is 10ppm

[0030] The amount of calcium acetate added is 900ppm

[0031] The addition amount of polyethylene glycol 10000 is 8.4wt%

[0032] The amount of sodium dodecylbenzenesulfonate added is 6wt%.

Embodiment 3

[0034] Reaction raw material, reaction condition and device are the same as embodiment 1,

[0035] The addition amount of titanium element in the catalyst PC-50 is 5ppm

[0036] The amount of calcium acetate added is 500ppm

[0037] The addition amount of polyethylene glycol 10000 is 8.4wt%

[0038] The amount of sodium dodecylbenzenesulfonate added is 6wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com