a high mg 2 Si aluminum alloy and its design and rapid solidification preparation method and application

An aluminum alloy, al-70%mg2si technology, applied in heat treatment equipment, semiconductor/solid-state device parts, manufacturing tools, etc., can solve the problems of low mechanical properties of materials, large thermal expansion coefficient, low Si phase content, etc. Effects of improved performance, reduced density, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

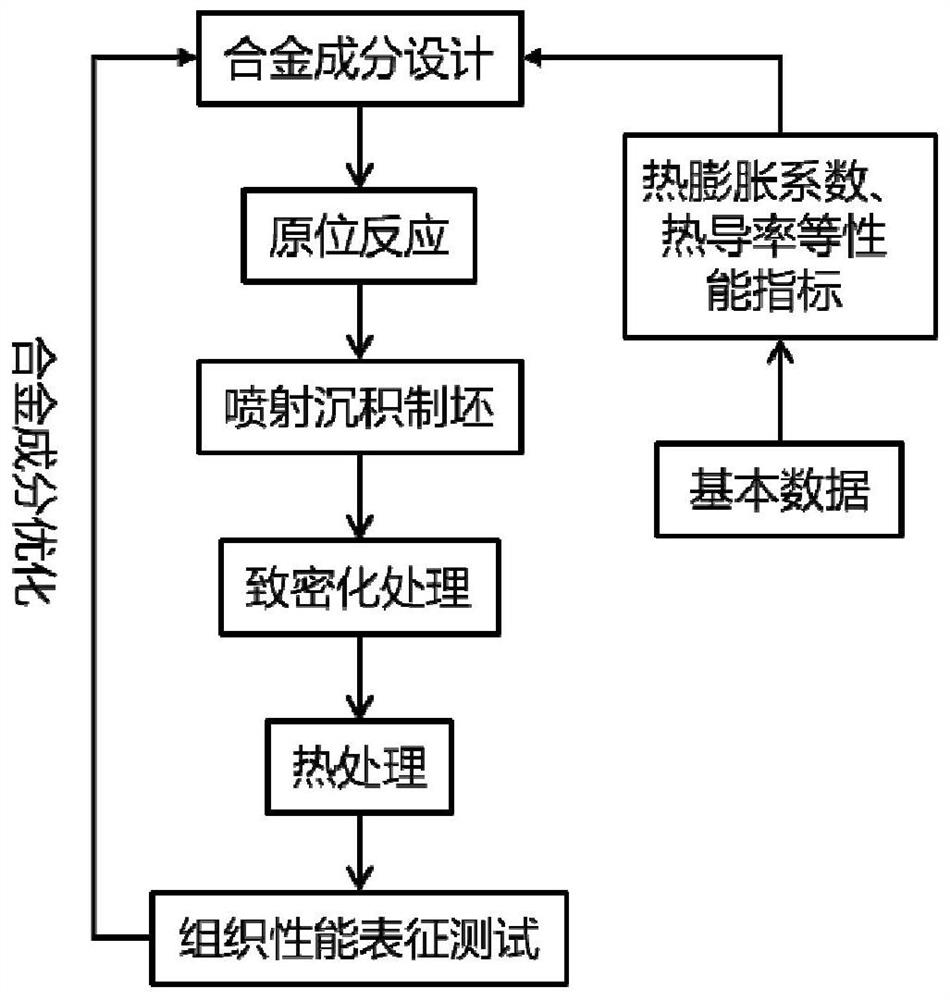

[0057] In this embodiment, a kind of Al-0.3%Mn-30%Mg 2 For the design, preparation and application of Si alloy electronic packaging cover materials, please refer to the attached figure 1 ,Specific steps are as follows:

[0058] (1) Alloy composition design: performance index requirements of electronic packaging materials and Al and Mg 2 Performance parameters of Si (Table 1), design Mg 2 Si content and Al matrix composition.

[0059] According to the requirement of thermal expansion coefficient of electronic packaging cover plate material at 20~200℃ 18.0±1.0×10 -6 / K, the thermal conductivity is required to be higher than 150W / mK.

[0060] First, according to the coefficient of thermal expansion 18.0±1.0×10 -6 / K requirements and formula (1), assuming Mg 2 Si content is x, then Al content is 1-x, namely

[0061] 23.6·(1-x)+7.5·x=18±1 (3)

[0062] From formula (3), it can be obtained that Mg 2 The Si content of 28.6%-41.0% can meet the requirements of the thermal expan...

Embodiment 2

[0087] A kind of Al-60%Mg in this embodiment 2 For the design, preparation and application of Si alloy electronic package housing materials, please refer to the attached figure 1 ,Specific steps are as follows:

[0088] (1) Alloy composition design: performance index requirements of electronic packaging materials and Al and Mg 2 Performance parameters of Si (Table 1), design Mg 2 Si content and Al matrix composition.

[0089] According to the requirement of thermal expansion coefficient of electronic package shell material at 20~200℃, it should be 13.0±1.0×10 -6 / K, the thermal conductivity is required to be higher than 100W / mK.

[0090] First, according to the coefficient of thermal expansion 12.0±1.0×10 -6 / K requirements and formula (1), assuming Mg 2 Si content is x, then Al content is 1-x, namely

[0091] 23.6·(1-x)+7.5·x=13±1 (5)

[0092] From formula (5), it can be obtained that Mg 2 The Si content of 59.6%-72.0% can meet the requirements of the thermal expansi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com