Remote monitoring method and system for development machine

A remote monitoring system and remote monitoring technology, applied in electrical program control, earthwork drilling, comprehensive factory control, etc., can solve unfavorable roadheader rapid fault diagnosis, accident handling and remote monitoring management, high labor intensity of drivers, and poor comfort and other issues to achieve the effect of improving safe and reliable operation capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

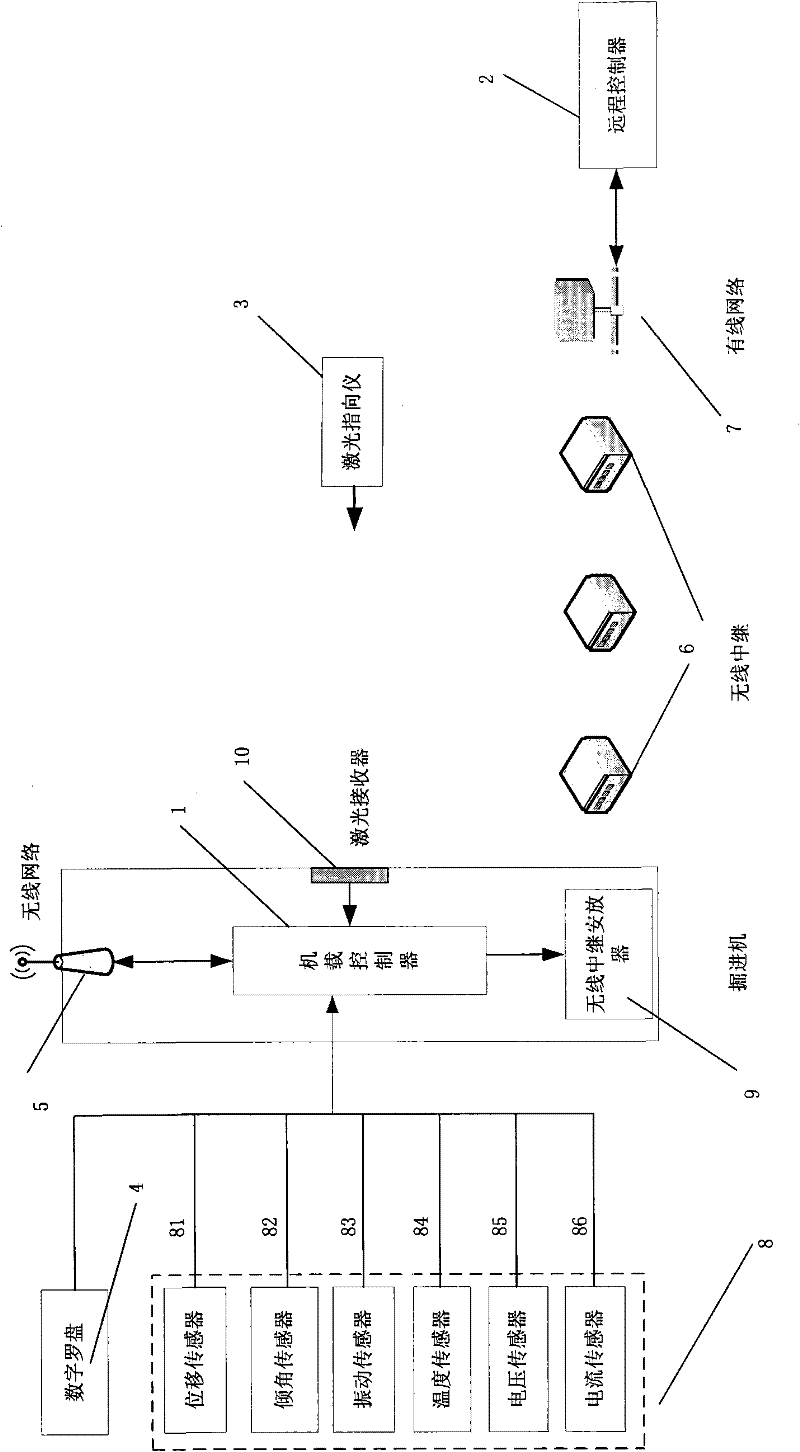

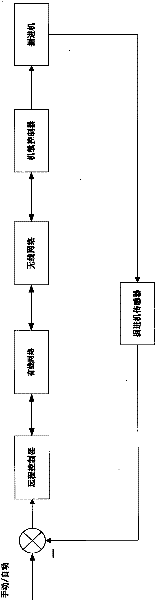

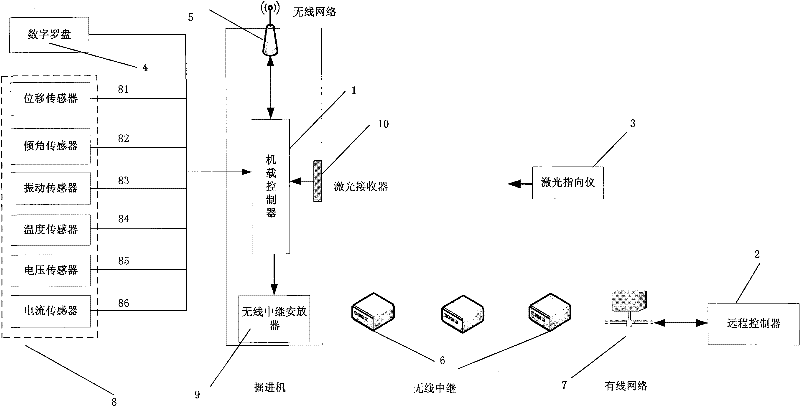

[0015] In order to realize the roadheader remote monitoring method and system of the present invention, it includes: on-board controller, remote controller, laser pointer, digital compass, wireless network, wireless relay, wired network, distributed sensor network, wireless relay Placement device, laser receiver.

[0016] The distributed sensor network is composed of displacement sensors, inclination sensors, temperature sensors, voltage sensors, current sensors and vibration sensors. Monitor the running status of the roadheader comprehensively in real time, and transmit the data to the onboard controller through the field bus; the laser pointing device is used to emit laser beams for precise positioning in the roadway of the roadheader, and is used in pair with the laser receiver ; The laser receiver can capture the light on the laser beam surface, and input the signal to the onboard controller through the field bus; the wireless network can complete the sending and receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com