A high-hardness single-phase high-entropy alloy coating and its preparation method and use

A high-entropy alloy and high-hardness technology, which is applied in the coating process of metal materials, coatings, mechanical equipment, etc., can solve the problems of harsh preparation process requirements and large-scale promotion and use, and achieve simple process and electrochemical corrosion resistance Excellent, high hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

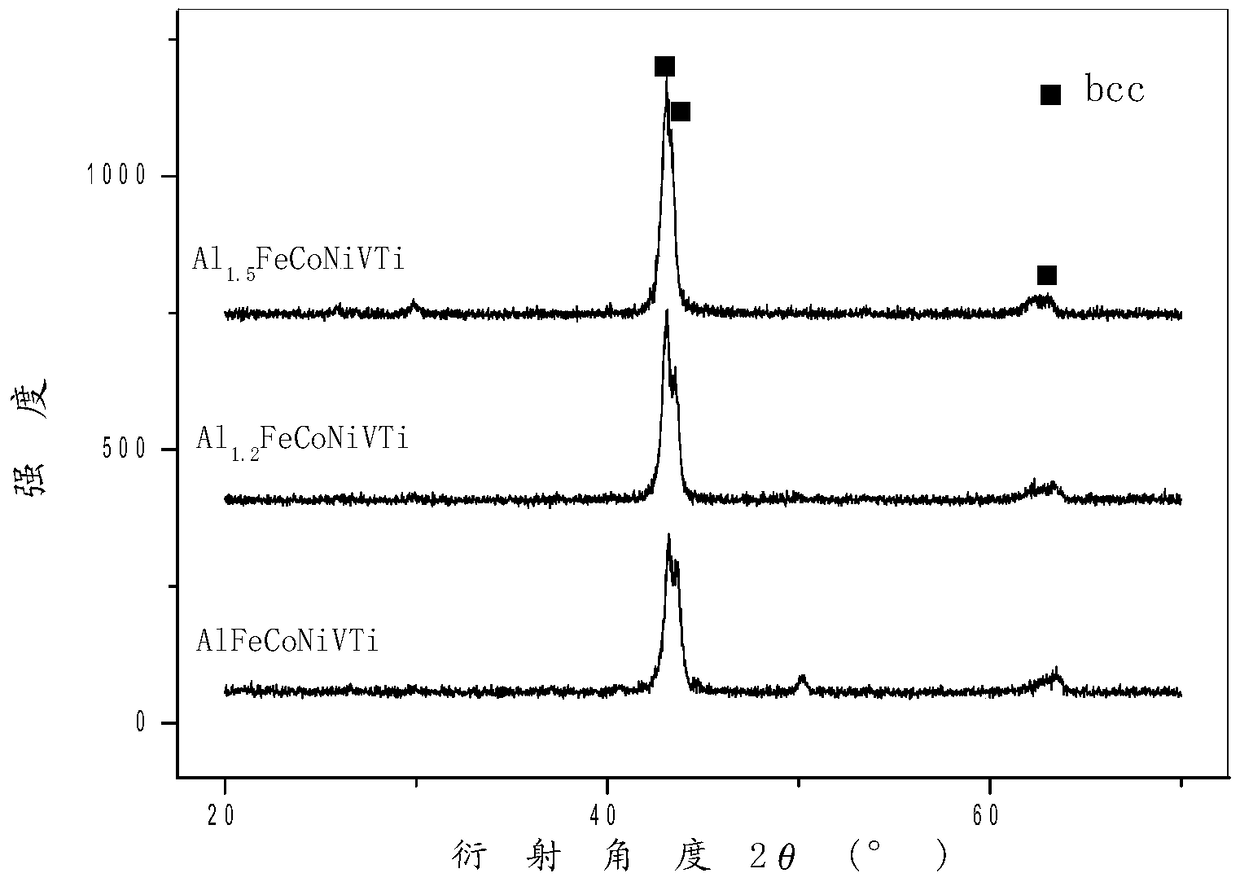

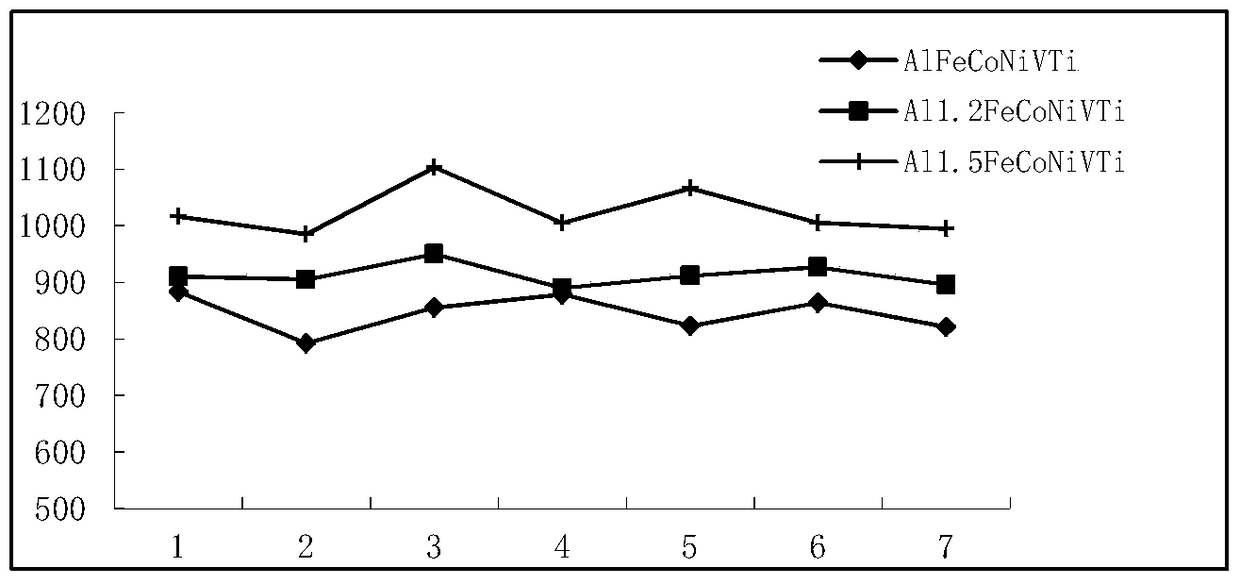

[0029] Example 1 takes the preparation of an AlFeCoNiVTi high-entropy alloy coating as an example, and the preparation process is as follows:

[0030] The first step: Al, Fe, Co, Ni, V, Ti six powders with a particle size of 5-30 μm and a purity of not less than 99.9%, according to an equimolar ratio of Al: Fe: Co: Ni: V: Ti = 1 :1:1:1:1:1 Weigh and mix, put into ball mill for 3 hours.

[0031] Step 2: put the ball-milled powder into a drying oven, and dry it at a temperature range of 100-120°C for 2 hours.

[0032] The third step: Q235 steel plate can be used as the base material, and the oil is removed by alkali washing, and then 40 mesh brown corundum is used for sandblasting and rust removal, and the air pressure of sandblasting is 0.5-0.7MPa.

[0033] Step 4: Preset the ball-milled and dried powder evenly on the surface of the Q235 steel plate with a thickness of 0.2mm for the pre-alloyed powder. Using YGA solid-state laser for multi-pass laser irradiation, the specific...

Embodiment 2

[0036] Example 2 to prepare Al 1.2 Taking FeCoNiVTi high-entropy alloy coating as an example, the preparation method is as follows:

[0037] The first step: Al, Fe, Co, Ni, V, Ti six powders with a particle size of 5-30 μm and a purity of not less than 99.9%, according to the molar ratio Al:Fe:Co:Ni:V:Ti=1.2:1 :1:1:1:1 Weigh and mix, put into ball mill and mill for 4 hours.

[0038] Step 2: put the ball-milled powder into a drying oven, and dry it at a temperature range of 100-120°C for 2 hours.

[0039] The third step: choose 12CrMo low-alloy steel plate as the base material, wash with alkali to remove oil, and then use 40 mesh brown corundum to sandblast and remove rust, and the air pressure of sandblasting is 0.5-0.7MPa.

[0040] Step 4: evenly place the ball-milled and dried powder on the surface of the 12CrMo low-alloy steel plate, and the thickness of the alloy powder is 0.2mm. Using YGA solid-state laser for multi-pass laser irradiation, the specific process paramete...

Embodiment 3

[0043] Example 3 to prepare Al 1.5 Taking FeCoNiVTi high-entropy alloy coating as an example, the preparation method is as follows:

[0044] The first step: Al, Fe, Co, Ni, V, Ti six powders with a particle size of 5-30 μm and a purity of not less than 99.9%, according to the molar ratio Al:Fe:Co:Ni:V:Ti=1.5:1 :1:1:1:1 Weigh and mix, put into ball mill for 2 hours.

[0045] Step 2: put the ball-milled powder into a drying oven, and dry it at a temperature range of 100-120°C for 2 hours.

[0046] The third step: choose Cr13Ni5 martensitic stainless steel plate as the base material, wash with alkali to remove oil, and then use 40 mesh brown corundum to sandblast and remove rust, and the air pressure of sandblasting is 0.5-0.7MPa.

[0047] Step 4: The ball-milled and dried powder is evenly placed on the surface of the stainless steel plate, and the thickness of the alloy powder is 0.3 mm. Using YGA solid-state laser for multi-pass laser irradiation, the specific process parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com