Preparation method of permanent ferrite

A permanent magnet ferrite and raw material technology, applied in the direction of inorganic material magnetism, etc., can solve the problems of performance gap, unable to meet the growing market, limited output, etc., to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

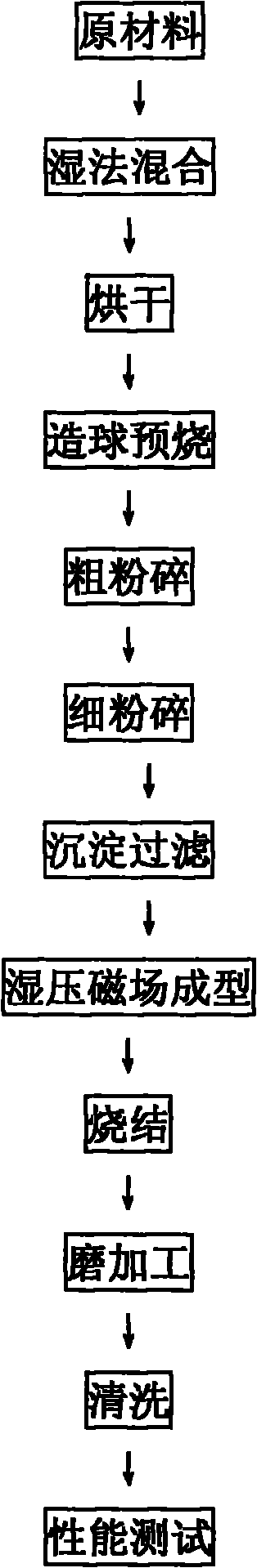

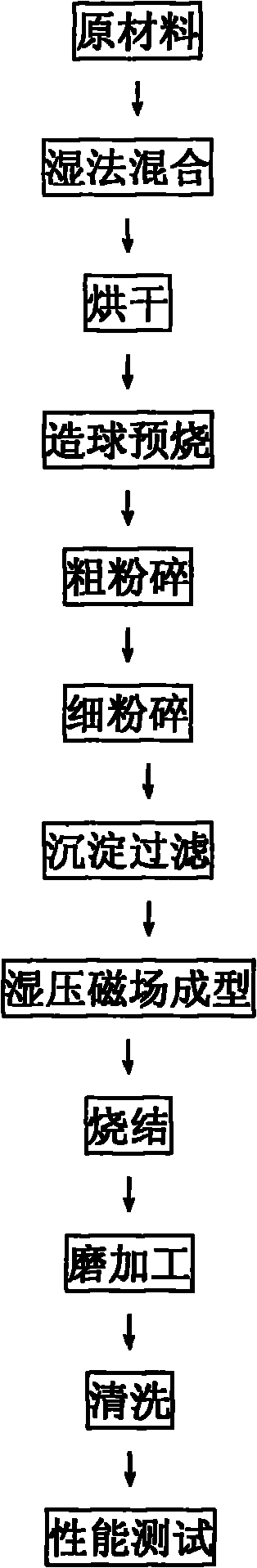

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically described below in conjunction with specific embodiments.

[0031] The preparation method of the permanent magnet ferrite of the present invention is actually an application number of the applicant earlier, the application number is: 200610035683.X; The improvement of the manufacturing method of the invention patent application, its specific method steps are as follows:

[0032] A kind of preparation method of permanent ferrite, it comprises following processing steps,

[0033] Step 1: Select raw materials, including Fe 2 o 3 , SrCO 3 , La 2 o 3 、Co 3 o 4 , CaCO 3 and water, when weighing, press (Sr 1-x La x )O·n{(Fe 1-y co y ) m o 3 Carry out metering, wherein x, m, n, y represent molar ratio, satisfy x=mny, range is as follows: x=0.1~0.4, m=1.93~2.00, n=6.2~6.4; Each raw material is: purity is 98% to 99% Fe 2 o 3 , SrCO with a purity of 96% to 98% 3 , with a Co content of 73% to 74% Co 3 o 4 , with a purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com