Device for electrochemically preparing hydrogen peroxide with zero gap between electrode and diaphragm and its application method

A hydrogen peroxide, zero-spacing technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of increased catalyst surface mass transfer resistance, slow oxygen mass transfer, unfavorable control, etc., to avoid the difficulty of reaction gas mass transfer. , the effect of stable operation and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

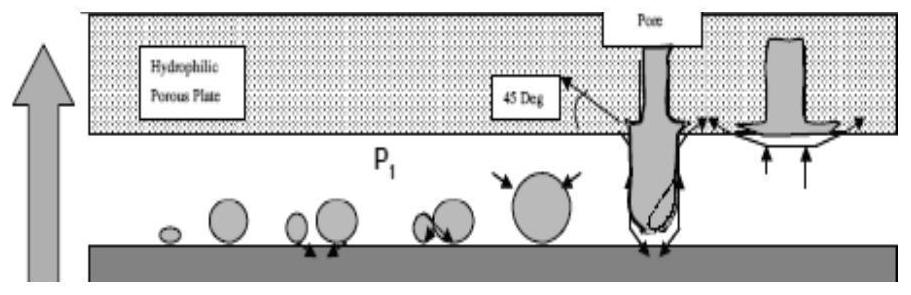

Method used

Image

Examples

Embodiment 1

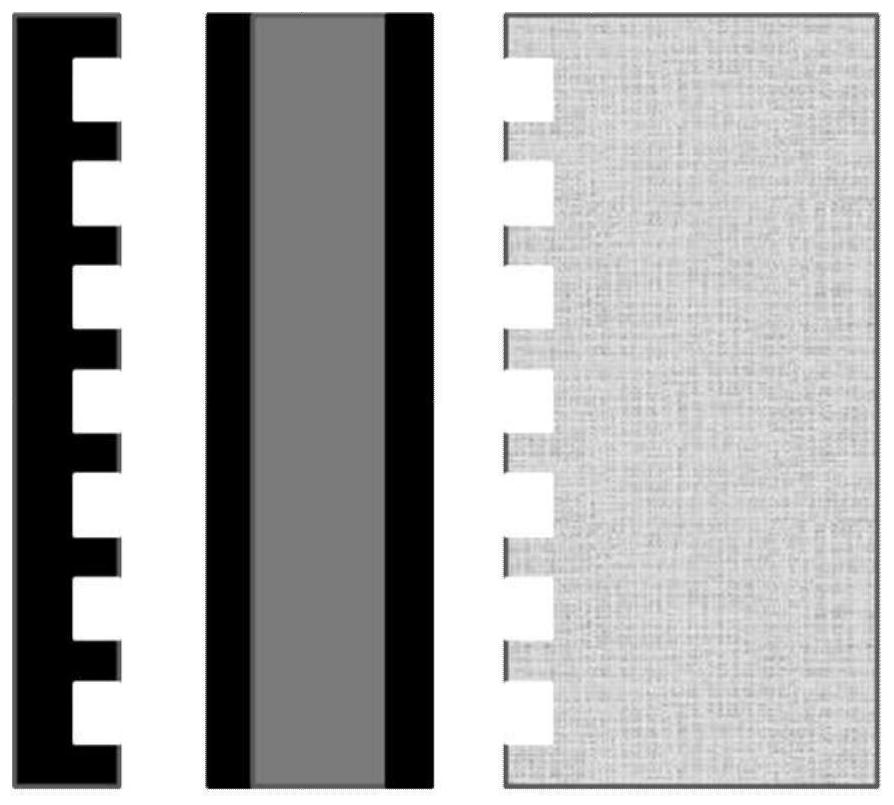

[0021] The anode of embodiment 1, hydrogen peroxide generator is used to be loaded with the gas diffusion electrode of Pt / C catalyst, diaphragm adopts naphthol film N212, and cathode adopts the gas diffusion electrode that is loaded with XC-72R carbon powder catalyst, in this electrode The PTFE content is 5%. Connected with the cathode is nickel foam with a thickness of 2mm, a porosity of 30%, an average pore diameter of 0.5mm, and polyvinyl alcohol in the pores as a hydrophilic agent. A straight gas flow field with a depth of 0.4 mm is engraved on the side where the nickel foam is connected to the electrode.

Embodiment 2

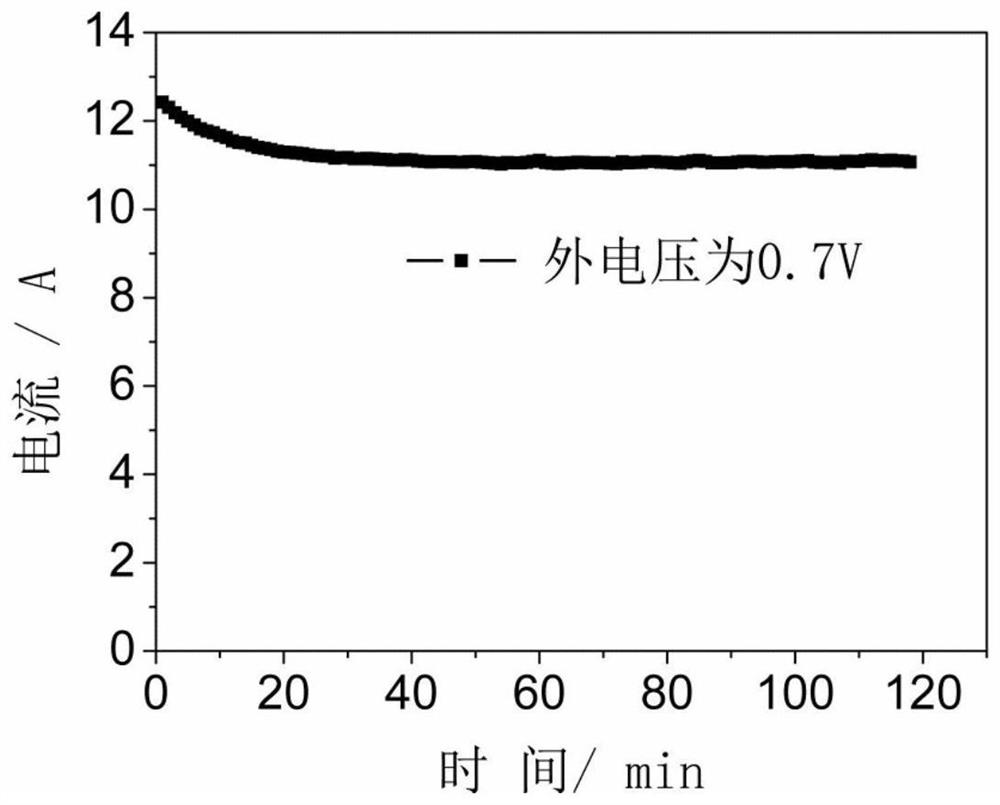

[0022] The anode of embodiment 2, hydrogen peroxide generator is used to be loaded with the gas diffusion electrode of PtRu / C catalyst, diaphragm adopts naphthol film N115, and cathode adopts the gas diffusion electrode that is loaded with BP-2000 carbon powder catalyst, in this electrode The PTFE content is 60%. Connected to the cathode is a porous graphite plate with a thickness of 1 cm, a porosity of 60%, an average pore diameter of 0.2 mm, and silicon dioxide as a hydrophilic agent in the pores. The side of the porous graphite plate connected to the electrode has a serpentine gas flow field with a depth of 1 mm. The anode of the battery is fed with hydrogen, and the cathode is fed with oxygen. The anode is connected to the positive pole of the external power supply, the cathode is connected to the negative pole of the external power supply, and the voltage of the external power supply is set to 0.7V. The current-time curve during battery operation is shown in image 3 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com