A light al-si-mg 2 si electronic packaging material and its preparation method and application

An al-si-mg2si, electronic packaging material technology, applied in the direction of circuit, additive manufacturing, additive processing, etc., can solve the problems of large size, split matrix, reduce material mechanical properties and processing performance, etc., to achieve density reduction, combination Good effect of avoiding component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

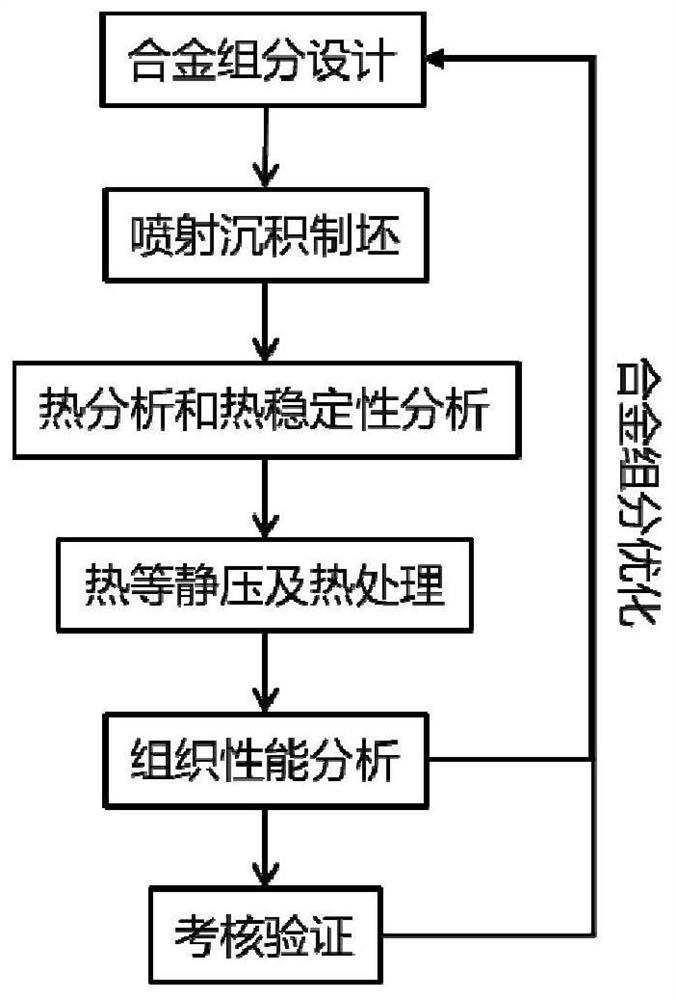

[0055] Prepare a kind of light Al-2%Si-25%Mg in the present embodiment 2 Si alloy electronic package cover material, please refer to the attached figure 1 ,Specific steps are as follows:

[0056] S1: Alloy composition design: The main performance index of the electronic packaging cover plate is the thermal expansion coefficient of 18.0±1.0 ×10 -6 / K and thermal conductivity ≥150W / mK, combined with Al, Si and Mg 2 The performance parameters of Si (Table 1), first design the Si content in Al-Si alloy according to formula (1) and formula (2), then use formula (3) and formula (4) to design Al-Si-Mg 2 Mg in Si alloy 2 The proportion of Si and Si phase.

[0057] First, according to the coefficient of thermal expansion 18.0±1.0×10 -6 / K requirements and formula (1), assuming Si content is x, then Al content is 1-x, namely

[0058] 23.6·(1-x)+4.2·x=18±1 (5)

[0059] From the formula (5), it can be obtained that the Si content of 23.7%-34.0% can meet the requirement of thermal e...

Embodiment 2

[0091] Prepare a kind of light Al-25%Si-25%Mg in the present embodiment 2 Si alloy electronic packaging shell material, please refer to the attached figure 1 ,Specific steps are as follows:

[0092] S1: Alloy composition design: The main performance index of the electronic packaging shell is the thermal expansion coefficient of 12.0±1.0 ×10 -6 / K and thermal conductivity ≥120W / mK, combined with Al, Si and Mg 2 The performance parameters of Si (Table 1), first design the Si content in Al-Si alloy according to formula (1) and formula (2), then use formula (3) and formula (4) to design Al-Si-Mg 2 Mg in Si alloy 2 The proportion of Si and Si phase.

[0093] First, according to the coefficient of thermal expansion 12.0±1.0×10 -6 / K requirements and formula (1), assuming Si content is x, then Al content is 1-x, namely

[0094] 23.6·(1-x)+4.2·x=12±1 (9)

[0095] It can be obtained from formula (9), that the Si content of 54.6% to 64.9% can meet the requirement of thermal expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com