High-peel-strength nano aluminium plastic composite panel

A high-strength, nano-aluminum technology, applied in the field of decorative materials, can solve the problems of increasing cleaning and maintenance costs of buildings, difficult to meet high-quality requirements, poor acid and alkali resistance on the paint surface, reducing cleaning and maintenance costs, and anti-fouling. Good effect, strong self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

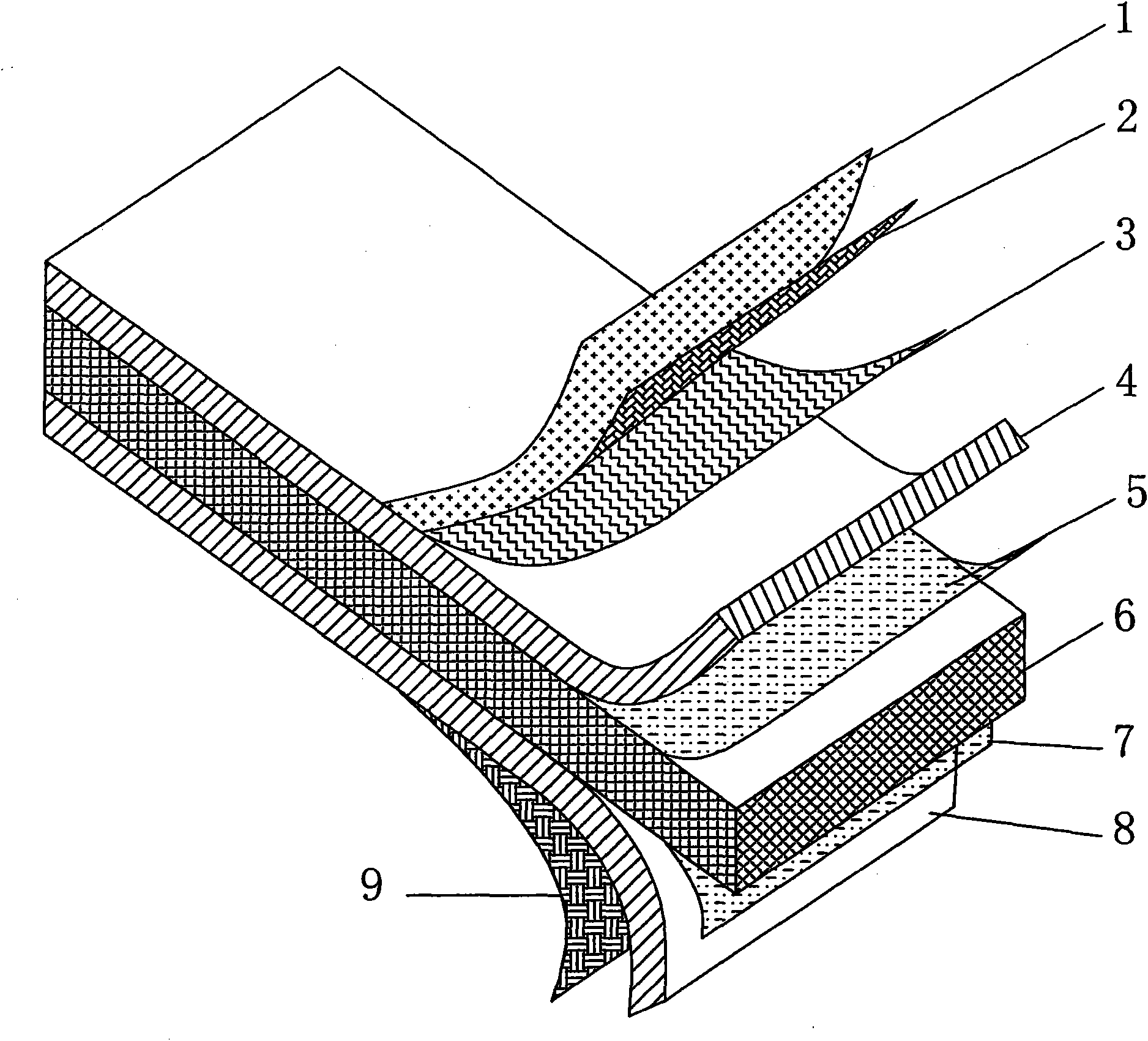

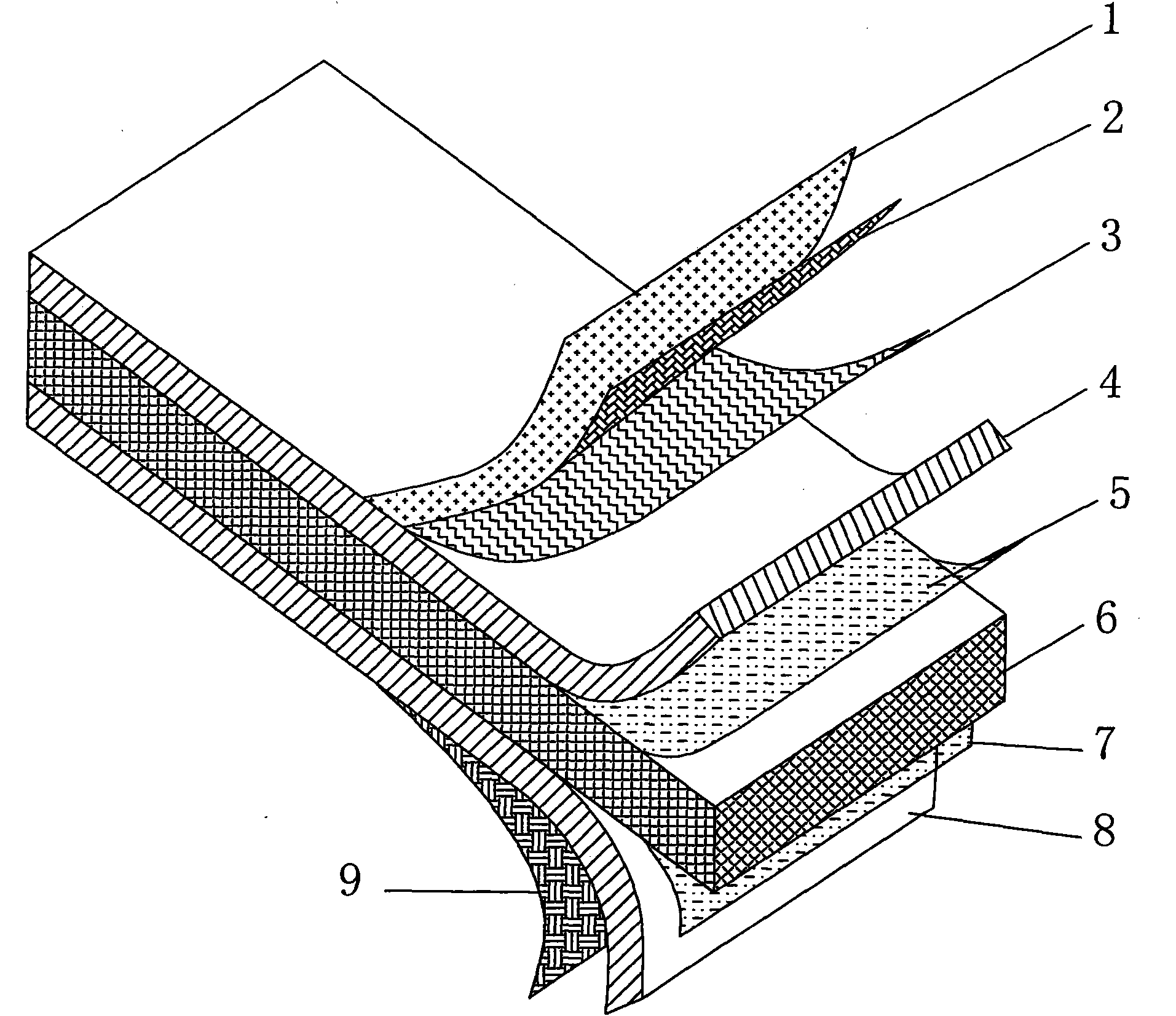

[0018] see figure 1 , the present invention relates to a nano-aluminum-plastic composite board with high peeling strength, the basic aluminum-plastic composite board consists of a front aluminum board 4, an adhesive film layer 5, a plastic layer 6, an adhesive film layer 7 and The back aluminum plate is made of 8 five layers of continuous hot pressing;

[0019] The surface of the front aluminum plate 4 is pre-coated with a base coat 3, and the base coat 3 is rolled with a fluorocarbon coating 2, and the surface of the fluorocarbon coating 2 is provided with a nano-baking varnish surface layer 1;

[0020] The surface of the back aluminum plate 8 is a chemically and treated anti-corrosion light aluminum surface or a pre-rolled anti-corrosion primer 9 .

[0021] The surface of the nano baking varnish surface layer 1 is covered with a peelable protective film.

[0022] The plastic layer 6 is a high-pressure low-density polyethylene layer and can have different thicknesses.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com