Nano porous alloy fuel battery catalyst and preparation method thereof

A nanoporous, fuel cell technology, applied in the fields of nanomaterials and electrochemistry, to achieve the effects of reducing usage, changing reaction paths, and mild preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) 9K (37.5% by weight of gold) commercial gold-silver alloy foil with a length of 1 cm, a width of 1 cm, and a thickness of 100 nm was transferred to 5 mmol / L H 2 PtCl 6 Medium, room temperature (15 ℃) corrosion 10h;

[0033] (2) The corroded sample was washed in ammonia water with a concentration of 14mol / L for 5 minutes to wash away AgCl precipitation;

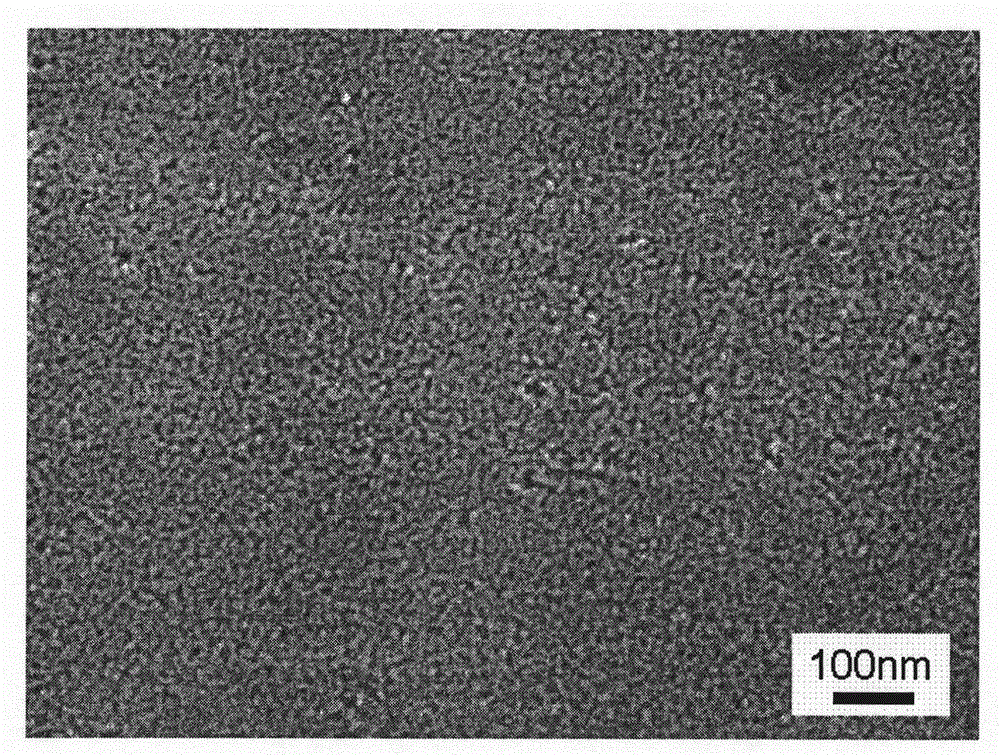

[0034] (3) then be 67% HNO at weight percent concentration 3 Corroded in the solution for 5 minutes, washed with deionized water for 5 times, each time for 5 minutes, a nanoporous platinum alloy fuel cell catalyst was prepared, and its SEM photo is as follows: figure 1 As shown, it shows that the pore size and the thickness of the pore wall are relatively uniform, both in 6-8nm, and the weight percentage of gold in the catalyst is 90%, the weight percentage of platinum is 5%, and the weight percentage of silver is 5%.

Embodiment 2

[0036] (1) 9K commercial gold-silver alloy foil with a length of 2 cm, a width of 2 cm, and a thickness of 100 nm was transferred to 5 mmol / L H 2 PtCl 6 Medium, room temperature (15 ℃) corrosion 10h;

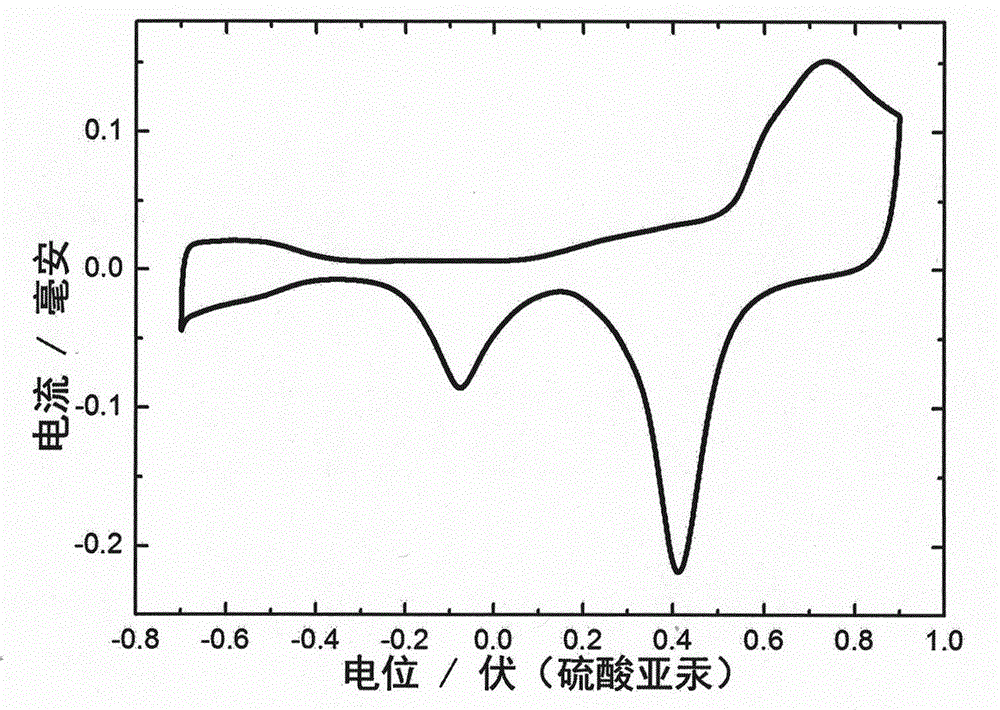

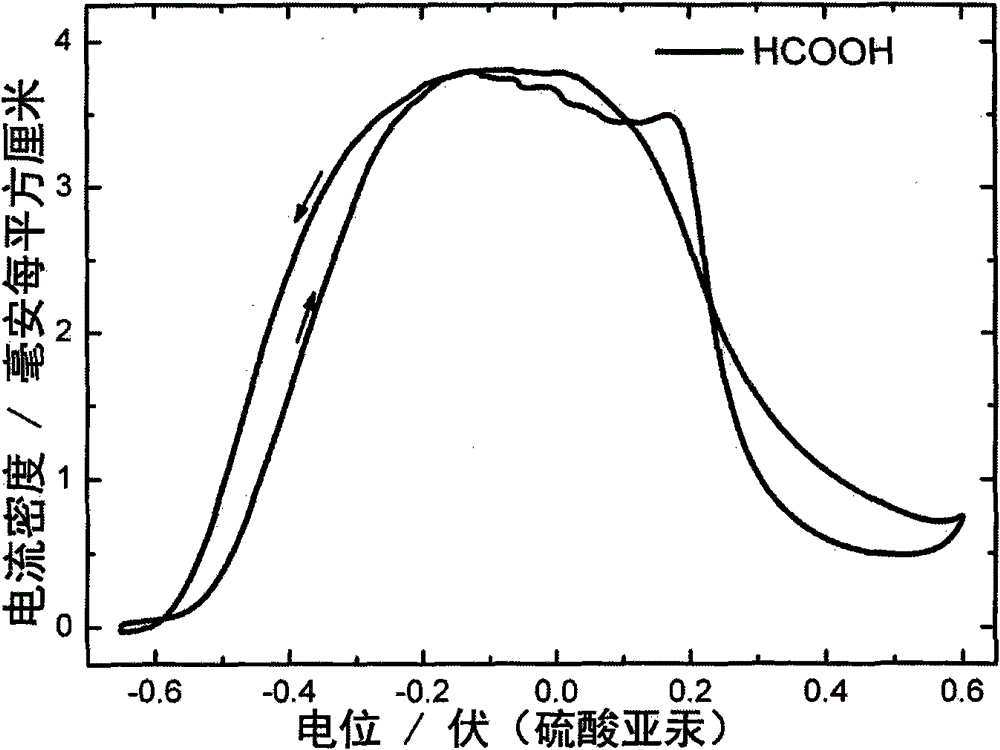

[0037] (2) The corroded sample was washed in ammonia water with a concentration of 14mol / L for 5min to wash away AgCl precipitation, and then washed with deionized water for 5 times, each time for 5min, to prepare a nanoporous platinum alloy fuel cell catalyst, and its cyclic voltammetry curve Such as figure 2 , 3 , 4, and 5. SEM photographs show that the pore size and pore wall thickness are relatively uniform, both in the range of 6-8nm. The weight percentage of gold in the catalyst is 87%, the weight percentage of silver is 7%, and the weight percentage of platinum is 6%.

Embodiment 3

[0039] (1) 9K commercial gold-silver alloy foil with a length of 2cm, a width of 2cm, and a thickness of 100nm was transferred to 10mmol / L H 2 PtCl 6 medium, 30°C corrosion for 2h;

[0040] (2) The corroded sample was washed in ammonia water with a concentration of 10mol / L for 10min to wash away AgCl precipitation;

[0041] (3) then in weight percent concentration be 55% HNO 3 Corroded in the solution for 10 minutes, washed with deionized water for 8 times, each time for 8 minutes, to prepare a nanoporous platinum alloy fuel cell catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com