Magnetron device

A magnetron and magnet technology, which is applied to magnetrons, discharge tubes, transit-time electron tubes, etc., can solve the problem of waste of magnetron sputtering equipment, etc. The effect of increasing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

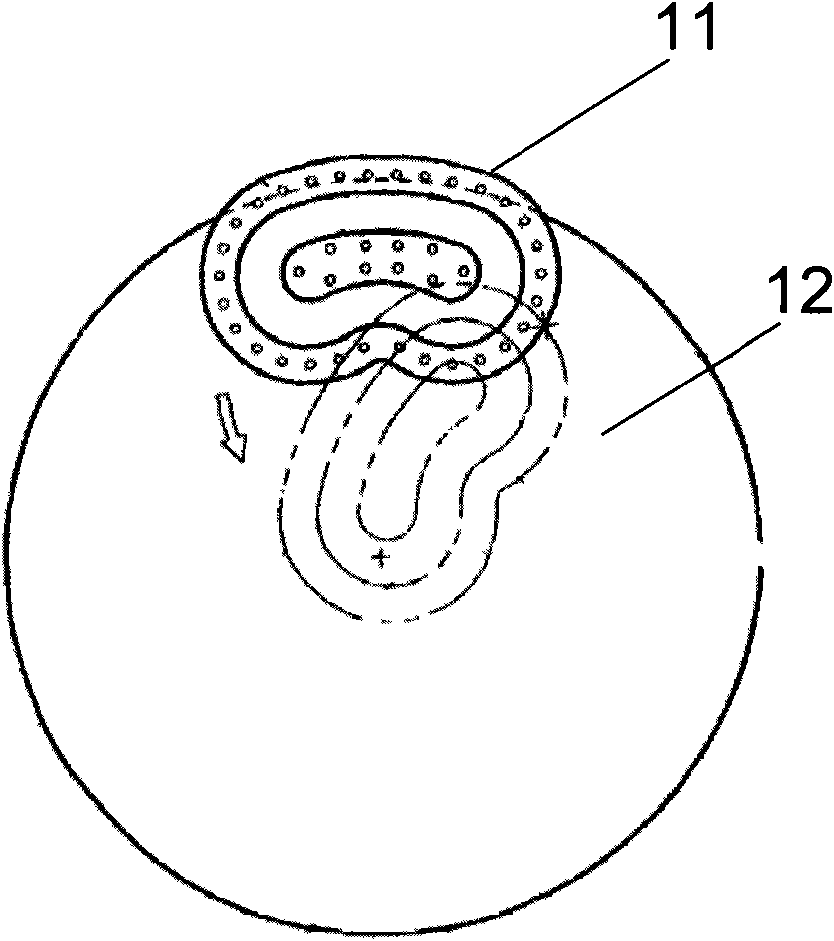

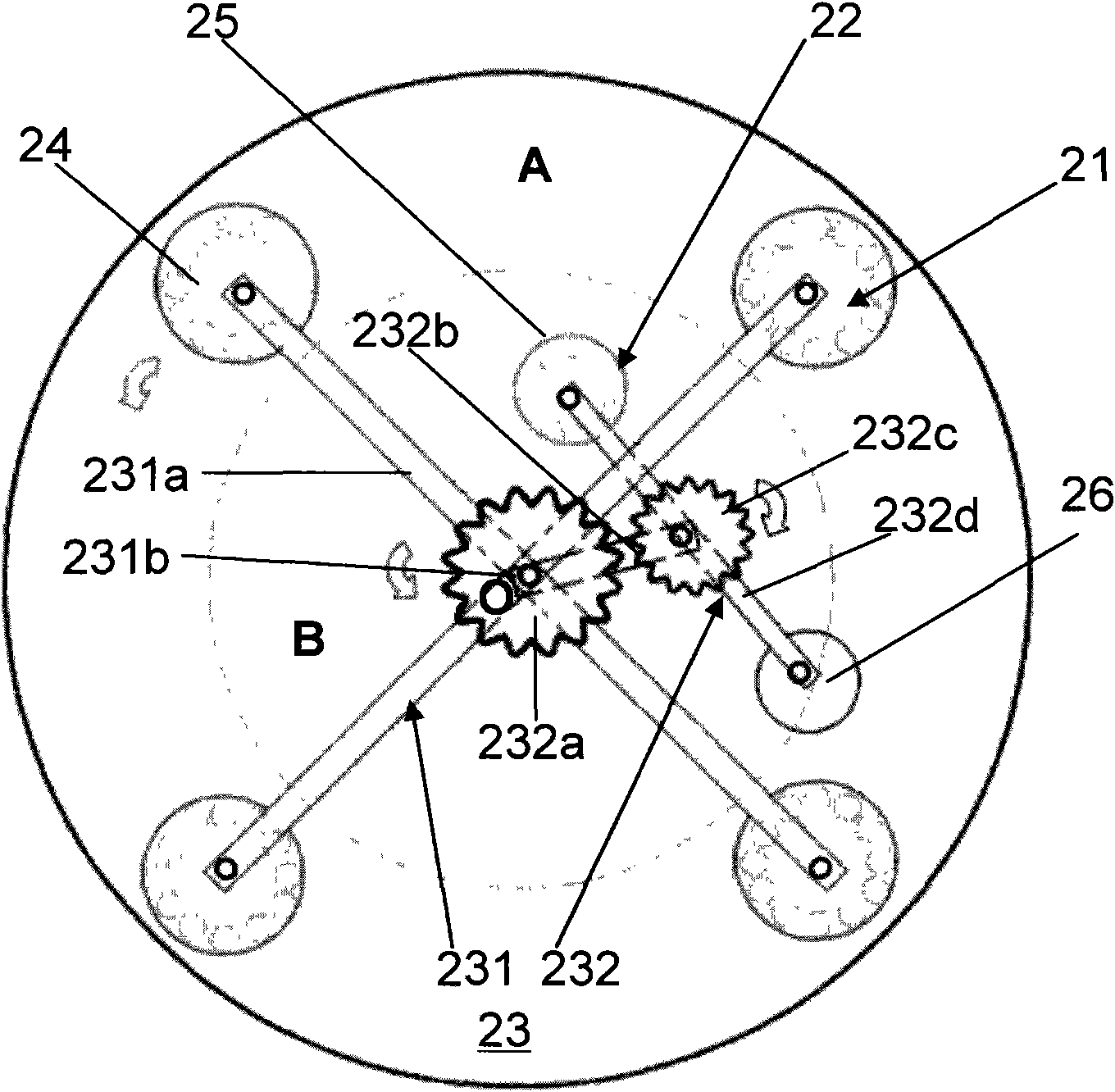

[0041] figure 2 It is a schematic structural diagram of the magnetron device described in this embodiment.

[0042]The magnetron device 20 is arranged on the side of the target material facing away from the vacuum chamber (not shown in the figure), and the target material is a commonly used circular metal target (the circle in the figure indicates the area occupied by the target material). The other side faces the semiconductor wafer to be processed in the vacuum chamber. The circular target includes an outer ring area A and a central area B inside the outer ring area A.

[0043] Such as figure 2 As shown, the magnetron device includes:

[0044] The outer ring area magnetron 21 is located in the outer ring area A;

[0045] The magnetron 22 in the central area is located in the central area B;

[0046] The rotating mechanism 23 is respectively connected with the magnetron 21 in the outer ring area and the magnetron 22 in the central area.

[0047] Wherein, the rotating ...

Embodiment 2

[0060] Figure 5 It is a schematic diagram of the structure of the magnetron device in this embodiment. In order to highlight the characteristics of the invention, the figure does not show the rotation mechanism in the outer ring area.

[0061] As shown in the figure, the difference from Embodiment 1 is that the outer ring area A is divided into two concentric sub-outer ring areas A1 and A2 with unequal radii, then the outer ring of the magnetron device described in this embodiment The zone magnetron 31 includes two corresponding sub-outer zone magnetrons 311 , 312 , wherein the sub-outer zone magnetron 311 is located inside the sub-outer zone magnetron 312 .

[0062] Similar to Embodiment 1, the magnetron in the sub-outer ring area includes at least one magnet group 34, and the magnet group 34 rotates synchronously with the center of the target as the rotating shaft, and the width of the magnet group in the two sub-outer ring area magnetrons The widths of the respective oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com