A method for preparing nickel-cobalt oxygen and sulfur compound composite film electrodes

A technology of sulfur compounds and composite films, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors to achieve the effects of small electrode internal resistance, excellent corrosion resistance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing nickel-cobalt oxygen and sulfur compound thin-film electrodes. Firstly, pure iron foil is selected as the current collector substrate, and the current collector substrate with a size of 20 mm×10 mm×0.2 mm is degreased, washed, pickled and washed with water. , and then chemically plated in an alkaline nickel-cobalt-phosphorus plating solution at (82±1)°C for 30 minutes to prepare a current collector with a nickel-cobalt-phosphorus alloy coating on the surface. Energy spectrum analysis shows that Ni, Co The mass fractions of and P were 45.99%, 46.01% and 8.00%, respectively. After washing and drying the current collector, soak it in supersaturated sodium sulfide solution for 1 minute, take it out and place it in a box-type resistance furnace at 330°C for high-temperature oxidation and vulcanization for 1 hour. After taking it out and cooling it, you can get nickel-cobalt oxygen and sulfur Compound composite thin film electrodes.

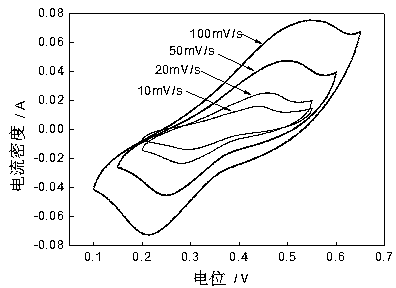

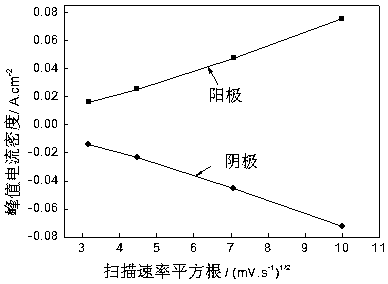

[0028] as attache...

Embodiment 2

[0032] A method for preparing a nickel-cobalt oxygen-sulfur compound thin-film electrode. First, copper foil is selected as a current collector substrate, and the current collector substrate with a size of 20 mm×10 mm×0.2 mm is degreased, washed with water, pickled, and washed with water. Then electroless plating in an alkaline nickel-cobalt-phosphorus plating solution at (82±1)°C for 120 minutes to prepare a current collector with a nickel-cobalt-phosphorus alloy coating on the surface. After washing and drying the current collector, soak it in supersaturated sodium sulfide solution for 2 minutes, take it out and place it in a box-type resistance furnace at 420°C for high-temperature oxidation and vulcanization for 2 hours. After taking it out and cooling it, you can get nickel-cobalt oxygen and sulfur Compound composite thin film electrodes.

[0033] as attached Figure 4 As shown, the PARSTAT2273 electrochemical workstation was used, the Hg / HgO electrode was used as the re...

Embodiment 3

[0037] A method for preparing nickel-cobalt oxygen and sulfur compound thin-film electrodes. Firstly, pure iron foil is selected as the current collector substrate, and the current collector substrate with a size of 20 mm×10 mm×0.2 mm is degreased, washed, pickled and washed with water. , and then electroless plating in an alkaline nickel-cobalt-phosphorus plating solution at (82±1)°C for 80 minutes to prepare a current collector with a nickel-cobalt-phosphorus coating on the surface. After washing and drying the current collector, soak it in a supersaturated sodium sulfide solution for 1 minute, take it out and place it in a box-type resistance furnace at 100, 190, 300, 350, 400 and 450°C for high-temperature oxidation and vulcanization for 1 hour. After taking out and cooling, the nickel-cobalt oxygen-sulfur compound composite film electrode is obtained.

[0038] as attached Figure 7 As shown, the PARSTAT2273 electrochemical workstation was used, the Hg / HgO electrode was u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com