a cs 2 agbibr 6 Double perovskite and its preparation method

A double perovskite and anti-solvent technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of impure synthetic products, low synthetic efficiency, and strong corrosion of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

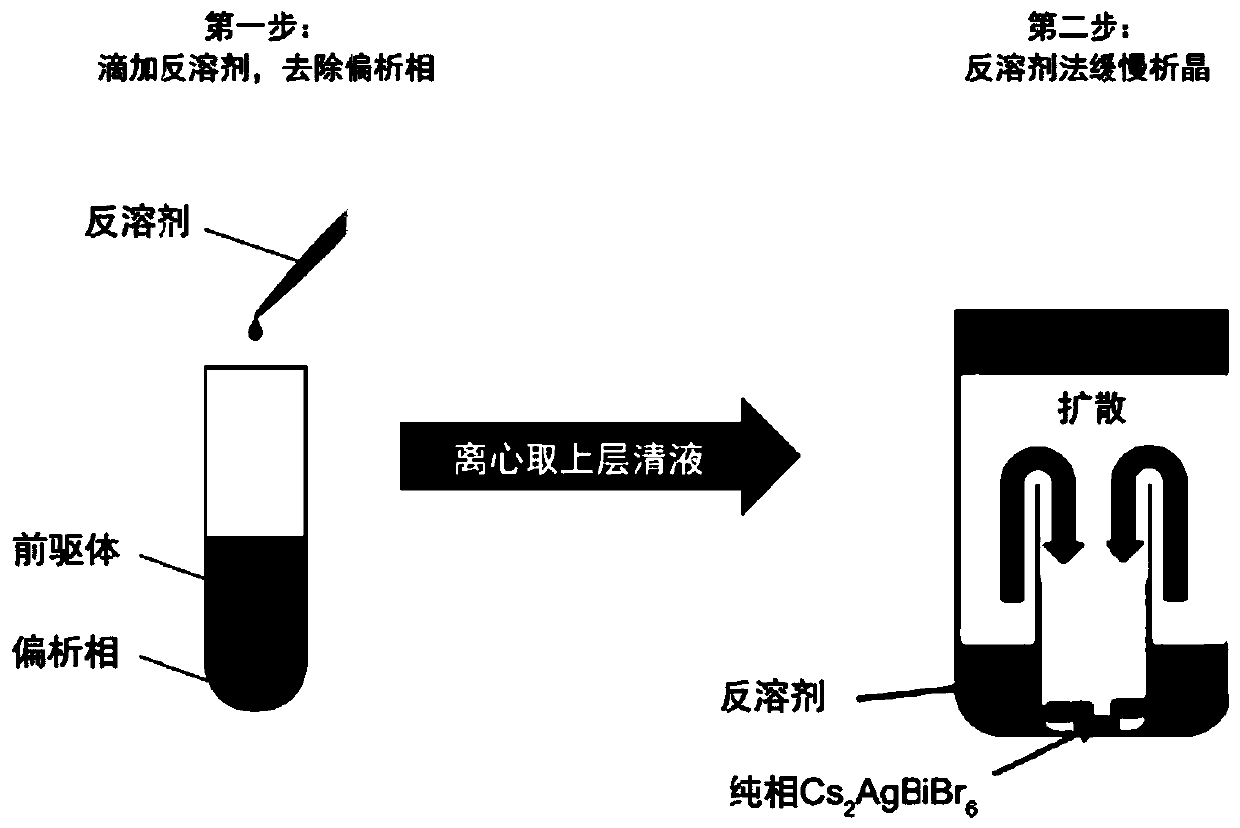

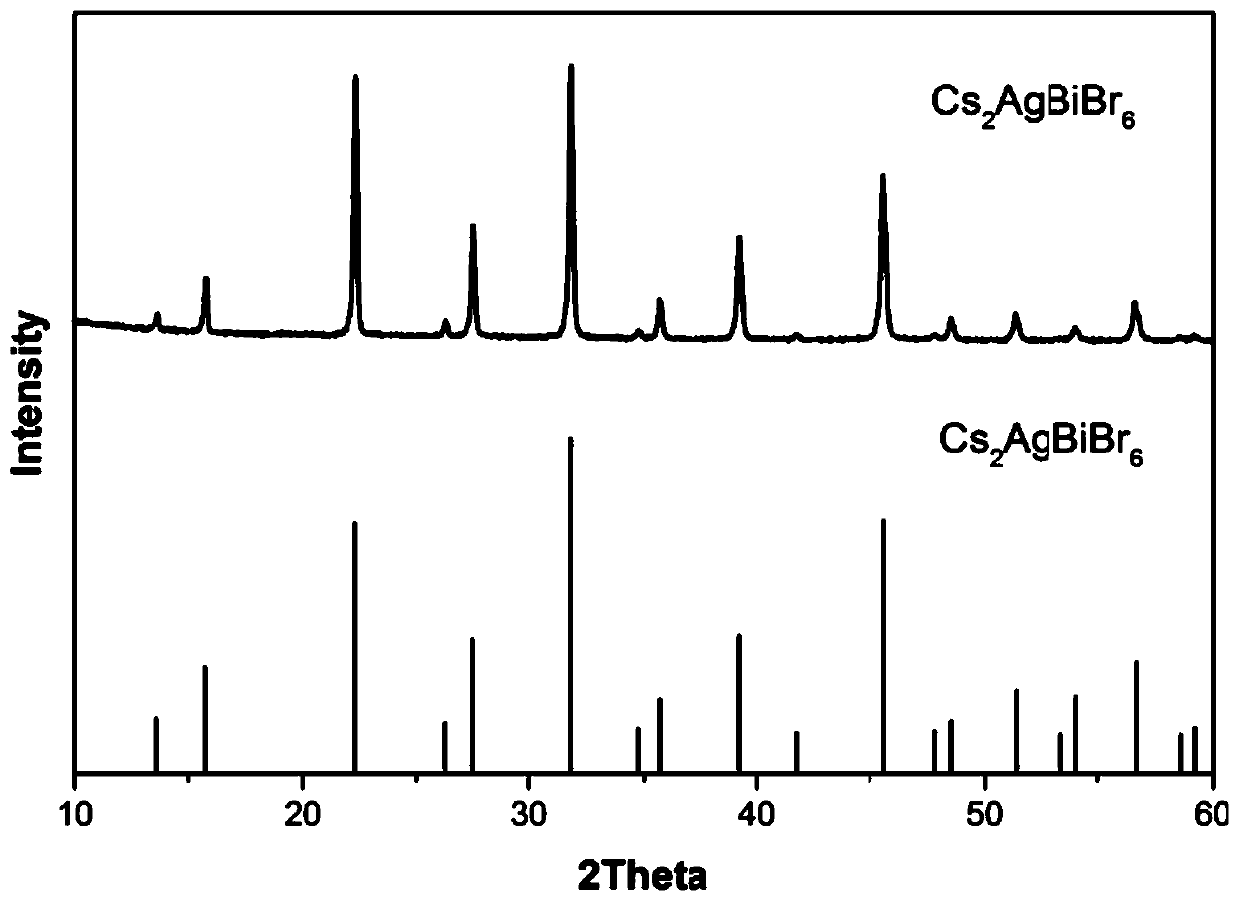

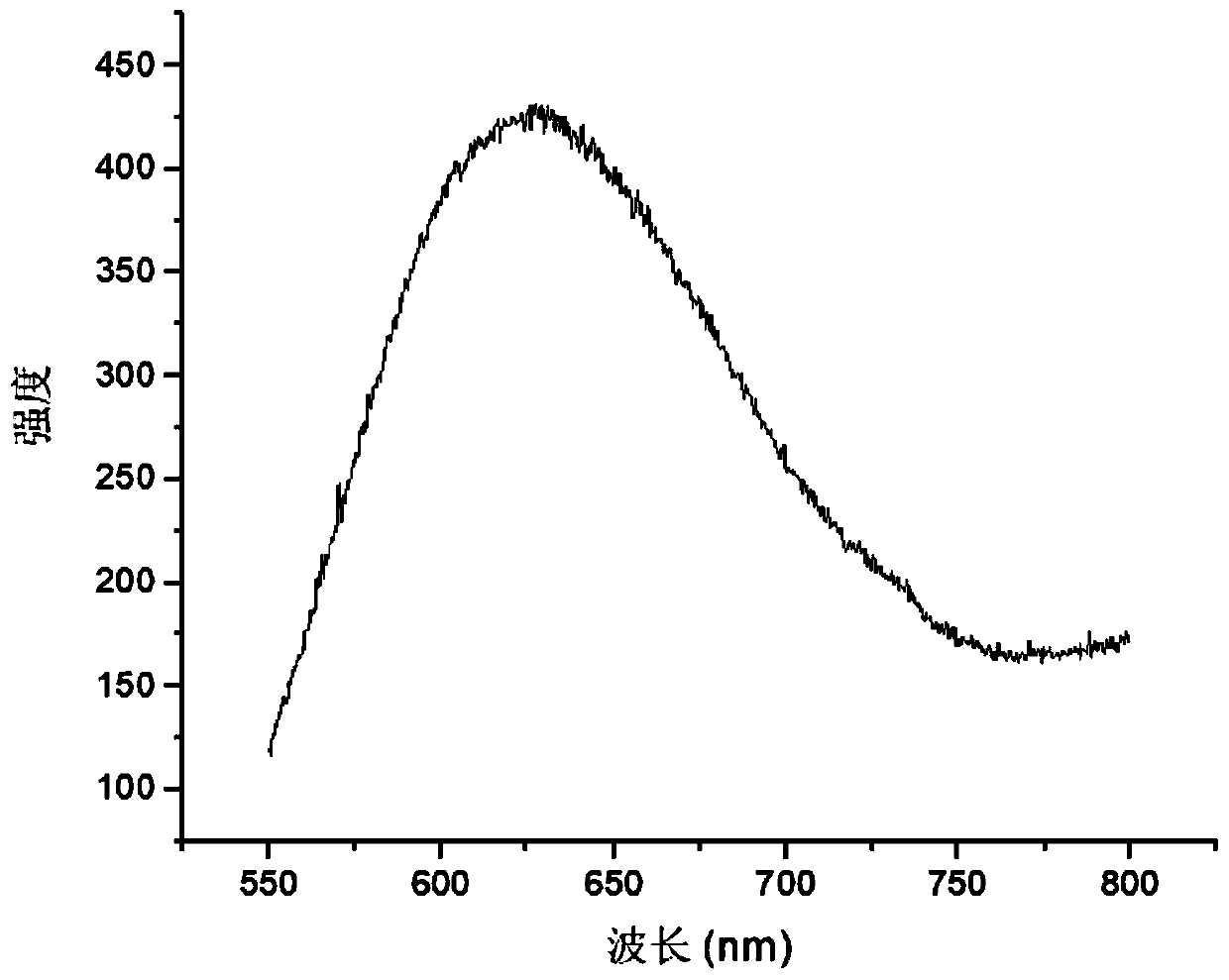

[0029] Such as figure 1 As shown, a Cs 2 AgBr 6 The preparation method of double perovskite, comprising:

[0030] (1) After mixing cesium bromide, silver bromide and bismuth tribromide according to the molar ratio of 2:1:X, they are dissolved in an organic solvent, the temperature during dissolution is 50°C-70°C, and the organic solvent is DMF, DMSO or Mix the solution in any ratio to obtain the precursor solution;

[0031](2) Add anti-solvent dropwise to the precursor solution. The anti-solvent is dichloromethane, chlorobenzene or turpentine permeate alcohol, and the solution precipitates a white precipitate, so that the volume ratio of the precursor solution and the anti-solvent is 1: Y, and the segregation crystals are removed. (white precipitate), at this moment, orange color appeared in the precipitate, and the dropwise addition was stopped immediately to obtain a solid-liquid mixture;

[0032] (3) After the solid-liquid mixture is centrifuged, get the supernatant liq...

Embodiment 1

[0036] a Cs 2 AgBr 6 The preparation method of double perovskite, comprising:

[0037] 1. Weigh 0.212g CsBr, 0.0939g AgBr and 0.224g BiBr 3 (molar ratio is 2:1:1), dissolved in 5ml of DMF, heated and stirred at 60°C for about 2 hours to obtain 0.1mol / L CABB precursor solution.

[0038] 2. Wash the glass bottles and centrifuge tubes with deionized water solution of detergent, acetone, isopropanol and ethanol for 10 minutes, and dry them in an oven.

[0039] 3. Take 5ml of precursor solution in a centrifuge tube, and then take 10ml of dichloromethane (the volume ratio of precursor to anti-solvent is 1:2).

[0040] 4. Add dichloromethane dropwise to the precursor solution, shake while dropping, and the solution precipitates a white precipitate. After continuous dropwise addition to 10ml of dichloromethane, the precipitate appeared orange, and the dropwise addition was stopped immediately.

[0041] 5. Centrifuge at 3000 rpm for 5 minutes, take the supernatant and put it into ...

Embodiment 2

[0046] a Cs 2 AgBr 6 The preparation method of double perovskite, comprising:

[0047] 1. Weigh 0.212g CsBr, 0.0939g AgBr and 0.448g BiBr 3 (molar ratio is 2:1:2), dissolved in 5ml of DMF and DMSO 1:1 mixed solvent, heated and stirred at 50°C for about 2h to obtain a CABB precursor solution.

[0048] 2. Wash the glass bottles and centrifuge tubes with deionized water solution of detergent, acetone, isopropanol and ethanol for 10 minutes, and dry them in an oven.

[0049] 3. Take 5ml of precursor solution in a centrifuge tube, and then take 7ml of chlorobenzene (the volume ratio of precursor to anti-solvent is 1:1.4).

[0050] 4. Add chlorobenzene dropwise to the precursor solution, oscillate while dropping, and the solution precipitates a white precipitate. After continuous dropwise addition to 7ml of chlorobenzene, the precipitate appeared orange, and the dropwise addition was stopped immediately.

[0051] 5. Centrifuge at 3000 rpm for 5 minutes, take the supernatant and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com